Cryogenic Freezer

When liquid nitrogen transforms from liquid to gas, it absorbs a large amount of heat, leading to extremely low temperatures (-192℃ at the lowest) and making it the perfect method to incorporate in our cryogenic freezers. With its rapid freezing speed, the cryogenic freezer works well for products in need of a quickly hardened surface, such as the outer layer of a chocolate cake or thinly sliced mutton. Because it takes up so little space and needs little maintenance, the cryogenic freezer can be used for small-scale production or start-up companies with limited space.

For ten years, Aeroasia has been designing and manufacturing products for the food freezing equipment industry. With our professional and practical experience, we can also design tailor-made cryogenic freezers to fit your space, your products, and your needs.

Cryogenic Freezer Type

1.Straight tunnel: for thin or diced products in need of a short freezing time

2. Spiral: for products in need of long holding time or for facilities with limited floor space.

| Mechanical | Cryogenic | |

| Capital | High | Low |

| Energy | Low | High |

| Maintenance | High | Low |

| Dehydration | High | Low |

| Flexibility | Low | High |

| Turn-up capacity | Low | High |

| Capacity | 10 -1000 kg/hr (20-2000lb/hr) |

| Belt width | 200-2000mm(10"-80") |

| Power requirement | 380-560V, 50-60Hz, 3Ph |

| Liquid nitrogen temp. | -120 ℃ |

| Room temp. | -60 ℃ |

Features of Cryogenic Freezer

1. Designed to last at least 20 years, this cryogenic freezer has a seamlessly welded and enclosed floor and wall and thick SS304 panels. | 2. Well-made structure and quality materials keeps outside bacteria to a minimum. | |

3. Made to withstand low temperatures, it is highly efficient in its power usage and easy to clean. | ||

4. Comes with an optional CIP automatic cleaning system. | ||

5. Designed for easy and painless installation on-site, the liquid nitrogen freezer is dissembled into several sections for shipping. | ||

6. Adjustable settings means you can set the belt speed, freezing temperature, and volume of liquid nitrogen to what you need. A gas exhaust controlled by pressure and temperature leads to less liquid nitrogen being used, thus lowering your costs. | ||

Main Options

Single Drum Spiral Double Drum Spiral Twin Belt Spiral

Configuration Floor Plan

360° 90° 180°270°

Applications of Cryogenic Freezer

Poultry and livestock industry: chicken breast, beef slice, lamb slice, beefsteak, etc.

Baking industry: chocolate cake, ice cream cake, mousse cake, and other soft cakes needing to be frozen quickly or shaped in a short time.

Ice cream industry: ice cream quick freeze, chocolate layer fast shaping.

Seafood industry: salmon, tuna, fish fillet, lobster, sea crab and other sea products.

Links:https://globefindpro.com/products/73209.html

-

Multipass Tunnel Freezer

Multipass Tunnel Freezer

-

VRV Air Conditioning Unit

VRV Air Conditioning Unit

-

Synthetic Fiber Bag (Bags with Custom Printed Pattern)

Synthetic Fiber Bag (Bags with Custom Printed Pattern)

-

PVC Bag (Custom Plastic Bag as Packaging and Shopping Bag)

PVC Bag (Custom Plastic Bag as Packaging and Shopping Bag)

-

Oven Mitt ( Mitts with Silver Coated Surface )

Oven Mitt ( Mitts with Silver Coated Surface )

-

Non-Woven Bag (Eco-friendly Bag with Custom Shapes)

Non-Woven Bag (Eco-friendly Bag with Custom Shapes)

-

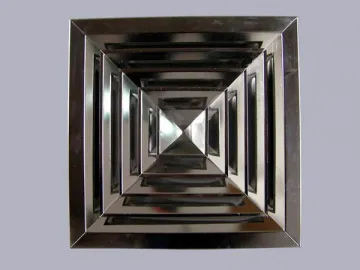

Stainless Steel Air Diffuser

Stainless Steel Air Diffuser

-

Kitchen Textile Set (Textile with Silver Coated Surface for Thermal Insulation)

Kitchen Textile Set (Textile with Silver Coated Surface for Thermal Insulation)

-

800-3200T Hot Press Machine (Heavy Duty)

800-3200T Hot Press Machine (Heavy Duty)

-

Kitchen Textile Set (Textile with Leopard Pattern)

Kitchen Textile Set (Textile with Leopard Pattern)

-

500T Hot Press Machine (for Decorative Veneered Panel)

500T Hot Press Machine (for Decorative Veneered Panel)

-

Cotton Bag (Custom Size Bags as Shopping Bag, Gift Bag)

Cotton Bag (Custom Size Bags as Shopping Bag, Gift Bag)