800-3200T Hot Press Machine (Heavy Duty)

JINLUN's 800-3200T hot press machine is ideal for use in furniture factories and artificial board secondary processing (major veneering) factories for pressing building partitions, wooden panels, etc. In particular, this high pressure hot pressing machine works well for manufacturing plywood for wood floors which require a higher degree of pressure to adhere more tightly for a stronger and more durable floor. The hot press also works for drying and leveling, particularly decorative wood chip leveling.

JINLUN has always been committed to providing comprehensive plywood production solutions. Our efficient and quality hot presses are the result of years of research and experience in manufacturing plywood production machinery.

Structural Features of 800-3200T Hot Press Machine

1. Heating Platen

The heating platen is made from a carbon steel plate with drilled holes for strength and durability. A working table of 2700mm×1370mm allows users to easily operate the wood working machine.

2. Heating System

The hot press comes with a special heating system which employs a heat transference oil boiler that features a countercurrent flow and a high temperature, and lowers the system pressure to meet safety requirements. The heat system's closed circulation transfers energy via liquid, thus reducing heat loss and saving overall energy.

3. Hydraulic System

This type of hot press is a hydraulic plywood press with adjustable hydraulic pressure.

4. Oil Cylinder

The oil cylinder is made with high precision tools, and sealants prevent oil from leaking.

5. Control System

Our hot press is equipped with a microcomputer control system for both manual and automatic control. With a simple push of a button you can control a whole set of processes including pressing plate ascending, closing, pressure adding, pressure maintaining, timing and pressing plate descending.

Technical Parameters of 800-3200T Hot Press Machine

| Model | BY22-4 ×8/80-15 |

| Plunger cylinder quantity and diameter | 4pcs; Φ320mm |

| Cylinder stroke | 1050mm |

| No-load closing time | About 34s |

| Hydraulic system | Manual and automatic control (with international warranty service) |

| Proof pressure | 25MPa |

| Main motor power | 11Kw |

| Pressing motor power | 7.5Kw |

| Main oil pump | 2 Shanghai Airlines 250 oil pumps |

| Pressing oil pump | 25ml/rev |

| Perforated plate size | 2700 ×1370 ×52mm (CE Authentication) |

| Place of origin of perforated plate | Kunshan, China |

| Interlayer spacing | 70mm |

| Mainframe size | 3560 ×1370 ×4660mm |

| Mainframe steel plate thickness | 40mm, 22mm and 12mm |

| Upper, lower and moved cross beam height | 1000mm, 1000mm and 400mm |

Related Names

Pressing Machine | Woodworking Machine | Cold Press Machine

Links:https://globefindpro.com/products/73206.html

-

Kitchen Textile Set (Textile with Silver Coated Surface for Thermal Insulation)

Kitchen Textile Set (Textile with Silver Coated Surface for Thermal Insulation)

-

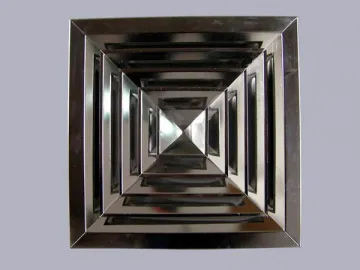

Stainless Steel Air Diffuser

Stainless Steel Air Diffuser

-

Cryogenic Freezer

Cryogenic Freezer

-

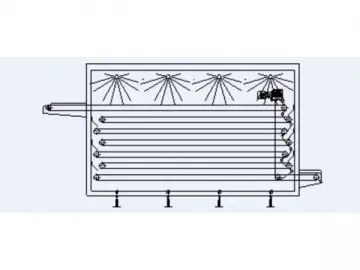

Multipass Tunnel Freezer

Multipass Tunnel Freezer

-

VRV Air Conditioning Unit

VRV Air Conditioning Unit

-

Synthetic Fiber Bag (Bags with Custom Printed Pattern)

Synthetic Fiber Bag (Bags with Custom Printed Pattern)

-

Kitchen Textile Set (Textile with Leopard Pattern)

Kitchen Textile Set (Textile with Leopard Pattern)

-

500T Hot Press Machine (for Decorative Veneered Panel)

500T Hot Press Machine (for Decorative Veneered Panel)

-

Cotton Bag (Custom Size Bags as Shopping Bag, Gift Bag)

Cotton Bag (Custom Size Bags as Shopping Bag, Gift Bag)

-

Spiral Oven

Spiral Oven

-

Debarker (with Horizontal Spindle)

Debarker (with Horizontal Spindle)

-

Debarker (for 8 Feet Log)

Debarker (for 8 Feet Log)