500T Hot Press Machine (for Decorative Veneered Panel)

JINLUN's 500T hot press machine is our newly launched plywood making machine, specially designed for international markets. Ideal for use in furniture factories and artificial board secondary processing (major veneering) factories for pressing building partitions, wooden panels, decorative veneered panels, etc., this hot pressing machine bonds furniture plates, building partitions and wooden doors, and it laminates decorative materials such as cloths, veneer, and PVCs to various artificial boards including plywood, core-board, MDF and chipboard.

The hot press also works for drying and leveling, particularly decorative wood chip leveling. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.

Additionally, it's easy to dissemble and assemble for inexpensive shipping.

JINLUN has long seen the potential of hot presses in a wide range of industries and invests in research and design to continually upgrade our machinery's features for more efficient and better quality machines.

Structural Features of 500T Hot Press Machine

1. Heating Platen

The heating platen is made from a carbon steel plate with drilled holes for strength and durability. A working table of 2700mm×1370mm allows users to easily operate the wood working machine.

2. Heating System

The hot press comes with a special heating system which employs a heat transference oil boiler that features a countercurrent flow and a high temperature, and lowers the system pressure to meet safety requirements. The heat system's closed circulation transfers energy via liquid, thus reducing heat loss and saving overall energy.

3. Hydraulic System

This type of hot press is a hydraulic plywood press with adjustable hydraulic pressure.

4. Oil Cylinder

The oil cylinder is made with high precision tools, and sealants prevent oil from leaking.

5. Control System

Our hot press is equipped with a microcomputer control system for both manual and automatic control. With a simple push of a button you can control a whole set of processes including pressing plate ascending, closing, pressure adding, pressure maintaining, timing and pressing plate descending.

Technical Parameters of 500T Hot Press Machine

| Model | BY22-4×8/40-15 |

| Plunger cylinder | 2pcs, Φ 320mm |

| Cylinder stroke | 1050mm |

| No-load closing time | About 27s |

| Hydraulic system | Manual and automatic control (with international warranty service) |

| Proof pressure | 25Mpa |

| Main motor power | 11Kw |

| Pressing motor power | 5.5Kw |

| Main oil pump | Shanghai Airlines 250 oil pump |

| Pressing oil pump | 10ml/rev |

| Perforated plate size | 2500 ×1300 ×42mm (CE Authentication) |

| Interlayer spacing | 70mm |

| Mainframe steel plate thickness | 40mm, 22mm and 12mm |

| Upper, lower and moved cross beam height | 1000mm,1000mm and 400mm |

| Main frame size | 3600 ×1370 ×4790mm |

| Moved cross beam steel plate thickness | 22mm |

| Moved cross beam size | 2700 × 1370 × 400mm |

| Frame | Full assembly frame |

Related Names

400T | 500T | Wood Based Panel | Sheet Machine | Machine For Door | Wooden Door Machine

Links:https://globefindpro.com/products/73204.html

-

Kitchen Textile Set (Textile with Leopard Pattern)

Kitchen Textile Set (Textile with Leopard Pattern)

-

800-3200T Hot Press Machine (Heavy Duty)

800-3200T Hot Press Machine (Heavy Duty)

-

Kitchen Textile Set (Textile with Silver Coated Surface for Thermal Insulation)

Kitchen Textile Set (Textile with Silver Coated Surface for Thermal Insulation)

-

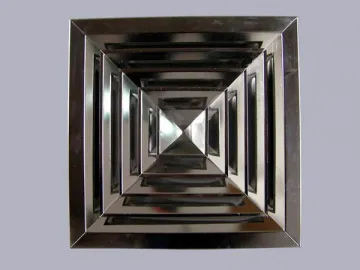

Stainless Steel Air Diffuser

Stainless Steel Air Diffuser

-

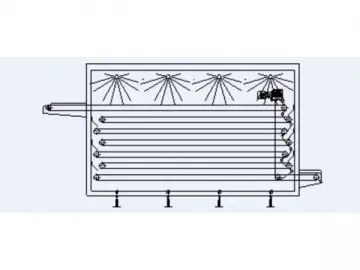

Cryogenic Freezer

Cryogenic Freezer

-

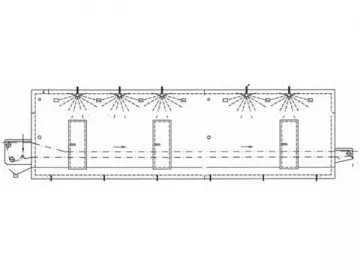

Multipass Tunnel Freezer

Multipass Tunnel Freezer

-

Cotton Bag (Custom Size Bags as Shopping Bag, Gift Bag)

Cotton Bag (Custom Size Bags as Shopping Bag, Gift Bag)

-

Spiral Oven

Spiral Oven

-

Debarker (with Horizontal Spindle)

Debarker (with Horizontal Spindle)

-

Debarker (for 8 Feet Log)

Debarker (for 8 Feet Log)

-

Veneer Lathe (for 4 Feet Log, Spindle-Less)

Veneer Lathe (for 4 Feet Log, Spindle-Less)

-

Straight Tunnel Freezer

Straight Tunnel Freezer