Aluminum Alloy Oil Tank Semi-Trailer

Made of aluminum alloy extrusions, our aluminum alloy oil tank semi-trailer features excellent elongation and high strength. We adopt the closed filling system, which doubles the efficiency of conventional loading and unloading.

Research shows that in the unloaded condition, the fuel consumption of vehicle’s curb weight accounts for 60% of the total fuel consumption. The lighter tank trailer generates less fuel consumption and saves more money. For example, if a tank truck is 1 ton lighter, it can save about 0.6L fuel in every 10 km. Being 4 tons lighter than other conventional semi-trailers, our aluminum tank semi-trailer can save a considerable amount of fuel and bring more economic benefit.

Features of Aluminum Alloy Oil Tank Semi-Trailer

1. Light Weight

The density of aluminum is less than 35% of the conventional carbon steel’s, correspondingly, our aluminum alloy fuel tank trailer has not only lower center of gravity, but also outstandingly light weight. The light aluminum alloy oil tank semi-trailer can have much more payload capacity and bring higher economic efficiency. It is a significant development trend in the logistics industry.

2. Closed Loading and Unloading System

When the oil tank trailer is loading and unloading, the discharged oil vapor's concentration is up to 50%. However, the oil vapor is the main cause of the urban haze pollution. The closed loading and unloading system of our aluminum alloy oil tank semi-trailer can have oil vapor recovery and restore the oil vapor into fuel oil, which can reduce the pollution and waste. Importantly, it has become the nationally regulated essential device.

3. Safe and Stable ABS & EBS System

The safe and stable ABS & EBS system of our aluminum alloy oil tank semi-trailer executes real-time monitoring to your driving condition. If the system detects the vehicle is going to be out of control, the system will apply braking force to specific wheels. It can help you to safely drive on the correct track and prevent the vehicle's loss of control or rollover.

4. Air Suspension

Being the standard facility of our aluminum alloy oil tank semi-trailer, the air suspension can provide the best damping effect. Moreover, the height of our aluminum alloy oil tank semi-trailer's body is adjustable.

5. Lifting and Turning Suspension System

The lifting and turning suspension system of our aluminum alloy oil tank semi-trailer can substantially reduce the tire wear. The test shows that vehicles using this kind of suspension system have the driving distance up to 750,000km, which is as twice as that of the vehicles using conventional suspension system. Obviously, the lifting and turning suspension system of our aluminum alloy oil tank semi-trailer can largely reduce the cost of tire wear for the logistics companies.

Comparison between Aluminum Alloy Oil Tank Semi-Trailer and Conventional Carbon Steel Tank Semi-Trailer

| Aluminum Alloy Oil Tank Semi-Trailer | Carbon Steel Tank Semi-Trailer | Added Value of Aluminum Alloy Oil Tank Semi-Trailer | Examples | |

| Light Weight | Minimum 6,600KG | 10,000KG or above | The loading capacity triples and quadruples;overloading avoided | The 3-Axle Semi-trailer |

| Tire Wear | Up to750,000KM | No more than 300,000 KM | Up to 60% reduction | The Michelin Tire |

| Fuel Consumption | 28-36L | 35-50L | Up to 15% reduction | The fuel consumption of general hundred kilometers |

Parameters

Description

Aluminum Alloy Oil Tank Semi-Trailer

Effective Volume: 45m3

Aluminum alloy 3-axle, Single Tire

Ladder rack is available to be installed in the front or rear

ABS Manufacturer: Zhejiang VIE Guangzhou KORMEE WABCO

Ground Clearance (MM): 500

Gross Weight (KG): 39,950

Curb Weight (KG): 6,950

Rated Payload (KG): 33,000

External Dimension (L×W×H) (MM) :12,600×2,490×3,650

External Length of Tank (MM): 3,750

Wheelbase (MM): 7,000 1,350 1,350

Track (MM): 2,040

Links:https://globefindpro.com/products/73487.html

-

Welded Steel Chain (German Standard)

Welded Steel Chain (German Standard)

-

Dump Truck

Dump Truck

-

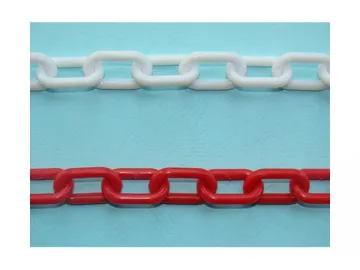

Plastic Chain

Plastic Chain

-

Grade 80 Lifting Chain

Grade 80 Lifting Chain

-

Refrigerated Truck Body

Refrigerated Truck Body

-

Carbon Steel Oil Tank Semi-Trailer

Carbon Steel Oil Tank Semi-Trailer

-

Welded Steel Chain, Korean Standard

Welded Steel Chain, Korean Standard

-

Truck with Interchangeable Container

Truck with Interchangeable Container

-

Welded Steel Chain, Australian Standard

Welded Steel Chain, Australian Standard

-

Weldless Steel Chain (Double Hook Link Chain)

Weldless Steel Chain (Double Hook Link Chain)

-

Concentric Reducer

Concentric Reducer

-

Stainless Steel Chain

Stainless Steel Chain