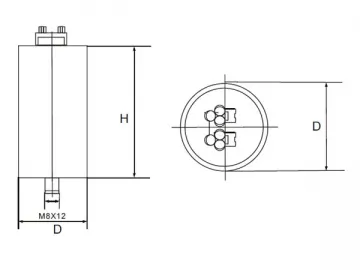

CD239 Series High Current Capacitor

In the capacitor industry, the material deformation and corrosion at high temperature are two serious problems, many engineers cope with these issues by choosing CD239 series high current capacitor. As a kind of anticorrosive capacitor, the CD239 capacitor can work at 85℃ for 3000 hours, and 105℃ for 2000 hours

At high temperature, the size change is mainly affected by the creeping strength. This means that we can choose better material to extend the product's service life, and choose thinner material to lower the cost. Following these theories, our CD239 series high current capacitor has acquired excellent performance.

The CD239 high temperature capacitor features high rated ripple current and desirable reliability. It is typically suitable for being used as capacitor for frequency conversion current converter, power switch capacitor, welding machine capacitor, television capacitor, and so on.

Technical Features| Item | Feature | |

| Operating temperature | -25℃~ 85℃ | -25℃~ 105℃ |

| Rated operational voltage | 250-450V (DC) | |

| Rated capacitance | 220-1000μF | |

| Rated capacitance allowance | ±20℃ (20℃, 120Hz) | |

| Leakage current | I≤0.02CU (μA) or 3mA (the smaller one, determined in 1 min) | |

| Loss tangent (Tgδ) | Tgδ≤0.15 | |

| Ripple current allowance | See the forms below | |

| Durability | At 85℃ or 105℃, exert rated voltage on the capacitor to achieve rated ripple current for 3000 hours or 2000 hours. Then after 24 hours of restoring, the capacitance changing rate is equal to or less than ±20% of the initial value | |

| Tgδ≤120% standard value | ||

| leakage current I≤200% standard value | ||

| High temperature storage | 85℃ or 105℃, 96 hour storage with zero load, then recovers for 16 hours | |

| Capacitance change≤±20% initial value | ||

| Tgδ≤120% standard value | ||

| Leakage current I≤200% standard value | ||

Ripple current correction coefficient Coefficient of frequency

| Frequency (Hz) | 50 | 120 | 500 | 1K | 10-50K |

| Coefficient | 0.8 | 1 | 1.05 | 1-1 | 1.15 |

| Temperature (℃) | ≤65 | 85 | 105 |

| Coefficient | 1.3 (1.5) | 1.0 (1.7) | 1 |

Standards: GB/T 5993-2003/1EC 60384-4:1998

The table of rated capacitance, rated voltage, surge current, rated ripple current, and dimensions.

| UR (v) | 250 | 350 | 400 | 450 | ||||||||

| SR (v) | 300 | 400 | 450 | 500 | ||||||||

| CR (μF) | DXL | ir (A) | DXL | ir (A) | DXL | ir (A) | DXL | ir (A) | ||||

| mm | 85℃ | 105℃ | mm | 85℃ | 105℃ | mm | 85℃ | 105℃ | mm | 85℃ | 105℃ | |

| 220 | 30×40 | 1.35 | 1.25 | 30×40 | 1.40 | 1.10 | ||||||

| 330 | 30×40 | 1.80 | 1.25 | 30×40 | 1.80 | 1.40 | 30×50 | 1.70 | 1.30 | |||

| 470 | 30×40 | 1.80 | 1.60 | 30×50 | 2.10 | 1.50 | 35×50 | 2.15 | 1.80 | 35×50 | 2.30 | 1.70 |

| 560 | 30×40 | 2.00 | 1.70 | 35×50 | 2.40 | 1.70 | 35×50 | 2.30 | 2.05 | 35×60 | 2.50 | 1.80 |

| 680 | 30×50 | 2.35 | 2.00 | 35×50 | 2.70 | 2.10 | 35×60 | 2.45 | 2.15 | |||

| 820 | 30×50 | 2.70 | 2.30 | 35×60 | 2.90 | 2.40 | ||||||

| 1000 | 30×60 | 3.20 | 2.80 | |||||||||

Links:https://globefindpro.com/products/76729.html

-

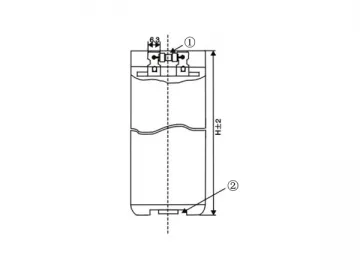

CBB80 Series Dry Capacitor, Immersed Capacitor

CBB80 Series Dry Capacitor, Immersed Capacitor

-

CD60 Series Starting Capacitor

CD60 Series Starting Capacitor

-

CBB61 Series Polypropylene Film Capacitor

CBB61 Series Polypropylene Film Capacitor

-

UV Air Purifiers

UV Air Purifiers

-

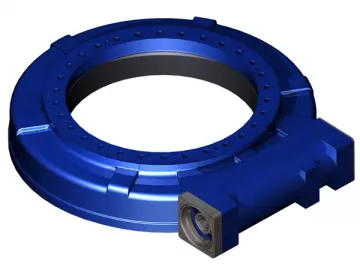

HSE Series Single Worm Slewing Drive

HSE Series Single Worm Slewing Drive

-

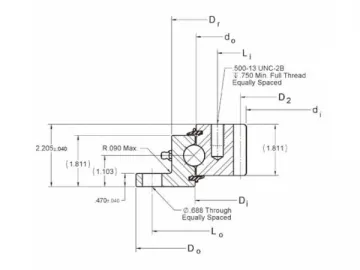

RK Series Four Point Contact Ball Bearing

RK Series Four Point Contact Ball Bearing

-

Wall Mounted UV Lamp

Wall Mounted UV Lamp

-

Movable UV Lamp

Movable UV Lamp

-

Underarm Crutch

Underarm Crutch

-

Double Ended Germicidal Lamps (Preheat Start) - T6 2P

Double Ended Germicidal Lamps (Preheat Start) - T6 2P

-

CBB60 Series Running Capacitor

CBB60 Series Running Capacitor

-

Double Ended Germicidal Lamps (Preheat Start) - T8 2P

Double Ended Germicidal Lamps (Preheat Start) - T8 2P