Plastic Pulverizer

The plastic pulverizer, or pulverizer mill, is designed to grind thermoplastics like PVC, PE, and ABS to finer sizes. A popular use of ourpulverizing equipment is in the recycling of PVC and PE pellets, and other plastic off-cuts. The resultant powder proves to be very useful in the plastic products manufacturing process, where plastic experts often add 20% to 30% of waste plastic powders to the ingredients without affecting the overall physical properties of finished plastic products. Therefore, the plastic pulverizer just provides an effective way of recycling plastic scraps and wastes while reducing the plastics production cost.

Features

1. Stationary grinding tables seldom require sharpening or replacement. When table change is necessary, the pulverizer allows for easy replacement and alteration.

2. New bearing technology provides high rotary speed.

3. This plastic pulverizer only uses one motor to ensure high-efficiency grinding. It saves the amount of time spent on operation and process control.

4. The motor offers high rotational speed and high-impact necessary to break down the plastic particles while consuming minimum power.

5. It is easy to precisely adjust the gap between grinding parts by means of feeler gauge and adjustment bolt. This grinding process yields ultra-fine powder of no more than 1000µm in diameter, without the need of screens.

Technical Specifications

| Plastic Pulverizer Model No. | SMP-380 | SMP-400 | SMP-450 | SMP-610 |

| Main Motor Power (kw) | 22 | 30 | 37 | 55 |

| Fan Power (kw) | 7.5 | 7.5 | 11 | 11 |

| Voltage | 380V ,50Hz | |||

| Total Power (kw) | 28 | 38 | 50 | 68 |

| Cutter Head Diameter (mm) | 380 | 400 | 450 | 610 |

| Feed Diameter (mm) | ≤6 | |||

| Material Fineness (mesh number) | 20-80 | |||

| Production Capacity (kg/h) | 50-150 | 80-180 | 80-200 | 100-300 |

Links:https://globefindpro.com/products/76798.html

-

Plastic Crusher

Plastic Crusher

-

Stainless Steel Kitchen Sink

Stainless Steel Kitchen Sink

-

Spiral Reinforced PVC Hose Extrusion Line

Spiral Reinforced PVC Hose Extrusion Line

-

PET/PBT Single Layer/Multi-layer Sheet Extrusion Line

PET/PBT Single Layer/Multi-layer Sheet Extrusion Line

-

PVC Hot-Cutting Granulating Line

PVC Hot-Cutting Granulating Line

-

PVC Water Supply Pipe/Drainage Pipe Extrusion Line

PVC Water Supply Pipe/Drainage Pipe Extrusion Line

-

Angle Valve

Angle Valve

-

Ceramic Toilet

Ceramic Toilet

-

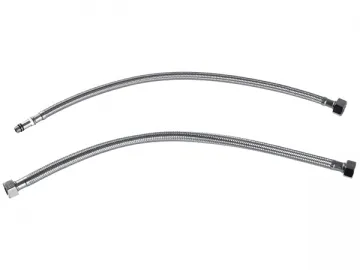

Shower Hose

Shower Hose

-

Flush Valve

Flush Valve

-

Ceramic Urinal

Ceramic Urinal

-

Fast on Faucet

Fast on Faucet