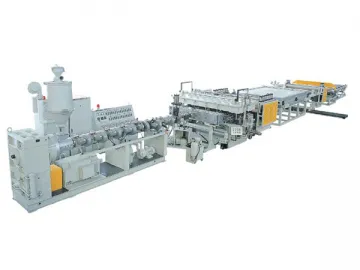

Single Side Cast Film Extrusion Lamination Line

This single-side cast film extrusion lamination line features a state-of-the-art extrusion laminating design that allows easy operation. The extruder adopts automatic temperature control, material feeding, and high-precision extrusion die to ensure extrusion quality.

Available with automatic tension control, the unwinding unit, lamination unit and take-up unit (winding unit) are in sync with each other. The winding unit takes up the laminate at the same high speed even when the laminate roll needs replacing. This greatly reduces machine downtime.

Other desirable features on this single-side cast film extrusion lamination line include variable-frequency drive, PLC human-machine interface, linkage control, corona treatment device, automatic deviation correction unit, finished laminate metering device, adjustable edge-cutter and edge guide.

Technical Specifications (SDFA)

| Extrusion Lamination Line Specifications | 950mm | 1150mm | 1350mm | 1750mm | 1950mm |

| Width | 800mm | 1000mm | 1200mm | 1650mm | 1800mm |

| Extruder Powder | 30KW | 30KW | 37 KW | 37 KW | 45 KW |

| Extruder Screw | Ø80 | Ø90 | Ø90 | Ø90 | Ø100 |

| Maximum Extrusion Output | 160kg/h | 180kg/h | 220kg/h | 240kg/h | 260kg/h |

| Resin | LDPE, LDPP laminating resin | ||||

| Base Material | Paper (35-350g/m2), non-woven fabric, woven cloth, aluminum foil | ||||

| Mechanical Speed | 80-120 m/min | ||||

| Coating Thickness | 0.012mm-0.05mm | ||||

| Diameter of Wound and Unwound Rolls | Ø1200mm-Ø1500mm (friction-type winding) | ||||

| Diameter of Auxiliary Unwound Rolls | Ø300mm---Ø450mm | ||||

| Variable Frequency Drive (for tension control) | Vector control variable frequency drive (automatic tension control) | ||||

| Electrical Control | PLC system with human-machine interface | ||||

| Dimensions (L×W×H) | 11000mm × 7000-9000mm × 3000mm | ||||

Links:https://globefindpro.com/products/76929.html

-

Biaxially Oriented Film Extrusion Line

Biaxially Oriented Film Extrusion Line

-

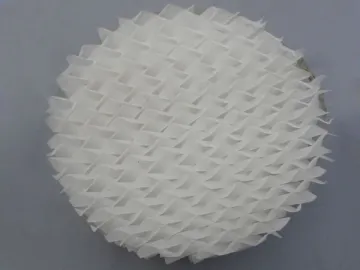

Plastic Structured Packing

Plastic Structured Packing

-

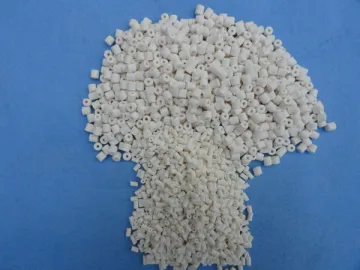

Dehydrogenation Catalyst

Dehydrogenation Catalyst

-

Plastic Random Packing

Plastic Random Packing

-

Twinwall/Multiwall Sheet Extrusion Line

Twinwall/Multiwall Sheet Extrusion Line

-

Hydrocarbon Conversion Catalyst Carrier

Hydrocarbon Conversion Catalyst Carrier

-

PC Suitcase Sheet Extrusion Line

PC Suitcase Sheet Extrusion Line

-

PVC Shrink Film Extrusion Line

PVC Shrink Film Extrusion Line

-

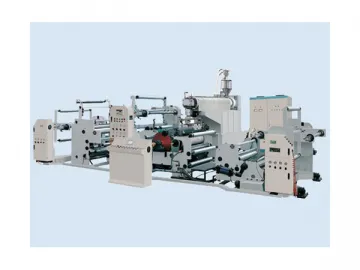

Multi-layer Cast Film Extrusion Lamination Line

Multi-layer Cast Film Extrusion Lamination Line

-

Compact Fluorescent Lamp

Compact Fluorescent Lamp

-

PVB Film Extrusion Line

PVB Film Extrusion Line

-

High Resistance Multi-Layer PE,EVOH,PA,EVA,PS,PP Sheet Extrusion Line

High Resistance Multi-Layer PE,EVOH,PA,EVA,PS,PP Sheet Extrusion Line