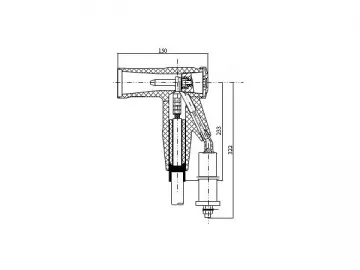

Cold Shrink Terminations

Introduction

1. Installation Preponderance

The W (N) LS-24KV/35KV cold shrink termination is applicable for either indoor or outdoor applications. This selection of cable termination adopts state-of-the-art cold shrink technology, and is designed with elastomer that will immediately stick to installation part once the conductor core inside the cold shrink terminal is extracted.

2. Material Superiority

We fabricate this cold shrink termination using superior silicone rubber insulation and German Dow Corning sizing material. Therefore, this product comes with merits like high elasticity, excellent leakproofness, good corrosion resistance and wonderful hydrophobicity.

3. Structural Advantage

This range of cold shrink terminations is designed in pre-expanded structure. It can maximally cover conductors and requires no fire or friction for installation, making for installation convenience and low cost.

Meanwhile, the one-piece stress control unit and terminal bushing, fabricated via injection molding, is designed in geometrical shape, effectively relieving electric filed stress concentration degree at the end of cable semiconducting layer. If three-core cable is used, we can provide you cold shrink insulating tube and unique three core pull-over tabs.

Distinctions between Indoor and Outdoor Types Cold Shrink Terminations

Whereas there is less pollutants indoors, the indoor cold shrinkable terminal comes with smaller blade. While, the outdoor type is designed with larger blade considering that there are more pollutants outdoors and also there is need for increasing security creepage distance.

Reference Standards

Our cold shrink terminations are made conforming to IEC60502, IEEE48 and GB/T12706 standards.

Application

1. You can apply this cold-shrink termination to 24KV/35kV XLPE single-core or three-core copper or aluminum conductor cable with 50-400mm2 sectional area.

2. This product is also applicable for cable with extrusion-type semiconducting layer for shielding.

3. It functions well in highly polluted, salty, foggy and humid areas, or in regions with high temperature differential.

Structure

| 1 | Cable lug |

| 2 | Cable lug cap |

| 3 | Conductor |

| 4 | Core insulation |

| 5 | Termination tube |

| 6 | Stress control unit |

| 7 | Semiconducting layer |

| 8 | Copper shielding tape |

| 9 | Color phase tube |

| 10 | Insulating tube |

| 11 | Cable Breakout |

| 12 | Constant force spring |

| 13 | Armouring |

| 14 | Sealing tape |

| 15 | Earthing copper strand |

| 16 | Cable |

Silicone Rubber

| Item | Unit | Index |

| Hardness | ° | 42 |

| Dielectric constant | ε | 2.8 |

| Tensile strength | MPa | ≥7.6 |

| Tear strength | KN/m | ≥33 |

| Elongation at break | % | ≥610 |

Connection Terminal

| Conductor sectional area(mm2) | Item No. | A | B | C | D | |

| Copper conductor | Aluminum conductor | |||||

| 50 | SSYTd123 | SSYLd123 | 10.00 | 14.00 | 49.00 | 19.00 |

| 70 | SSYTd124 | SSYLd124 | 12.00 | 16.00 | 54.00 | 22.00 |

| 95 | SSYTd125 | SSYLd125 | 13.00 | 18.00 | 54.00 | 22.00 |

| 120 | SSYTd126 | SSYLd126 | 15.00 | 21.00 | 54.00 | 22.00 |

| 150 | SSYTd127 | SSYLd127 | 16.00 | 23.00 | 64.00 | 26.50 |

| 185 | SSYTd128 | SSYLd128 | 18.00 | 25.00 | 64.00 | 26.50 |

| 240 | SSYTd129 | SSYLd129 | 20.00 | 28.00 | 64.00 | 26.50 |

| 300 | SSYTd130 | SSYLd130 | 22.00 | 31.00 | 69.00 | 32.50 |

| 400 | SSYTd131 | SSYLd131 | 25.00 | 35.00 | 69.00 | 32.50 |

Dimensions of Indoor and Outdoor Type Cold Shrink Terminations

| Conductor sectional area(mm2) | Item No. | Cable Insulation diameter range (mm) | ||

| Single core | Three core | Min. | Max. | |

| 50-185 | NLS1-24/35/1(indoor termination) WLS1-24/35/1 (outdoor termination) | NLS 1-24/35/3(indoor termination) WLS1-24/35/3 (outdoor termination) | 30.00 | 40.00 |

| 240-500 | NLS 2-24/35/1(indoor termination) WLS1-24/35/1 (outdoor termination) | NLS 2-24/35/3 (indoor termination) WLS1-24/35/3 (outdoor termination) | 40.00 | 50.00 |

Technical Parameters

| Item | Unit | Index |

| Rated voltage | kV | 24/35 |

| Rated frequency | Hz | 50 |

| 5-minute power frequency withstand voltage | kV | 117 |

| Partial discharge | PC/45kV | ≤10 |

| Impulse voltage test | kV | 200 |

| 15-minute DC withstand voltage test | kV | 104 |

Note

Please download PDF document for packing list information.

Cold Shrink Terminations

Links:https://globefindpro.com/products/77789.html

-

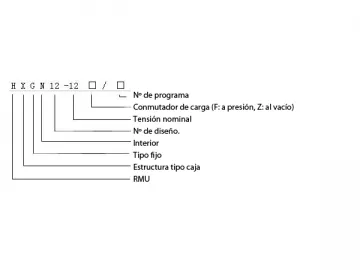

Medium Voltage Switchgear

Medium Voltage Switchgear

-

QY698 Tire Changer

QY698 Tire Changer

-

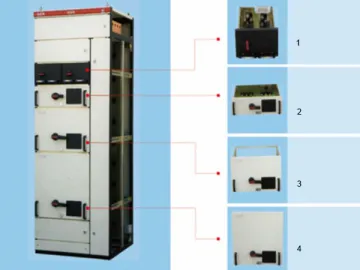

Low Voltage Switchgear (Withdrawable Type, Single Row)

Low Voltage Switchgear (Withdrawable Type, Single Row)

-

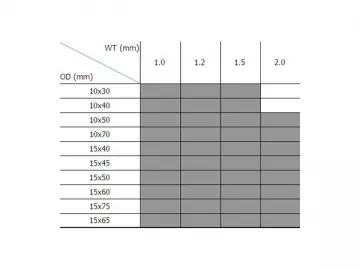

Rectangular Stainless Steel Tube

Rectangular Stainless Steel Tube

-

Plate Beveling Machine, GF-2046

Plate Beveling Machine, GF-2046

-

Post Insulator

Post Insulator

-

QY968 Wheel Balancer

QY968 Wheel Balancer

-

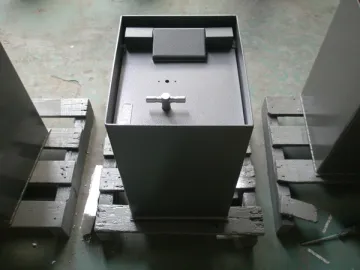

Drop Safes

Drop Safes

-

Unscreened Separable Connector (With Surge Arrester)

Unscreened Separable Connector (With Surge Arrester)

-

Fuse Cutout (12/15kV)

Fuse Cutout (12/15kV)

-

Reinforced Safes

Reinforced Safes

-

Underfloor Safes

Underfloor Safes