Suspension Insulator

Description

1. The suspension insulator adopts silicone rubber as fabricating material and boasts high elasticity, excellent leak tightness, corrosion resistance and remarkable hydrophobicity.

2. Superior special steel hardware is used for manufacturing this suspension type insulator, and we take advantage of eco-friendly pressure welding to realize uniform plastic deformation of the steel hardware.

3. This suspension insulator is especially suited for salty, foggy, high-altitude, high-temperature, highly humid, cold, seriously polluted areas. You can also apply the suspension composite insulator to mechanically tension loaded circuit, large-span and compact circuit.

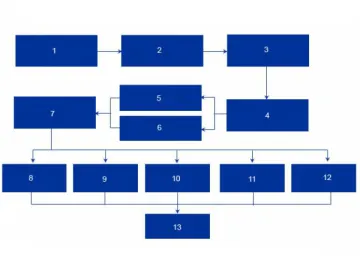

Production Flow of the Suspension Insulator

1. Raw material test

2. Pressure welding

3. Injection and vulcanization

4. Product test

5. Mechanical load test

6. Appearance inspection

7. Sampling test

8. Appearance and dimension

9. Mechanical load test

10. Galvanizing coat

11. Pin

12. Steep wave impact

13. Packaging and warehousing

Model Instruction

Service Environment

The suspension insulator can be used under following conditions:

1. Ambient temperature: -45℃ to 55℃

2. Altitude: ≤1000m

3. Rated frequency: 48Hz-62Hz

4. Wind pressure: ≤700Pa (equivalent to wind speed of 34m/s)

5. Air pollution level: Less than IV level

6. Power frequency voltage of arrester: Less than continuous running voltage of arrester

Technical Parameters of the Suspension Insulator

| No. | Model | Rated voltage (kV) | Rated mechanical tensionload (kN) | Conn-ectionsign | Structure height (mm) | Minimal electric arc distance (mm) | Minimal nominal creepage distance (mm) | Lightning full wave impulse withstandvoltage(kV) ≥ | 1-minutepower frequency withstand voltage (kV) ≥ |

| 1 | FXBW-10/70 | 10 | 70 | 16 | 420±15 | 185 | 480 | 165 | 50 |

| 2 | FXBW1-35/70 | 35 | 70 | 16 | 610±15 | 450 | 810 | 230 | 95 |

| 3 | FXBW2-35/70 | 35 | 70 | 16 | 650±15 | 450 | 810 | 230 | 95 |

| 4 | FXBW3-35/70 | 35 | 70 | 16 | 610±15 | 450 | 1015 | 230 | 95 |

| 5 | FXBW4-35/70 | 35 | 70 | 16 | 650±15 | 450 | 1015 | 230 | 95 |

| 6 | FXBW1-66/70 | 66 | 70 | 16 | 870±15 | 700 | 1450 | 410 | 185 |

| 7 | FXBW2-66/70 | 66 | 70 | 16 | 940±15 | 700 | 1450 | 410 | 185 |

| 8 | FXBW3-66/70 | 66 | 70 | 16 | 870±15 | 700 | 1900 | 410 | 185 |

| 9 | FXBW4-66/70 | 66 | 70 | 16 | 940±15 | 700 | 1900 | 410 | 185 |

| 10 | FXBW1-110/70 | 110 | 70 | 16 | 1180±15 | 1000 | 2520 | 550 | 230 |

| 11 | FXBW2-110/70 | 110 | 70 | 16 | 1240±15 | 1000 | 2520 | 550 | 230 |

| 12 | FXBW3-110/70 | 110 | 70 | 16 | 1180±15 | 1000 | 3150 | 550 | 230 |

| 13 | FXBW4-110/70 | 110 | 70 | 16 | 1240±15 | 1000 | 3150 | 550 | 230 |

| 14 | FXBW1-110/100 | 110 | 100 | 16 | 1180±15 | 1000 | 2520 | 550 | 230 |

| 15 | FXBW2-110/100 | 110 | 100 | 16 | 1240±15 | 1000 | 2520 | 550 | 230 |

| 16 | FXBW3-110/100 | 110 | 100 | 16 | 1180±15 | 1000 | 3150 | 550 | 230 |

| 17 | FXBW4-110/100 | 110 | 100 | 16 | 1240±15 | 1000 | 3150 | 550 | 230 |

| 18 | FXBW-110/100 | 110 | 100 | 16 | 1440±15 | 1200 | 3750 | 650 | 260 |

| 19 | FXBW-110/100 | 110 | 100 | 16 | 1325±15 | 1100 | 3490 | 600 | 250 |

| 20 | FXBW1-220/100 | 220 | 100 | 16 | 2150±30 | 1900 | 5040 | 1000 | 395 |

| 21 | FXBW2-220/100 | 220 | 100 | 16 | 2240±30 | 1900 | 5040 | 1000 | 395 |

| 22 | FXBW3-220/100 | 220 | 100 | 16 | 2150±30 | 1900 | 6300 | 1000 | 395 |

| 23 | FXBW4-220/100 | 220 | 100 | 16 | 2240±30 | 1900 | 6300 | 1000 | 395 |

| 24 | FXBW-220/100 | 220 | 100 | 16 | 2470±30 | 2250 | 7300 | 1150 | 450 |

| 25 | FXBW-220/100 | 220 | 100 | 16 | 2160±30 | 2000 | 6490 | 1050 | 410 |

| 26 | FXBW-220/100 | 220 | 100 | 16 | 2250±30 | 2060 | 6760 | 1050 | 410 |

| 27 | FXBW-220/100 | 220 | 100 | 16 | 2308±30 | 2060 | 6760 | 1050 | 410 |

| 28 | FXBW1-220/160 | 220 | 160 | 20 | 2150±30 | 1900 | 5040 | 1000 | 395 |

| 29 | FXBW2-220/160 | 220 | 160 | 20 | 2240±30 | 1900 | 5040 | 1000 | 395 |

| 30 | FXBW3-220/160 | 220 | 160 | 20 | 2150±30 | 1900 | 6300 | 1000 | 395 |

| 31 | FXBW4-220/160 | 220 | 160 | 20 | 2240±30 | 1900 | 6300 | 1000 | 395 |

Links:https://globefindpro.com/products/77798.html

-

Fuse Cutout (10-36kV)

Fuse Cutout (10-36kV)

-

Bypass Disconnect Switch

Bypass Disconnect Switch

-

YWM-16N Automatic Self-Feeding Plate Beveling Machine

YWM-16N Automatic Self-Feeding Plate Beveling Machine

-

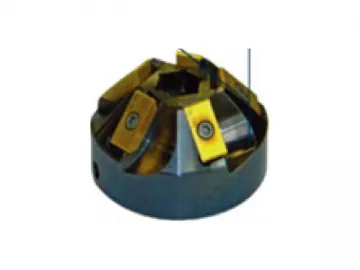

Tool Bits for ID Mount Pipe Beveller

Tool Bits for ID Mount Pipe Beveller

-

Tool Bits for Portable Beveller

Tool Bits for Portable Beveller

-

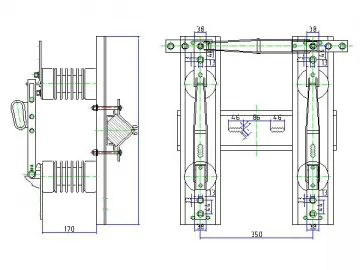

High Voltage Disconnect Switch (Three Phases)

High Voltage Disconnect Switch (Three Phases)

-

OD Mount Pipe Cutting & Beveling Machine with Light Alloy Body

OD Mount Pipe Cutting & Beveling Machine with Light Alloy Body

-

SF6 Insulated Ring Main Unit

SF6 Insulated Ring Main Unit

-

Post Insulator

Post Insulator

-

Plate Beveling Machine, GF-2046

Plate Beveling Machine, GF-2046

-

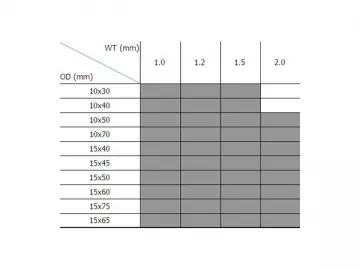

Rectangular Stainless Steel Tube

Rectangular Stainless Steel Tube

-

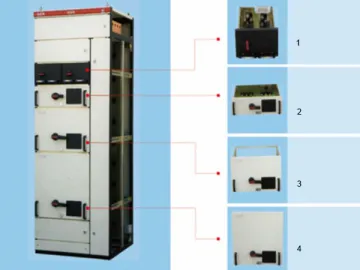

Low Voltage Switchgear (Withdrawable Type, Single Row)

Low Voltage Switchgear (Withdrawable Type, Single Row)