YWM-16N Automatic Self-Feeding Plate Beveling Machine

YWM-16N Automatic Self-Feeding Plate Beveling Machine

Product Descriptions

As with theYWM-12N model, the YWM-16N automatic self-feeding plate beveling machine canalso be used for plate edge prep beveling. Based onneeded bevel angle, it mainly implements plate edge beveling by using rollingcut method, so as to obtain qualified weld ready surface.

This plate edge bevelleris suitable for machining general structural steel, cast iron, rigid plastic,nonferrous metal, etc. Itis a kind of dedicated equipment for plate edge preparation. Thanks to thisplate processing equipment, such shortcomings as irregular bevel angle, roughbevel surface, too much noise resulted from flame cutting and grinding havebeen solved.

The self feeding plate beveling machine can travel along the edge of platesautomatically. In addition, it boasts precise bevel angle, convenient bevelangle adjustment, easy operation, high efficiency in unit time, environmentfriendliness, especial applicability to carbon steel machining, etc.

The self-propelled plate beveling machine canmake bevels 16mm wide bytraveling along the edge of the plates once. These steel plates feature wallthickness less than 45mmand tensile strength of 40kg/mm².If required, it also can make bevels 18mm wide by several times of processing. In addition,any bevel angle can be achieved within the range of 25° to 45°.

This type of plate edge beveling machine is a hot selling model with thehighest cost performance and the best overall performance, which can meet about80% actual demand of customers

Features

1. The plate machining equipment bevels plate by means of rolling cut.

2. It comes with higher efficiency and greater stability in that it isoutfitted with high quality speed reducer.

3. Self feeding without shock can accelerate beveling.

4. The angle of bevel and plate thickness is adjustable.

5. The plate beveling machine adopts cold working to prevent the bevel surfacefrom being oxidized.

6. It is appropriate for medium and thick plates machining.

| Technical Parameters | |

| Motor power | 2.2kw |

| Motor voltage | 380v |

| Rotating speed | 1450r/min |

| Net weight | 185kg |

| Max. bevel width | 16 mm |

| Bevel angle | 25-45° |

| Beveling speed | 1.5-2m/min |

| Plate thickness | >70 mm |

Links:https://globefindpro.com/products/77801.html

-

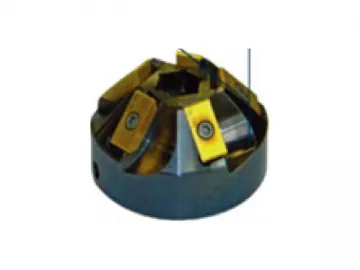

Tool Bits for ID Mount Pipe Beveller

Tool Bits for ID Mount Pipe Beveller

-

Tool Bits for Portable Beveller

Tool Bits for Portable Beveller

-

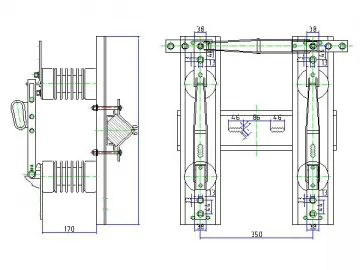

High Voltage Disconnect Switch (Three Phases)

High Voltage Disconnect Switch (Three Phases)

-

Square Slotted Stainless Steel Tube

Square Slotted Stainless Steel Tube

-

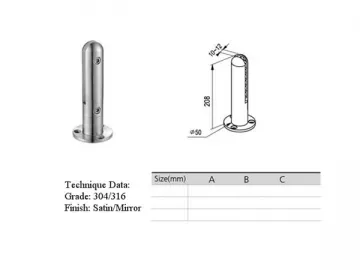

Stainless Steel Spigot

Stainless Steel Spigot

-

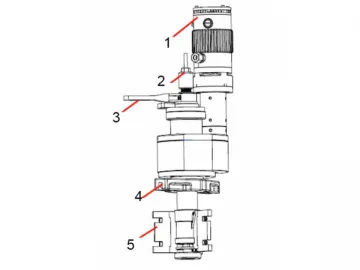

ID Mount Pneumatic/Electric Pipe Beveling Machine

ID Mount Pneumatic/Electric Pipe Beveling Machine

-

Bypass Disconnect Switch

Bypass Disconnect Switch

-

Fuse Cutout (10-36kV)

Fuse Cutout (10-36kV)

-

Suspension Insulator

Suspension Insulator

-

OD Mount Pipe Cutting & Beveling Machine with Light Alloy Body

OD Mount Pipe Cutting & Beveling Machine with Light Alloy Body

-

SF6 Insulated Ring Main Unit

SF6 Insulated Ring Main Unit

-

Post Insulator

Post Insulator