10kV, 35kV Insulated Overhead Cable

Standards

This 10kV insulated overhead cable strictly conforms to GB/T14049-2008 standard, namely aerial insulated cables with rated voltages of 10kV and 35kV. The 35kV type is produced according to the enterprise standard.

Working Conditions

1. The rated voltage is 10kV or 35kV.

2. The maximum operating temperature for conductor depends on the maximum working temperature of insulation, and the specific values for XLPE insulated type and HDPE insulated type are 90℃ and 75℃, respectively.

3. The maximum cable temperatures when short circuit occurs are 250℃ for XLPE insulated type, and 150℃ for HDPE insulated type. Meanwhile, the short circuit should not last for more than 5 seconds.

4. The ambient temperature when laying should not be lower than -20℃.

5. The bending radius should be bigger than the diameter of cylinder used in bending test.

Name Code

JK: Aerial cable

LH: Aluminum alloy

TR: Soft copper conductor

L: Aluminum

B: Natural color insulation

Q: Light and thin insulation

Type Descriptions

| Model | Product Name | Laying Attentions |

| JKYJ | Cu core XLPE insulated aerial cable | They fit for overhead fixed laying, and a certain distance between cables and trees should be taken into account. |

| JKTRYJ | Soft cu core XLPE insulated aerial cable | |

| JKLYJ | Al core XLPE insulated aerial cable | |

| JKLHYJ | Aluminum alloy core XLPE insulated aerial cable | |

| JKY | Cu core PE insulated aerial cable | |

| JKTRY | Soft cu core PE insulated aerial cable | |

| JKLY | Al core PE insulated aerial cable | |

| JKLHY | Aluminum alloy core PE insulated aerial cable | |

| JKLYJ/B | Al core natural color XLPE insulated aerial cable | |

| JKLHYJ/B | Aluminum alloy core natural color XLPE insulated aerial cable | |

| JKLYJ/Q | Al core light type XLPE insulated aerial cable | These products are suitable for overhead fixed laying, and a certain distance between cables and trees should be kept when designing cable stand. During working, the contact between cable and tree should be limited to a short time. |

| JKLHYJ/Q | Aluminum alloy core light type XLPE insulated aerial cable | |

| JKLY/Q | Al core light type PE insulated aerial cable | |

| JKLHY/Q | Aluminum alloy core light type PE insulated aerial cable |

Specifications

| Model | Core Number | Nominal Cross Section (mm2) | |

| 10kV | 35kV | ||

| JKYJ JKTRYJ JKLYJ JKLHYJ | 1 | 10-300 | 50-300 |

| 3 | 25-300 | ||

| 3 K(A) or 3 K(B) | 25-300 | ||

| K: 25-120 | |||

| JKY JKTRY JKLY JKLHY JKLYJ/Q JKLHYJ/Q JKLY/Q JKLHY/Q | 1 | 10-300 | |

| JKLYJ/B JKLHYJ/B | 3 | 25-300 | |

| 3 K(A) or 3 K(B) | 25-300 | ||

| K: 25-120 | |||

Note:

1. K stands for load carrying stranded conductor, and any specified section in the table above can be selected to match with relevant conductor based on the requirements of engineering design. If the span of pole is so big that extra bearing wire is needed, this wire is not included in the cable structure.

2. A represents steel load carrying stranded wire, and B is aluminum alloy load carrying stranded wire.

Technical Parameters of Conductor

| Nominal Section (mm2) | Resistance at 20℃ (≤Ω/km) | Breaking Strength (≥N) | |||||

| Hard Cu Core | Soft Cu Core | Al Core | Aluminum Alloy Core | Hard Cu Core | Al Core | Aluminum Alloy Core | |

| 10 16 25 35 50 70 95 120 150 185 240 300 400 | 0.749 0.540 0.399 0.276 0.199 0.158 0.128 0.1021 0.0777 0.0619 0.0484 | 1.830 1.150 0.727 0.524 0.387 0.268 0.268 0.153 | 3.080 1.910 1.200 0.868 0.641 0.443 0.320 0.253 0.206 0.164 0.125 0.100 0.0778 | 1.393 1.007 0.744 0.514 0.371 0.294 0.239 0.190 0.145 0.11 6 0.0904 | 8465 11731 16502 23461 31759 39911 49505 61846 79832 99788 133040 | 3762 5177 7011 10354 13727 17339 21033 26732 34679 43349 55707 | 6284 8800 12569 17596 23880 30164 37706 46503 60329 75411 10548 |

Note: The light and thin insulated air cable is without inner semi-conducting shielding layer.

Technical Parameters of Load Carrying Stranded Wire| Cross Section (mm2) | Breaking Strength of Steel Type (≥N) | Breaking Strength of Aluminum Alloy Type (≥N) |

| 25 35 50 70 95 120 | 30000 42000 56550 81150 110150 | 6284 8800 12569 17596 23880 30164 |

Qualifications

| Item | Unit | Data | Test Method | |

| 10kV | 35kV | |||

| Resistance of Conductor at 20℃ | Ω/km | GB14049-1993 (see the table above) | GB3048.4 | |

| Insulation Resistivity (without external shield) | MΩ·km | ≥1500 (≥1000 for light type) | ≥4100 | GB3048.5 |

| AC Voltage Test (1minute) | kV | 18 (2 for light type) | 63 | GB3048.8 |

| Partial Discharge Test (with external shield) | pC | ≤20 | GB3048.12 | |

| Dimensions and Breaking Strength Test of Conductor | GB14049-1993 (see the table above) | GB4909.2 and GB2951.2 | ||

| Hot Set Test | % | ≤ 175 | ≤175 | GB2951.18 |

| Bending Test | mm | Single core: 20±5% (D d) Multi-core: 15±5% (D d) | 20±5% (D d) | GB2951.23 |

| Impulse Voltage Test | kV | 93.8 (75 for light type) | 250 | GB3048.8 |

| Tracking Resistant Test of Insulation (without external shield) | A | ≤0.5 | ≤0.5 | GB3048.7 |

| Mechanical Property Tests of Insulation before and after Aging | GB14049-1993 | GB14049-1993 | GB2951 | |

| Adhesive Strength (slip-off) Test of Insulation | N | ≥180 | ≥180 | GB14049-1993 |

| Weather-proof Test of Insulation (without external shield) | GB14049-1993 | |||

| Peeling Test of Semi-Conducting Layer (with external shield) | N | 8-40 | GB14049-1993 | |

| Rub-Resistant Test of Printed Mark | GB6995.3 | |||

Application

This insulated overhead cable is a new product applied to overhead power transmission line, and is also the preferred choice for building or upgrading power grid with rated voltage of 10kV or 35kV. Meanwhile, it can ensure the safety of power line, and the soft copper core type is suitable for downlead of transformer.

Requirements for Delivery

For this overhead cable, there should be continuous marks like model, specification, rated voltage, manufacturer name and other information which are clear and rub-resistant. The total delivery length, and length and quantity of short cable should be decided through consultation when signing the contract.

Related Names

Copper Core Aerial Cable Manufacturer | Medium Voltage Telecommunication System | Alloy Core Electrical Cable

Links:https://globefindpro.com/products/78325.html

-

Instrument Signal Cable for Instrument Circuit

Instrument Signal Cable for Instrument Circuit

-

Garden Light

Garden Light

-

Flame Retardant, Plastics Insulated, Soft Power Cable

Flame Retardant, Plastics Insulated, Soft Power Cable

-

XLPE Insulated (Low-Smoke Halogen-Free) Shipboard Power Cable

XLPE Insulated (Low-Smoke Halogen-Free) Shipboard Power Cable

-

LED Street Light

LED Street Light

-

1kV Insulated Aerial Cable

1kV Insulated Aerial Cable

-

XLPE Insulated Flame Retardant Shipboard Power Cable

XLPE Insulated Flame Retardant Shipboard Power Cable

-

HPS Street Light

HPS Street Light

-

Flat Lift Cables with Wire Rope

Flat Lift Cables with Wire Rope

-

Fire Resistant Shipboard Power Cable

Fire Resistant Shipboard Power Cable

-

High Bay Light

High Bay Light

-

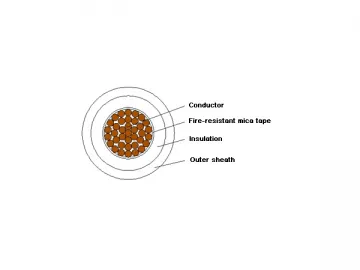

0.6/1kV Plastic Insulated Fire-Resistant Power Cable / Fire Performance Power Cable

0.6/1kV Plastic Insulated Fire-Resistant Power Cable / Fire Performance Power Cable