Roll Forming Machine

Our roll forming machine is specially designed in two types, and they are respectively capable of wall panel roll forming and corrugated panel roll forming.

Roll Former for Wall Panel

1. This roll former can be used to produce plug-in and hidden types of sandwich panel, ideal for refrigeration house construction.

2. Both ends of top and bottom steel sheets are processed in male and female joint shape, convenient for installation and splicing.

3. Cassette structure is adopted by this roll forming machine. Through regulating distance between wall panels, theoretical panel width is obtainable.

4. This sandwich panel machine is composed of top and bottom forming rollers which are demountable and interchangeable. The top rollers act passively and the bottom rollers are driven by motor via chain.

5. By adjusting distance between axles, interval between rollers can be regulated.

6. Working at a speed of 0-8m/min., this wall panel roll forming machine is available for stepless speed regulation, thus making the speed consistent with the speed of entire PU sandwich panel production line.

7. Uniformly electroplated with hard chrome, the service life of rollers is largely extended.

Roll Former for Corrugated Panel

1. This roll former comes with high-strength welded profile steel rack, working under motor power of 5.5KW.

2. Shape, quantity and size of corrugation can be tailored.

3. Through regulating thread rod of top bearing seat, interval between top and bottom rollers can be modulated.

4. This roof panel roll forming machine works at 0-8m/min. and the speed is adjustable in stepless way. Thus, the machine can be synchronized with entire production line.

5. After electroplated with hard chrome on surface, roller life is longer.

Links:https://globefindpro.com/products/78637.html

-

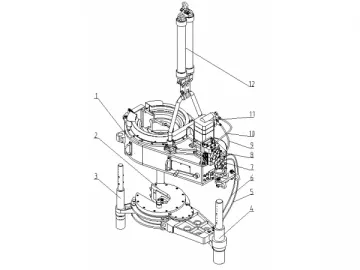

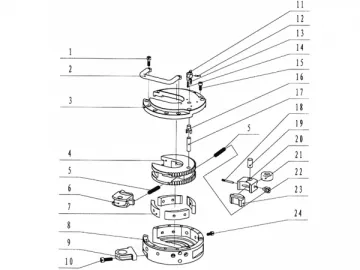

NJY/YT Computerized Torque Control System

NJY/YT Computerized Torque Control System

-

Cut-to-length Band Saw

Cut-to-length Band Saw

-

DQ197/40Y-TB Hydraulic Power Tongs

DQ197/40Y-TB Hydraulic Power Tongs

-

DQ197/40Y Hydraulic Power Tongs

DQ197/40Y Hydraulic Power Tongs

-

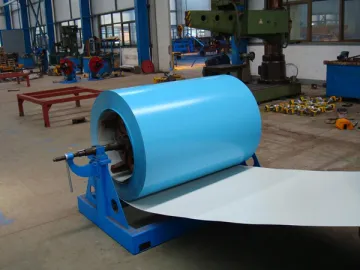

Uncoiler

Uncoiler

-

DQ178/40Y-TB Hydraulic Power Tongs

DQ178/40Y-TB Hydraulic Power Tongs

-

Uncoiler with Coil Feeding Car

Uncoiler with Coil Feeding Car

-

Hydraulic Power Pack

Hydraulic Power Pack

-

XQ28/1.8Y Sucker Rod Tongs

XQ28/1.8Y Sucker Rod Tongs

-

TQ340-35Y Casing Tongs

TQ340-35Y Casing Tongs

-

PU Foaming System

PU Foaming System

-

Laminating Machine

Laminating Machine