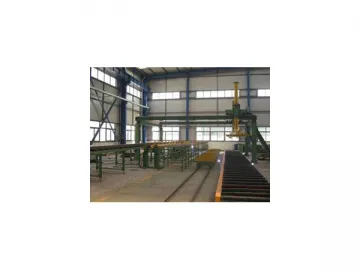

Laminating Machine

Structural Features

Our laminating machine is incorporated by top, bottom and internal roller stands, each of which is configured with pairs of rubber roller. The rollers mounted on top and internal stands are in flat design, and the rollers installed on bottom stand are in corrugated design. Meanwhile, the bottom stand is fixed, and the top stand is adjustable with regard to pressing height and force. The internal stand of our lamination machine can be regulated based on steel sheet shape.

When the laminating machine is used to produce flat panel, the internal roller stand height should be maximized to ensure that the rubber rollers of internal and bottom roller stands are in the same horizontal plane.

If the roll to roll laminator is applied for manufacturing corrugated panel, we should make sure that the internal stand height is lowered to the minimum. So, the rubber rollers mounted on the internal stand is 40mm lower than the rubber rollers installed on the bottom stand.

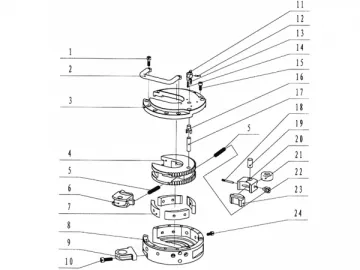

Meanwhile, our laminating machine is coupled with uncoiler and adopts clutch disc for braking, thus making sure that tension balance is remained. On the other hand, metering pump is utilized for glue feeding. Glue is first dripped on the lower steel plate by glue dripping hose and then is uniformly mixed by glue mixer. By contrast, uniformly mixed glue is directly coated on the top steel plate by glue spraying system.

Functional Features

1. This sandwich panel laminator is outfitted with several sets of electrical infrared ray heaters which provide proper heat for panel production under low temperature.

2. Scrap distributor re-distribute production cuttings via suction fan.

3. Our laminating machine is designed with a general electric box, button operated, and relay and contactor controlled. Thus, it is user and maintenance friendly.

4. Variable-frequency speed regulating technology is adopted, making for flexible speed regulation.

Links:https://globefindpro.com/products/78631.html

-

PU Foaming System

PU Foaming System

-

TQ340-35Y Casing Tongs

TQ340-35Y Casing Tongs

-

XQ28/1.8Y Sucker Rod Tongs

XQ28/1.8Y Sucker Rod Tongs

-

Hydraulic Power Pack

Hydraulic Power Pack

-

Uncoiler with Coil Feeding Car

Uncoiler with Coil Feeding Car

-

Roll Forming Machine

Roll Forming Machine

-

Caterpillar Laminating Machine

Caterpillar Laminating Machine

-

Cut-to-length Band Saw

Cut-to-length Band Saw

-

Caterpillar Laminating Machine

Caterpillar Laminating Machine

-

Stacker and Packing Machine

Stacker and Packing Machine

-

XQ89/3YC Hydraulic Power Tongs

XQ89/3YC Hydraulic Power Tongs

-

Rockwool (Mineral Wool), Glasswool Cutting and Feeding System

Rockwool (Mineral Wool), Glasswool Cutting and Feeding System