Press Brake CNC System

HT072

1. The hydraulic press brake CNC system, also known as CNC control panel, is able to position two motor-driven shafts precisely to perform accurate bending.

2. It supports manual, semi-automatic, automatic and continuously automatic mode.

3. In manual or semi-automatic mode, the activated shaft will move if the operator presses corresponding keys.

4. In automatic mode, the shaft moves automatically according to the programs stored in advance.

5. In semi-automatic mode, the sheet metal bending machine works in a single program cycle. The program is executed directly without storing.

E200

1. 240*128 LCD display screen

2. The operator can write multi-step programs at a time. The CNC system may automatically run programs and continuously carry out positioning.

3. The back gauge automatically draws back to avoid interfering with work pieces.

4. One-way positioning to eliminate transmission clearance between lead screws

5. Switch between metric system and imperial system

6. Position compensation

7. Power off memory function (optional)

8. Automatic search for reference point (optional)

DA41

1. High definition LCD display

2. Stop position control of sliding blocks

3. Back gauge control

4. Angle programming

5. Setting die parameters

6. Control over material selection

7. 100 programs

8. Every program contains 25 steps.

9. Panel-type installation

10. Servo control, frequency converting control and double speed AC control

DA52

1. Single-step programming

2. Navigation shortcut

3. 6.4’’ TFT LCD color display

4. Maximum 4 shafts control (Y1, Y2, X and V)

5. Workbench deflection compensation control

6. Die library, material library, product library

7. USB port

8. Its advanced Y shaft control algorithm can control both closed loop and open loop.

9. Panel-type installation, or suspension-type with a special box (optional)

DA56

1. Two-dimensional programming

2. The CNC system is equipped with a 10.4’’ TFT LCD color display.

3. Confirming bending steps

4. Calculating developed length

5. Workbench deformation compensation

6. USB port

7. Servo control, frequency converting control and AC motor control

DA65W

1. 2D graph programming

2. 3D graph display

3. 10.4’’TFT color display, 600MHz microprocessor

4. Standard Windows network components

5. Integrated personalized user operation panel

6. USB ports for keyboard and mouse

7. Supporting your specific application in the multitask environment

8. Port for angle correction sensor

DA69W

1. TFT color display screen

2. 3D graph

3. The CNC system supports automatically bending workpieces.

4. PLC function

5. Operation warning system

6. Prompt Message for Errors and Help Text

The system will prompt you if you program incorrectly, operate the hydraulic press brake improperly or the machine breaks down, so as to save time for troubleshooting.

7. Its real time Windows system is able to perform multitasking and document management.

8. The standard Ethernet interface allows Windows network connection.

9. It contains USB ports to connect to external devices, such as a keyboard or a mouse.

Links:https://globefindpro.com/products/79149.html

-

CNC Tandem Press Brakes

CNC Tandem Press Brakes

-

Articut CNC Wood Engraving Machine

Articut CNC Wood Engraving Machine

-

Allegretto Engraving Machine

Allegretto Engraving Machine

-

VMK-4016 Key Cutting Machine

VMK-4016 Key Cutting Machine

-

HD-418 Key Cutting Machine

HD-418 Key Cutting Machine

-

VRK-1080 Key Cutting Machine

VRK-1080 Key Cutting Machine

-

Rapicut Plasma Cutting Machine

Rapicut Plasma Cutting Machine

-

SE1010 Mold Engraving Machine

SE1010 Mold Engraving Machine

-

UV Flatbed Printer

UV Flatbed Printer

-

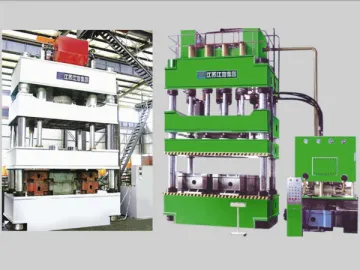

4 Column Double-Action Press

4 Column Double-Action Press

-

Avant Garde Engraving Machine

Avant Garde Engraving Machine

-

Heavy-duty Swing Beam Shear

Heavy-duty Swing Beam Shear