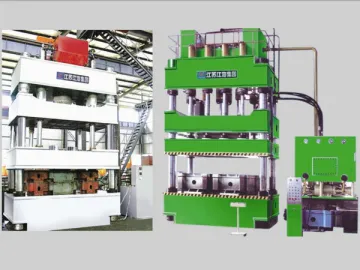

4 Column Double-Action Press

Equipped with four columns, the double-action press is designed to draw, bend, shape, blank or flange sheet metal. This hydraulic press is perfect for processing automobile parts, home appliances, kitchen utensils, tractors, motorcycles and so forth.

Optional Accessories for 4 Column Double-Action Press

Movable workbench, buffer device for blanking, photo-electric safety device, oil cooling device, displacement sensor, industrial touch screen, hydraulic or mechanical material smashing device, die clamping mechanism, die protection device, imported PLC

Main Features of 4-Column Double-Action Press

1. The double-action press follows a computer optimization design, which simplifies the structure and improves price-performance ratio.

2. On the basis of the welded-steel plate construction, the 4 column press does well in high accuracy and eccentric loading resistance.

3. Fitted with a cartridge valve, the hydraulic control system is proud of good reliability, long working life and small hydraulic shock. It has reduced connecting pipelines and leakage points.

4. Controlled by an imported PLC, its electrical system comes with compact structure, high sensitivity, reliable operation and easy maintenance. There are hydraulic cushions in the floor beam. Through an operation panel, the operator can choose operating cycle modes, namely blank pressing with ejection, blank pressing without ejection, and blank pressing with hydraulic cushion.

5. Operating mode of hydraulic press: Adjusting, manual, semi-automatic

6. Forming process specification: Stroke setting and pressure setting

Technical Parameters

| No. | Item | Unit | Model | |||

| YJH28-40/63 | YJH28-63/100 | YJH28-200/300 | ||||

| 1 | Nominal force | KN | 630 | 1000 | 3000 | |

| 2 | Drawing force | KN | 400 | 630 | 2000 | |

| 3 | Pressure | mm | 300 | 400 | 1000 | |

| 4 | Ejecting force | Mpa | 190 | 190 | 400 | |

| 5 | Maximum working pressure of liquid | mm | 25 | 25 | 25 | |

| 6 | Drawing sliding block stroke | mm | 500 | 600 | 700 | |

| 7 | Blank holder slide stroke | mm | 300 | 300 | 400 | |

| 8 | Dimension of drawing sliding block | From left to right | mm | 560 | 720 | 1000 |

| From front to back | mm | 500 | 580 | 900 | ||

| 9 | Dimension of blank holder slide | From left to right | mm | 560 | 720 | 1000 |

| From front to back | mm | 500 | 580 | 900 | ||

| 10 | Workbench dimension | From left to right | mm | 560 | 720 | 1000 |

| From front to back | mm | 500 | 580 | 900 | ||

| 11 | Open height of drawing sliding block | mm | 1100 | 1100 | 1400 | |

| 12 | Open height of blank holder slide | mm | 700 | 700 | 900 | |

| 13 | Drawing sliding block speed | Moving up and down with empty load | mm/s | 160 | 120 | 100 |

| Working | mm/s | 20-25 | 10-14 | 10-15 | ||

| Return stroke | mm/s | 100 | 120 | 80 | ||

| 14 | Product dimension | From left to right | mm | 2500 | 4000 | 4000 |

| From front to back | mm | 1500 | 2000 | 2000 | ||

| Height | mm | 3200 | 4100 | 4400 | ||

| 15 | Motor power | KW | 7.5 | 7.5 | ≈22 | |

| No. | Item | Unit | Model | |||

| YJH28-315/400 | YJH28-500/800 | YJH28-400/630 | ||||

| 1 | Nominal force | KN | 4000 | 8000 | 6300 | |

| 2 | Drawing force | KN | 3150 | 5000 | 4000 | |

| 3 | Pressure | mm | 800 | 3000 | 2300 | |

| 4 | Ejecting force | Mpa | 630 | 1000 | 1000 | |

| 5 | Maximum working pressure of liquid | mm | 25 | 25 | 25 | |

| 6 | Drawing sliding block stroke | mm | 800 | 1000 | 800 | |

| 7 | Blank holder slide stroke | mm | 400 | 1000 | 800 | |

| 8 | Dimension of drawing sliding block | From left to right | mm | 1260 | 3000 | 1400 |

| From front to back | mm | 1200 | 2200 | |||

| 9 | Dimension of blank holder slide | From left to right | mm | 1260 | 3000 | 1400 |

| From front to back | mm | 1260 | 2200 | 1400 | ||

| 10 | Workbench dimension | From left to right | mm | 1260 | 3000 | 1400 |

| From front to back | mm | 1200 | 2200 | 1400 | ||

| 11 | Open height of drawing sliding block | mm | 1500 | 1800 | 1700 | |

| 12 | Open height of blank holder slide | mm | 1000 | 1800 | 1150 | |

| 13 | Drawing sliding block speed | Moving up and down with empty load | mm/s | 100 | 100 | 100 |

| Working | mm/s | 8-12 | 10-15 | 15-20 | ||

| Return stroke | mm/s | 60 | 70 | 100 | ||

| 14 | Product dimension | From left to right | mm | 4500 | 5800 | 5600 |

| From front to back | mm | 2800 | 3000 | 3000 | ||

| Height | mm | 4600 | 6400 | 5500 | ||

| 15 | Motor power | KW | ≈22 | ≈44 | ≈44 | |

| No. | Item | Unit | Model | |||

| YJH28-630/1030 | YJH28-1200/2000 | YJH28-2000/2600 | ||||

| 1 | Nominal force | KN | 10300 | 20000 | 26000 | |

| 2 | Drawing force | KN | 6300 | 12000 | 20000 | |

| 3 | Pressure | mm | 4000 | 8000 | 6000 | |

| 4 | Ejecting force | Mpa | 2000 | 4000 | 1000 | |

| 5 | Maximum working pressure of liquid | mm | 25 | 25 | 25 | |

| 6 | Drawing sliding block stroke | mm | 1300 | 1350 | 2000 | |

| 7 | Blank holder slide stroke | mm | 1300 | 1350 | 2000 | |

| 8 | Dimension of drawing sliding block | From left to right | mm | 1900 | 2000 | 2000 |

| From front to back | mm | 1500 | 1950 | 1800 | ||

| 9 | Dimension of blank holder slide | From left to right | mm | 2600 | 3000 | 3500 |

| From front to back | mm | 2200 | 2500 | 3500 | ||

| 10 | Workbench dimension | From left to right | mm | 2600 | 3000 | 3500 |

| From front to back | mm | 2200 | 2500 | 3500 | ||

| 11 | Open height of drawing sliding block | mm | 2000 | 2600 | 4500 | |

| 12 | Open height of blank holder slide | mm | 2000 | 2400 | 4500 | |

| 13 | Drawing sliding block speed | Moving up and down with empty load | mm/s | 100 | 100 | 100 |

| Working | mm/s | 15-20 | 12-18 | 10-16 | ||

| Return stroke | mm/s | 80 | 80 | 80 | ||

| 14 | Product dimension | From left to right | mm | 5700 | 7000 | 8000 |

| From front to back | mm | 2800 | 2800 | 3800 | ||

| Height | mm | 7400 | 9500 | 8800 | ||

| 15 | Motor power | KW | ≈60 | ≈154 | ≈154 | |

Note: Because our research and development team is continuously improving products, if sample data differ from actual product data, the parameters will comply with the technical agreement without notice.

window.onload =function(){setItemByDivId('container','one|two|three|four|five|six|seven|eight','etw_link','color:#fff; background:#1d4ca6;','color:#fff;background:#4a4a4a','setclass')}

Links:https://globefindpro.com/products/79145.html

-

UV Flatbed Printer

UV Flatbed Printer

-

SE1010 Mold Engraving Machine

SE1010 Mold Engraving Machine

-

Rapicut Plasma Cutting Machine

Rapicut Plasma Cutting Machine

-

Press Brake CNC System

Press Brake CNC System

-

CNC Tandem Press Brakes

CNC Tandem Press Brakes

-

Articut CNC Wood Engraving Machine

Articut CNC Wood Engraving Machine

-

Avant Garde Engraving Machine

Avant Garde Engraving Machine

-

Heavy-duty Swing Beam Shear

Heavy-duty Swing Beam Shear

-

Fiber Laser Cutting Machine

Fiber Laser Cutting Machine

-

4 Axis CNC Cutting Machine

4 Axis CNC Cutting Machine

-

Four Column Press

Four Column Press

-

Camaro Engraving Machine

Camaro Engraving Machine