Avant Garde Engraving Machine

AP-1212Y

AP-1318Y

AP-1325Y

AP-1530Y

The Avant Garde engraving machine is a new kind of CNC carving equipment that is aimed at mid-range market, and it is primarily applied to engrave signage, wood furniture, industrial prototype, printed circuit board, work-holding device and so on.

Advantages

1. When it comes to an engraver, conventional ball screw drive exhibits high positioning accuracy (up to ±0.02mm), while rack and pinion drive is characterized by fast moving speed (up to 7.2m/min). However, this engraving machine perfectly combines these two advantages together to make itself work smoothly and accurately, thus accomplishing engraving or cutting jobs as required.

2. For this CNC cutting machinery, the applied new generation high-speed digital signal controller (DSC) greatly quickens data processing speed, while both linear motion and arc motion can be conducted in a smooth way.

3. The control system provides operators with different working modes, such as oblique cutting mode, memory cutting mode (after power outage), constant surface speed mode, arbitrary cutting sequence mode, planar engraving mode, relief engraving mode, expert mode, etc. As a result, operators could select the best working mode according to specific application, and the extremely convenient operation eliminates the risk of operating problems which are very likely to occur if the operation procedures are quite complicated.

4. Aside from abovementioned working modes, there is a user defined mode which allows users to set different groups of processing parameters based on their working experience, and these data are stored in this mechanical engraving machine. When necessary, users can access these memorized cutting sequences to ease machining operations.

5. This engraving machine also realizes several advanced machining functions including matrix processing, symmetrical machining, scan processing, hole drilling and others, thereby meeting the requirements of some special treatments.

6. Due to the implementation of our self-developed CNC control system and wireless handheld controller, users will find it is very convenient to manipulate this industrial engraving equipment. Additionally, the control system is outfitted with a color screen.

7. Every authorized client could directly download upgrade programs on our official website to promote machining performances.

Technical Data

| Model | Unit | AP-6590Y | AP-1212Y | AP-1318Y | AP-1325Y | AP-1530Y |

| Positioning accuracy | mm | ±0.02 | ±0.02 | ±0.03 | ±0.05 | ±0.05 |

| Variable frequency main spindle motor | W | 2200 | 2200 | 2200 | 3700 | 3700 |

| Max. main spindle speed | rpm | 24000 | 24000 | 24000 | 18000 | 18000 |

| Cutting tool diameter | mm | Ф3.175/6 | Ф3.175/6 | Ф3.175/4/6/8 | Ф3.175/4/6/8/12.7 | Ф3.175/4/6/8/12.7 |

| Max. moving speed | m/min | 7.2/25 | 7.2/25 | 7.2/25 | 25 | 25 |

| Table size | mm | 720×1390 | 1360×1730 | 1360×2330 | 1360×3230 | 1600×3730 |

| Max. stroke | mm | 650×900×110 | 1200×1200×110 | 1300×1800×110 | 1300×2500×110 | 1500×3000×110 |

| Total size | mm | 1750×1270× 1460 | 2100×1910× 1460 | 2700×1910× 1460 | 1890×3500× 1460 | 2130×4000× 1460 |

| Power supply | V/Hz | AC 220±10%/50 | AC 220±10%/50 | AC 220±10%/50 | AC 220±10%/50 | AC 220±10%/50 |

| Total power | kW | 2.5 | 3 | 3 | 4.5 | 4.5 |

| Weight | kg | 430 | 660 | 780 | 1080 | 1250 |

| Note:1. A 500W floating main spindle and a WL-901 wireless remote controller are optional for all of these engraving machines.2. The technical data are subject to change without prior notice, and they are in accordance with our technical standard. | ||||||

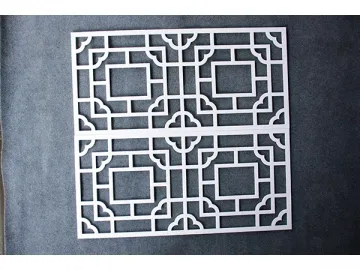

Processing Samples

Links:https://globefindpro.com/products/79144.html

-

4 Column Double-Action Press

4 Column Double-Action Press

-

UV Flatbed Printer

UV Flatbed Printer

-

SE1010 Mold Engraving Machine

SE1010 Mold Engraving Machine

-

Rapicut Plasma Cutting Machine

Rapicut Plasma Cutting Machine

-

Press Brake CNC System

Press Brake CNC System

-

CNC Tandem Press Brakes

CNC Tandem Press Brakes

-

Heavy-duty Swing Beam Shear

Heavy-duty Swing Beam Shear

-

Fiber Laser Cutting Machine

Fiber Laser Cutting Machine

-

4 Axis CNC Cutting Machine

4 Axis CNC Cutting Machine

-

Four Column Press

Four Column Press

-

Camaro Engraving Machine

Camaro Engraving Machine

-

CNC Electro-hydraulic Press Brake

CNC Electro-hydraulic Press Brake