Fiber Laser Cutting Machine

As revealed by its self-explanatory name, a fiber laser cutting machine uses a fiber laser as the laser source to provide laser beam which is then focused on the surface of material to be cut. After cutting, the material surface is extremely smooth, making this laser cutting center widely adopted in the manufacturing process of elevators, leaf springs, electric parts, advertising signs, kitchen wares, automotive components, mechanical parts of textile machinery, high- or low-voltage electrical cabinets and more.

Features

1. The fiber laser cutting machine has a small footprint, and the worktable is movable.

2. The fiber laser exhibits a high photoelectric conversion efficiency which is typically over 30%, and cooling water system is not required because air cooling has been proven to be effective enough. Accordingly, electricity is saved to a large extent, thereby reducing the operating cost as well as enhancing the overall productivity. In addition, the key parts of fiber laser are able to work normally for tens of thousands of hours.

3. Our fiber laser cutting machine only consumes electricity when generating laser beams, indicating that extra gas is not necessary. As a result, the operating cost and maintenance cost are both cut down.

4. The fiber laser machine adopts modular redundancy design, and there is no optical lens inside the resonant cavity. Hence, start time is not needed, and this highly stable machine also avoids the necessity of adjustment and maintenance. These properties make our fiber laser system distinct from conventional laser cutting machines.

5. For our fiber laser, its laser wavelength is only 1.064 microns, which is only ten percent of that of CO2 lasers. The shorter wavelength improves beam quality and power density which are very important to enhance beam absorption in the material to be cut, thereby offering superior cutting and welding performance. In this way, the operating cost is lowered.

6. If fitted with an optical shutter, the laser beam could be split into several channels, allowing simultaneous working of different devices. From this point of view, our fiber laser cutting machine realizes simple integration with more machines.

Technical Data

| Model | FL-1530Y | Unit |

| Cutting range | 1500×3000 | mm |

| Cutting precision | ±0.05 | mm |

| Positioning accuracy | ±0.05 | mm |

| External size | 4570×2780×1900 | mm |

| Max. laser power | 400 | W |

| Max. material thickness | 6mm for carbon steel, 3mm for stainless steel | |

| Applicable material | Carbon steel, stainless steel, copper, aluminum | |

| Total power | 5 | kW |

| Total weight | 1800 | kg |

| Power | 3 | kW |

| Weight | 110 | kg |

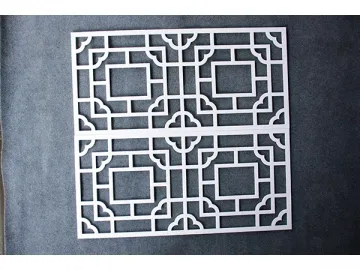

Processing Samples

Links:https://globefindpro.com/products/79142.html

-

Heavy-duty Swing Beam Shear

Heavy-duty Swing Beam Shear

-

Avant Garde Engraving Machine

Avant Garde Engraving Machine

-

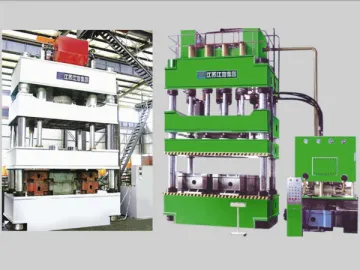

4 Column Double-Action Press

4 Column Double-Action Press

-

UV Flatbed Printer

UV Flatbed Printer

-

SE1010 Mold Engraving Machine

SE1010 Mold Engraving Machine

-

Rapicut Plasma Cutting Machine

Rapicut Plasma Cutting Machine

-

4 Axis CNC Cutting Machine

4 Axis CNC Cutting Machine

-

Four Column Press

Four Column Press

-

Camaro Engraving Machine

Camaro Engraving Machine

-

CNC Electro-hydraulic Press Brake

CNC Electro-hydraulic Press Brake

-

Diva Engraving Machine

Diva Engraving Machine

-

Double-Row Tapered Roller Bearings

Double-Row Tapered Roller Bearings