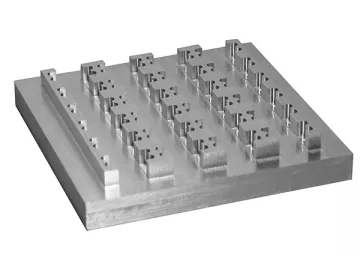

VMK-0808 Key Cutting Machine

The VMK-0808 key cutting machine fits for making tumbler holes, internal and external tooth, wavy groove, hole-groove combination, slot combination as well as lock cylinder. The CAD designed compact structure allows fully use of the space in a lockset factory, and the corresponding production line can be set up easily.

Features

1. Our CNC key making machine has an embedded 32-bit RISC microprocessor, so the control system possesses higher data processing speed. Accordingly, much higher production efficiency is achieved.

2. There are two motorized spindles whose rotation speed could reach up to as high as 24000rpm, and stepless VFD technology is also adopted. Thus, finished keys have smooth surface and dimensional accuracy. In addition, lower noise level is also obtained.

3. Thanks to the built-in program, on-site programming is very convenient, and machining process can be carried out step by step rather than as a whole. Moreover, pneumatic clamping device and foot switch help users out from complicated operation, and this key cutting machine would output 5000 pieces of common 6-pin keys at least. Additionally, the software and clamping device could be changed to fit for other applications.

4. With our online coding system, one engraving machine could engrave corresponding code number while producing keys. Moreover, our cutting machine uses photoelectric barcode scanner to recognize barcode, and then processes keys.

Technical Data

| Positioning accuracy | ±0.03 | mm |

| Variable frequency main spindle motor | 800×2 | W |

| Max. main spindle speed | 24000 | rpm |

| Cutting tool diameter | Ф3.175/4/6 | mm |

| Max. moving speed | 4 | m/min |

| Table size | 155×155 | mm |

| Max. stroke | 100×100×80 | mm |

| Overall dimensions | 800×600×1350 | mm |

| Power supply | AC 220±10%/50 | V/Hz |

| Power consumption | 2 | kW |

| Weight | 125 | kg |

Links:https://globefindpro.com/products/79157.html

-

MEII-2212 Mold Engraving Machine

MEII-2212 Mold Engraving Machine

-

Single Action Press

Single Action Press

-

Precicut Plasma Cutting Machine

Precicut Plasma Cutting Machine

-

SE3230 Mold Engraving Machine

SE3230 Mold Engraving Machine

-

Heavy Duty Mechanical Shear

Heavy Duty Mechanical Shear

-

MEII-4242 Mold Engraving Machine

MEII-4242 Mold Engraving Machine

-

VMK-3230 Key Cutting Machine

VMK-3230 Key Cutting Machine

-

VRK-1080 Key Cutting Machine

VRK-1080 Key Cutting Machine

-

HD-418 Key Cutting Machine

HD-418 Key Cutting Machine

-

VMK-4016 Key Cutting Machine

VMK-4016 Key Cutting Machine

-

Allegretto Engraving Machine

Allegretto Engraving Machine

-

Articut CNC Wood Engraving Machine

Articut CNC Wood Engraving Machine