MH-3860 HBCD-free Flame Retardant Masterbatch for XPS

The MH-3860 HBCD-free flame retardant masterbatch for XPS is a chemical additive basically used in extruded polystyrene boards. In comparison with traditional HBCD masterbatch, this product mainly contains eco-friendly Br-P polymeric flame retardant. It adopts PS as a carrier, accompanied with various auxiliaries such as the flame retardant synergist, small molecule scavenger, and the macromolecular chain extender. As a fire retardant, our product performs better than HBCD. Its advantages are listed as follows.

1. Ultra Strong Resistance to High Temperature

Decomposition temperature of the main content of our product is actually higher than 240 degrees Celsius, for guarantee the optimum mixing temperature during polystyrene molding process. Also, our HBCD-free flame retardant masterbatch can protect screws from being corroded.

2. Superb Smoke-Suppression Effect

Addition of small molecule scavenger can significantly reduce the amount of smoke produced by extruded boards. It allows the smoke density of manufactured goods to be reduced by up to 30%.

3. Improved Flow Properties

The HBCD-free flame retardant masterbatch is added with flow modifier, which can enhance fluidity, and also allows yield to be increased by 20%.

4. Increased Melts Strength

Owing to the addition of macromolecular chain extender, both viscosity and strength of melts can be greatly improved, which results in increased compressive strength of boards. In addition, our HBCD-free flame retardant masterbatch can improve both expansion ratio and the bulk density of boards, so as to provide better mechanical properties.

Main Specifications

| Items | Unit | MH-3860 |

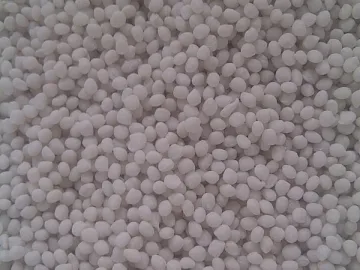

| Appearance | - | Spherical granules |

| Main Content | % | ≥70 |

| Moisture | ppm | ≤2000 |

| Density | g/cm3 | 1.4±0.2 |

| Applications | - | XPS |

| Recommended Dosage | % | 5-8 B13-5 B2 |

Suggestions

1. Considering the low melting point of its main content, our product had better be used with a double-screw XPS production equipment to lower the temperature of feed zone.

2. Please mix the HBCD-free flame retardant masterbatch with PS material uniformly to prevent the occurrence of current fluctuation.

Packing, Storage and Transportation

1. This product is wrapped in a paper-plastic compound bag lined with PE bag. Its net weight is 25kg/bag.

2. Our product is transported in accordance with the standard of general chemicals. It must be sealed and stored in a dry and cool place.

Links:https://globefindpro.com/products/79392.html

-

Two in One Carpet Extractor

Two in One Carpet Extractor

-

Sofa Cleaner

Sofa Cleaner

-

Pressure Washer with Hose

Pressure Washer with Hose

-

Low Noise Wet and Dry Vacuum Cleaner

Low Noise Wet and Dry Vacuum Cleaner

-

Telescopic Rod

Telescopic Rod

-

Straight Steel Floor Squeegee

Straight Steel Floor Squeegee

-

MH-2800 Flame Retardant Compound for PP Tube

MH-2800 Flame Retardant Compound for PP Tube

-

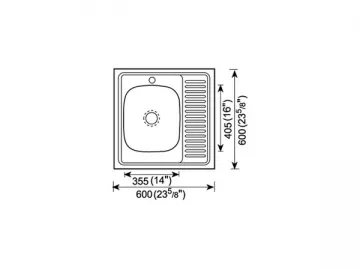

Single Bowl Single Drainer Sink

Single Bowl Single Drainer Sink

-

MH-9800 Red Phosphorus Flame Retardant Masterbatch

MH-9800 Red Phosphorus Flame Retardant Masterbatch

-

MH-1800 Flame Retardant Masterbatch for PE

MH-1800 Flame Retardant Masterbatch for PE

-

Long Handle Scraper

Long Handle Scraper

-

Short Handle Floor Brush

Short Handle Floor Brush