MH-1800 Flame Retardant Masterbatch for PE

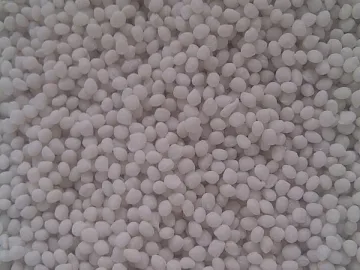

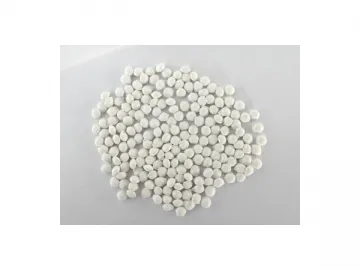

The MH-1800 flame retardant masterbatch for PE is made from a highly effective compound flame retardant with proprietary technology. It can offer reliable fire resistance, easy dispersion, and high compatibility with matrix resin. Other advantages include superb processing fluidity, extremely high thermal stability, and high light stability. The fire retarded masterbatches can achieve an excellent FR effect without adding antimony trioxide. It can be directly used in injection process after being mixed with PE materials.

The flame retardant masterbatch for PE is a good solution compared with traditional flame retardants that have numerous disadvantages such as high density, high cost, precipitation, blooming, whitening, poor compatibility with resins, and the serious deterioration of physical properties.

This fire retardant chemical is currently the best choice for PE retardant products. It is made in full compliance with EU environmental standards (RoHS). Our product does not contain polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE). It is mostly used in PE sheets, PE pipes, PE boards, wires, cables, and more.

Technical Index

| Items | Unit | MH-1801 | MH-1802 |

| Appearance | - | White Round Granule | White Round Granule |

| FR Content | % | ≥80 | ≥70 |

| Moisture | ppm | ≤3000 | ≤3000 |

| Density | g/cm3 | 1.9±0.2 | 1.7±0.2 |

| Application | - | PP Injection and Extrusion | PP Drawing and Blowing |

| Recommended Dose | % | 15-25 | 10-15 |

Packing and Storage

Our flame retardant masterbatch for PE is packed in a 25kg/bag paper-plastic compound outer and PE inner bag. This product must be handled with care during transportation. It should also keep air-tight and dry during storage.

Suggestion

1. In case of long-term storage, this product must be dried before use.

2. Customers need to know both properties and process conditions of all products before use, and then choose the optimum technical parameters for production.

3. The above-mentioned data is normal laboratory values for your information. Specific data is determined by practical service conditions and required flammability rating.

Links:https://globefindpro.com/products/79388.html

-

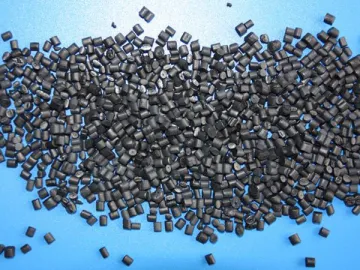

MH-9800 Red Phosphorus Flame Retardant Masterbatch

MH-9800 Red Phosphorus Flame Retardant Masterbatch

-

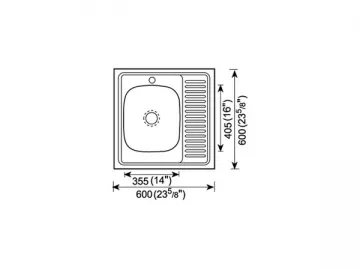

Single Bowl Single Drainer Sink

Single Bowl Single Drainer Sink

-

MH-2800 Flame Retardant Compound for PP Tube

MH-2800 Flame Retardant Compound for PP Tube

-

MH-3860 HBCD-free Flame Retardant Masterbatch for XPS

MH-3860 HBCD-free Flame Retardant Masterbatch for XPS

-

Two in One Carpet Extractor

Two in One Carpet Extractor

-

Sofa Cleaner

Sofa Cleaner

-

Long Handle Scraper

Long Handle Scraper

-

Short Handle Floor Brush

Short Handle Floor Brush

-

MH-6800 Brominated FR Masterbatch

MH-6800 Brominated FR Masterbatch

-

Plastic Sponge Squeegee

Plastic Sponge Squeegee

-

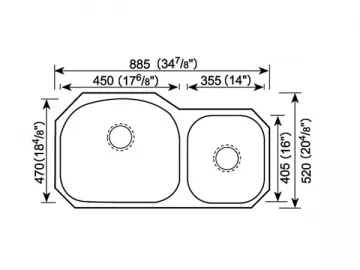

Undermount Double Bowl Sink

Undermount Double Bowl Sink

-

Triple Bowl Sink

Triple Bowl Sink