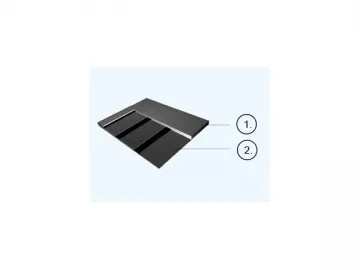

PVG/PVC Solid Woven Conveyor Belt

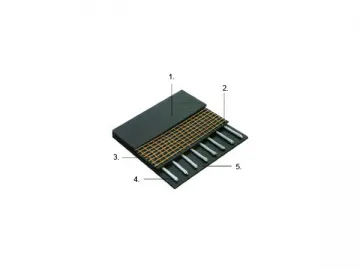

As the name implies, this range of solid woven conveyor belt uses solid woven as carcass which is then coated with PVC or PVG by dipping method. The PVC or PVG cover is designed to offer great antistatic and flame retardant properties.

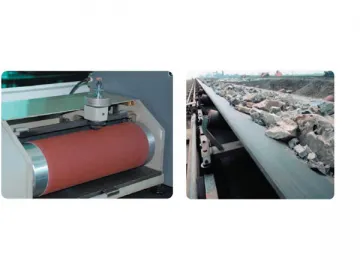

Due to the special structure design, our range of solid woven conveyor belt is not prone to delaminating and combustion. It is resistant to tearing, impact, and water erosion. That means, the solid woven belt is extremely suitable coal mines, shaft, and other flammable places. It is a great fire resistant conveyor belt for coal and chemicals conveying. The solid woven PVC conveyor belt is applicable for dry working conditions and tilt angle of below 16°. Differently, PVG conveyor belt can be applied to humid working environment.

Features

1. PVC Solid Woven Conveyor Belt

a. The tensile force and elongation can be balanced when the PVC belting gets into wheels.

b. It resists delaminating, impact, and tearing.

c. Its enclosed edges will not be abraded.

d. The joints can be clamp type or connected with hot glue. They are easy to maintain.

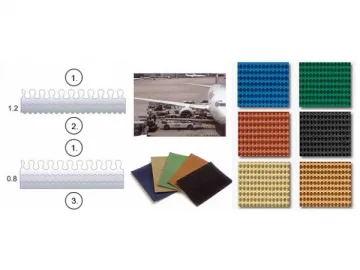

2. PVG Solid Woven Conveyor Belt

As compared with PVC Conveyor Belting, the PVG conveyor belt better resists wearing and has larger friction coefficient. Its slant conveying angle is 2°-6° larger.

Mechanical Property

The solid woven conveyor belt comes with excellent mechanical property. It can be used for a long time, and offers the cost-optimal installation and application.

Joint Property

Based on belt strength and core structure, the solid woven conveyor belt is available with different joints for option. When using mechanical buckles, the joint strength reaches 50% to 90% of belt strength. A vulcanized joint has the strength up to 60%-90% of belt strength. Anyway, various kinds of joints are available to ensure safety and high-efficient operation of conveying system.

Flame Retardant Property of PVG/PVC Solid Woven Conveyor Belt

1. Roller Friction: Roller surface temperature is no more than 325℃.

2. Combustion with Alcohol Blast Burner: With covering layer: average value≤3s; Without covering layer: average value≤5s;

3. Propane Combustion: nondestructive length is greater than 250mm.

4. The average surface resistance is 3.0×108Ω.

Main Technical Index of PVG/PVC Solid Woven Conveyor Belt

| Item | Combustion Alcohol Blast Burner | Roller Friction | Surface Resistance | Tunnel Propane Combustion |

| Index Value | With covering layer: average value≤3s; unit value: 10s | ≤325℃No Spark | ≤3×108Ω | ≥250mm |

| Without covering layer: average value≤5s; Unit value: 15s |

Specifications of PVG/PVC Solid Woven Conveyor Belt

| Model | Tensile Strength(N/mm) | Elongation at Break %≥ | Belt Width | Belt Length Per Coil | Reference Weight | |||

| In Warp | In Weft | In Warp | In Weft | mm | m | PVC | PVG | |

| 580S | 580 | 245 | 15 | 18 | 650-1400 | 200 | 11.2 | 16.8 |

| 680s | 680 | 265 | 12.0 | 17.1 | ||||

| 800s | 800 | 280 | 14.0 | 17.6 | ||||

| 1000s | 1000 | 300 | 15.5 | 19.6 | ||||

| 1250s | 1250 | 350 | 16.5 | 20.8 | ||||

| 1400s | 1400 | 350 | ||||||

| 1600s | 1600 | |||||||

| 1800s | 1800 | |||||||

| 2000s | 2000 | |||||||

| 2240s | 2240 | |||||||

| 2500s | 2500 | |||||||

Links:https://globefindpro.com/products/80401.html

-

CC Conveyor Belt

CC Conveyor Belt

-

VOLVO Revolving Wheel Nut (DX0046)

VOLVO Revolving Wheel Nut (DX0046)

-

Ripstop Steel Cord Conveyor Belt

Ripstop Steel Cord Conveyor Belt

-

Special Rubber Sheet

Special Rubber Sheet

-

Fire Resistant Steel Cord Conveyor Belt

Fire Resistant Steel Cord Conveyor Belt

-

Abrasion Resistant Conveyor Belt

Abrasion Resistant Conveyor Belt

-

Advanced Rubber Sheet

Advanced Rubber Sheet

-

Sidewall Conveyor Belt

Sidewall Conveyor Belt

-

Cold Resistant Conveyor Belt

Cold Resistant Conveyor Belt

-

Rough Top Conveyor Belt

Rough Top Conveyor Belt

-

SCANIA Front Wheel Bolt (DXE017)

SCANIA Front Wheel Bolt (DXE017)

-

Heat Resistant Conveyor Belt

Heat Resistant Conveyor Belt