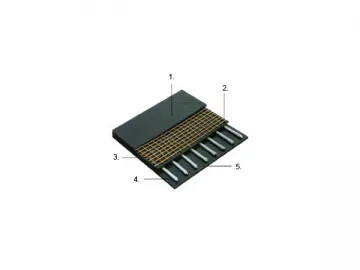

Ripstop Steel Cord Conveyor Belt

1.Upper Covering Layer

2.Core Rubber

3.Strengthened Layer

4.Wire Rope

5.Lower Covering Layer

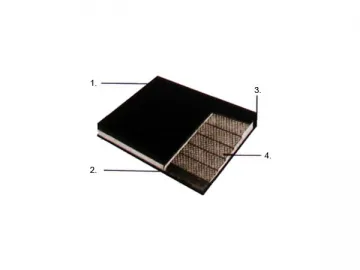

Introduction of Ripstop Steel Cord Conveyor Belt

On the basis of common steel core belt, the ripstop steel cord conveyor belt is added with one or two layers of anti-tearing mesh, for preventing foreign matters or tearing. Steel mesh and fabric mesh are optional. The steel one has the tearing strength of 125~800N/mm, while the fabric one comes with tearing strength of 50~80N/mm.

For enhanced strength, the ripstop conveyor belt uses galvanized steel wire as the carcass. The high strength rubber covers ensures great abrasion and aging resistance, which makes the product a better replacement of conventional abrasion resistant conveyor belt. Steel wire rope of open structure securely combines with rubber, as it has been zinc coated. For that reason, the steel cord conveyor belt can be used for a long time, and it won't be torn apart even if it has been impaled by sharp objects.

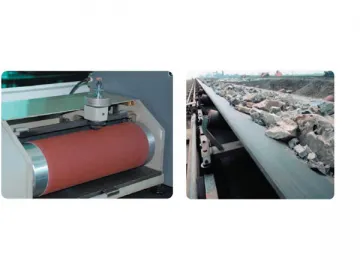

Application

This steel cord conveyor belt is applicable for mines, ports, power plants, metallurgy factories, construction materials factories, and many other industries. It is applied for long-distance, high speed materials conveying.

Specifications of Ripstop Steel Cord Conveyor Belt

Tensile Strength: 630N/mm-5400N/mm

Width: 800mm-2000mm

| Model | ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 | ST5400 | |||

| Longitudinal Tensile Strength(N/mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 | |||

| Maxi. Nominal Diameter of Steel Wire Rope (mm) | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 6.0 | 7.2 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 | |||

| Space Between Steel Wire Ropes (mm) | 10 ±1.5 | 10 ±1.5 | 12 ±1.5 | 12 ±1.5 | 12 ±1.5 | 12 ±1.5 | 15 ±1.5 | 15 ±1.5 | 15 ±1.5 | 15 ±1.5 | 16 ±1.5 | 17 ±1.5 | 17 ±1.5 | |||

| Thickness of Upper Covering Layer (mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 | |||

| Thickness of Lower Covering Layer (mm) | 5 | 5 | 6 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8.5 | 9 | |||

| Width (mm) | No. of Steel Wire Rope | |||||||||||||||

| ST 630 | ST 800 | ST 1000 | ST 1250 | ST 1600 | ST 2000 | ST 2500 | ST 3150 | ST 3500 | ST 4000 | ST 4500 | ST 5000 | ST 5400 | ||||

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | |||||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 59 | 55 | 55 | |||

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 76 | 77 | 77 | 71 | 66 | 66 | |||

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 89 | 90 | 90 | 84 | 78 | 78 | |||

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 104 | 104 | 96 | 90 | 90 | |||

| 1800 | 171 | 143 | 143 | 143 | 143 | 114 | 114 | 117 | 117 | 109 | 102 | 102 | ||||

| 2000 | 159 | 159 | 159 | 159 | 128 | 128 | 130 | 130 | 121 | 113 | 113 | |||||

| Remark: Covering layer thickness, steel wire rope diameter, and space between steel wire ropes can be tailor-made upon request. | ||||||||||||||||

Main Technical Index of Ripstop Steel Cord Conveyor Belt

1. Performance of Covering Rubber

| Item | Performance Index | |||

| H | D | L | ||

| Tensile Strength | Mpa ≥ | 24.0 | 18.0 | 15.0 |

| Elongation at Break | % ≥ | 450 | 400 | 350 |

| Abrasion | mm2≤ | 120 | 100 | 200 |

2. Bonding strength of steel wire rope conforms to rules specified by GB/T9770.

3. Bonding Strength between Layers: ≥10/N

4. Tear Resistance

| Item | Performance Index | |

| A | B | |

| Cracking Resistance, KN, ≥ | 3.0 | 10.0 |

| Impact Strength, NM, ≥ | 400.0 | 1000.0 |

In addition to steel cord reinforced rubber conveyor belts, we at Yiheng, as a dedicated manufacturer, can also design many other styles of industrial belts for conveyor systems. If you need any kind of conveyor belting for either packaged or bulk material handling purpose, please don't hesitate to contact us.

Links:https://globefindpro.com/products/80405.html

-

Special Rubber Sheet

Special Rubber Sheet

-

Fire Resistant Steel Cord Conveyor Belt

Fire Resistant Steel Cord Conveyor Belt

-

Abrasion Resistant Conveyor Belt

Abrasion Resistant Conveyor Belt

-

Mercedes-Benz Sonacome Rear Wheel Bolt (DXE008)

Mercedes-Benz Sonacome Rear Wheel Bolt (DXE008)

-

Oil Resistant Conveyor Belt

Oil Resistant Conveyor Belt

-

Standard Fire Resistant Conveyor Belt

Standard Fire Resistant Conveyor Belt

-

VOLVO Revolving Wheel Nut (DX0046)

VOLVO Revolving Wheel Nut (DX0046)

-

CC Conveyor Belt

CC Conveyor Belt

-

PVG/PVC Solid Woven Conveyor Belt

PVG/PVC Solid Woven Conveyor Belt

-

Advanced Rubber Sheet

Advanced Rubber Sheet

-

Sidewall Conveyor Belt

Sidewall Conveyor Belt

-

Cold Resistant Conveyor Belt

Cold Resistant Conveyor Belt