Fire Resistant Steel Cord Conveyor Belt

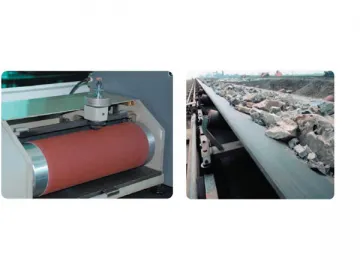

Introduction of Fire Resistant Steel Cord Conveyor Belt

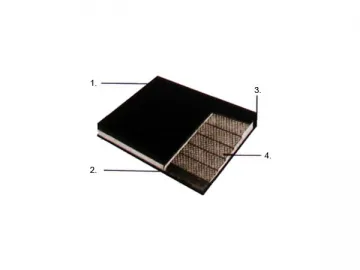

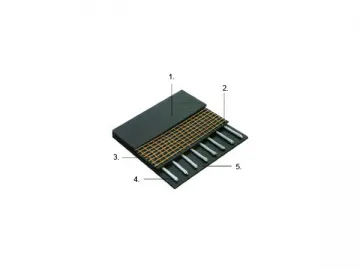

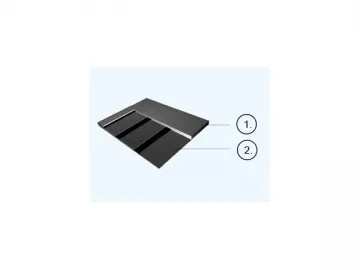

This range of steel cord conveyor belt is a kind of fire resistant conveyor belt which employs galvanized steel wire rope with high strength and low elongation as the carcass. Both upper and lower rubber layers are flame-retardant and anti-static, making the product an ideal choice for heat resistant belt.

With the same structure as general purpose steel wire conveyor belt, our steel cord conveyor belt has higher strength, and can smoothly convey heavy loads. Besides that, the steel wire reinforced rubber conveyor belt is resistant to abrasion, corrosion, impact, and so on.

After the aging test, average bond strength of steel wire rope is no less than 85% of that before aging test. The average bond strength between covering layer and bonding layer is ≥10KN/m. As for flame retardant steel cord belt with fabric layer, the average adhesive strength between covering layer and fabric layer is ≥8KN/m.

Application

Our fire resistant steel cord conveyor belt is suited for the long-distance, speed conveying of a large amount of materials in the areas where fire prevention and explosion proofing are required.

Specifications of Fire Resistant Steel Cord Conveyor Belt

Tensile Strength: 630N/mm ~ 4000N/mm

Width: 800mm ~ 2000mm

Specifications

| Model | ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 | ST5400 |

| Longitudinal Tensile Strength (N/mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 |

| Max. Nominal Diameter of Steel Wire Rope (mm) | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 6.0 | 7.2 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 |

| Space Between Steel Wire Ropes (mm) | 10 ±1.5 | 10 ±1.5 | 12 ±1.5 | 12 ±1.5 | 12 ±1.5 | 12 ±1.5 | 15 ±1.5 | 15 ±1.5 | 15 ±1.5 | 15 ±1.5 | 16 ±1.5 | 17 ±1.5 | 17 ±1.5 |

| Thickness of Upper Covering Layer (mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 |

| Thickness of Lower Covering Layer (mm) | 5 | 5 | 6 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8.5 | 9 |

| Width (mm) | No. of Steel Wire Rope | ||||||||||||

| ST 630 | ST 800 | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST3150 | ST3500 | ST4000 | ST 4500 | ST5000 | ST5400 | |

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | ||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 59 | 55 | 55 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 76 | 77 | 77 | 71 | 66 | 66 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 89 | 90 | 90 | 84 | 78 | 78 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 104 | 104 | 96 | 90 | 90 |

| 1800 | 171 | 143 | 143 | 143 | 143 | 114 | 114 | 117 | 117 | 109 | 102 | 102 | |

| 2000 | 159 | 159 | 159 | 159 | 128 | 128 | 130 | 130 | 121 | 113 | 113 | ||

Rubber Performance

| Item | Performance Index | ||

| Type1 | Type2 | ||

| Tensile Strength | Mpa≥ | 12.0 | 10.0 |

| Elongation at Break | %≥ | 300 | |

Bonding Strength of Steel Wire Rope

| Strength of Belt | Bonding Strength of Steel Wire Rope | |

| Before Thermal Heating | After Thermal Heating | |

| ST630 | 60 | 55 |

| ST800 | 70 | 65 |

| ST1000 | 80 | 75 |

| ST1250 | 95 | 90 |

| ST1600 | 105 | 95 |

| ST2000 | 105 | 95 |

| ST2500 | 130 | 120 |

| ST2150 | 140 | 130 |

| ST3500 | 145 | 140 |

| ST4000 | 150 | 145 |

| ST4500 | 165 | 160 |

| ST5000 | 175 | 170 |

| ST5400 | 180 | 175 |

Safety Performance of Fire Resistant Steel Cord Conveyor Belt

| Item | Type1 | Type2 | |||

| Static Electricity Conductivity | Average surface resistance, Ω, ≤ | 3×10 8 | |||

| Roller Friction | Roller Surface Temperature, ℃, ≤ | 325 | |||

| Test sample doesn't have any direct firing or flameless combustion. | |||||

| Alcohol Torch Burning | Directing Firing | Average Self-extinguishing Time of 4 Samples, s, ≤ | 30 | 3 | |

| Automatic Quench Time of Each Sample, s, ≤ | 45 | 10 | |||

| Flameless Combustion | Average Self-extinguishing Time of 4 Samples, s, ≤ | 120 | - | ||

| Automatic Quench Time of Each Sample, s, ≤ | 180 | - | |||

| Propane Burner Combustion | The whole width is not burned, Length: ≥ 250mm | ||||

As a reputed manufacturer and supplier of rubber conveyer belts, we have the technology know how to offer the best quality conveyor belting. If you have any related demand, please feel free to contact us.

Links:https://globefindpro.com/products/80407.html

-

Abrasion Resistant Conveyor Belt

Abrasion Resistant Conveyor Belt

-

Mercedes-Benz Sonacome Rear Wheel Bolt (DXE008)

Mercedes-Benz Sonacome Rear Wheel Bolt (DXE008)

-

Oil Resistant Conveyor Belt

Oil Resistant Conveyor Belt

-

Standard Fire Resistant Conveyor Belt

Standard Fire Resistant Conveyor Belt

-

DAF Rear Wheel Bolt (DXE016)

DAF Rear Wheel Bolt (DXE016)

-

Chemical Resistant Conveyor Belt

Chemical Resistant Conveyor Belt

-

Special Rubber Sheet

Special Rubber Sheet

-

Ripstop Steel Cord Conveyor Belt

Ripstop Steel Cord Conveyor Belt

-

VOLVO Revolving Wheel Nut (DX0046)

VOLVO Revolving Wheel Nut (DX0046)

-

CC Conveyor Belt

CC Conveyor Belt

-

PVG/PVC Solid Woven Conveyor Belt

PVG/PVC Solid Woven Conveyor Belt

-

Advanced Rubber Sheet

Advanced Rubber Sheet