Bulk Cement Tank Semi Trailer

| Tank Body | |

| Shape | One v-shaped silo, double silo, or triple silo design |

| Dimension | 12000mm×2490mm×3990mm ( The exact size depends on the final design. ) |

| Tare Weight (Semi Trailer) | About 7500kg-15000kg |

| Total Volume (m3) | 30m³ -68 m³ |

| Tanker Body Material | 5mm or 6mm/ Q235 carbon steel |

| End Plate | 5mm or 6mm /Q235 carbon steel |

| Diesel Engine | WEICHAI, Tianhe 4100/4102 or other brands |

| Compressor | BOHAI 10m³/12 m³or other brands |

| Manhole Cover | Carbon steel or Aluminum 500mm(Diameter) |

| Discharging Valve | Diameter is 3 or 4 inch (Material: Aluminum) |

| Discharging Pipe | 3 or 4 inch rubber hose, 1pcs, 6m/each |

| Cat Walk | With (Common model or special design) |

| Chassis | |

| Main Beams | Welded design, Q345 carbon steel |

| Axle | 2 or 3 axles, 12T/13T/16T, BPW/FUWA/HUAJING brand |

| Landing Gear | JOST (D200T) or CHINA BRAND 28T |

| King Pin | JOST 2.00 or 3.5 inch bolt-in king pin |

| Suspension | Mechanical suspension/Germany or America type /Air Suspension |

| Leaf Spring | 90(W)mm×13(Thickness)mm×10 Layers or 100mm×12mm×12 layers |

| Pneumatic Braking System | WABCO RE 6 relay valve; T30/30 T30 Spring brake chamber (TKL brand); 45L air tank |

| Rim | 9.00-22.5/8.00-20/8.5-20 Chinese Brand |

| Tire | 12.00R22.5/315 80R22.5/11.00R20 /12.00R20 Brand can be Optional |

| ABS | Optional |

| Semi Trailer Surface Coating | Sandblasted, anti-rust chassis surface is available with 1 layer of anticorrosive primer and 2 layers of top coats. |

| Accessories | One standard tool box |

| Shipping Terms | By bulk cargo, RORO |

Product Photos

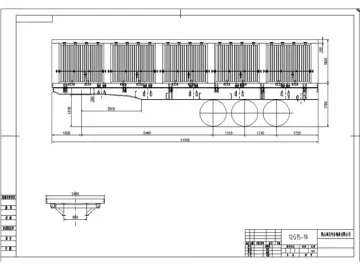

Drawing

Introduction

Cement can be shipped in bulk or, alternatively, in Kraft paper sacks. Bulk cement presents many advantages over bagged cement. The most obvious advantage is material savings as bulk cement does not use packages as bagged cement does. Another advantage lies in the fact that bagged cement needs to be unloaded from the car one bag after another manually while bulk cement requires minimal manual handling task thereby saving labor cost.

Bulk cement is usually delivered and transported in specially constructed vehicles to cement plant, cement warehouse, or large construction site. To serve this bulk transport purpose, we have designed the bulk cement tank semi trailer, which is now covered by the Chinese utility model patent.

Unique to our semi trailer is the V-shaped tank that allows complete discharge of the cement, with only less than 1% being left in the tank. Its reliable, fully closed design keeps moisture from reaching the contents inside the tank.

Please tell us your desired tank capacity and weight, the variety of materials to be transported, particle size, and density. We can then work out a tanker design drawing in the shortest possible time.

CAD software is used to aid our engineers to design a tank with maximum effective capacity that will save your transportation cost.

Well-known brand OEM parts give durability and attractive looks, saving money on operation and repair cost. Specialized welders are used to weld the tank from only one side but form smooth, sturdy, and uniform welds on both sides. High quality welds ensure no air leak.

Fluidized bed is used for increasing the effective capacity of the tank. The tank lid is fitted with a spring to allow easy, effortless opening of the tank. The lid also offers good sealing performance when it is closed.

The inner surface of the tank is sandblasted to receive a corrosion-resistant coat. Polyurethane paint forms a strong bond to the tank surface, giving an attractive, long-lasting and bright look.

High strength steel is used to construct the semi trailer sub-frame, resulting in a lightweight construction that resists twist, shock, and bumps. The vehicle is suitable for driving on various tough terrains.

In addition, the tank semi trailer can be equipped with various kinds of valves, discharge ports, and tank lids, such as in square or round shapes. Choices of these parts can be made all according to your likings.

Links:https://globefindpro.com/products/80444.html

-

Side Dump Semi Trailer

Side Dump Semi Trailer

-

PVC Laminating Film for MDF, WPC

PVC Laminating Film for MDF, WPC

-

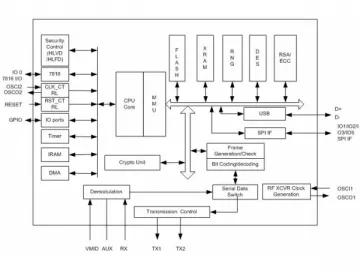

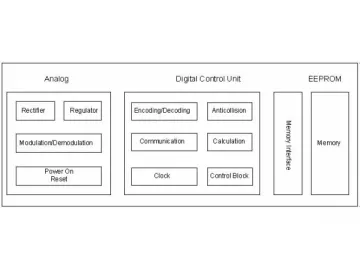

SHC1515 Online Transaction IC Card Chip

SHC1515 Online Transaction IC Card Chip

-

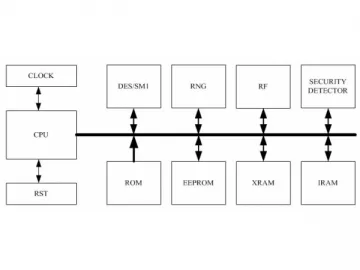

SHC1108S 8k Contactless CPU Card Chip

SHC1108S 8k Contactless CPU Card Chip

-

Mould for O Ring Seals

Mould for O Ring Seals

-

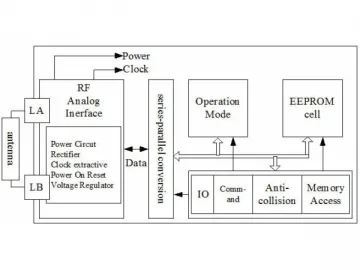

SHC1102 Contactless Single Ticket Chip

SHC1102 Contactless Single Ticket Chip

-

Fuel Tank Semi Trailer

Fuel Tank Semi Trailer

-

Matt Pigment Hot Stamping Foil

Matt Pigment Hot Stamping Foil

-

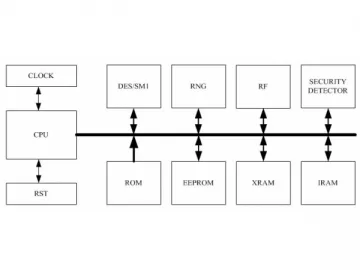

SHC1108 (4k/8k/16k/32k bytes) Contactless CPU Card Chip

SHC1108 (4k/8k/16k/32k bytes) Contactless CPU Card Chip

-

SHC1109 ISO 15693/18000-3 RFID Chip

SHC1109 ISO 15693/18000-3 RFID Chip

-

PVC Laminating Film for PVC Panel

PVC Laminating Film for PVC Panel

-

Hot Stamping Foil for Aluminum Sheet

Hot Stamping Foil for Aluminum Sheet