QT4-15B Fully Automatic Concrete Block Production Line

Introduction

Compared with the QT4-15A, the QT4-15B concrete block production line makes use of the color feeding system that is entirely compatible with the master operating system. It is able to manufacture colored pavers and sidewalk bricks. Equipped with a vibrating case driven by the hydraulic motor, this brick machinery comes with stronger vibration force and higher vibration frequency, which increases the force bearing point of blocks and enhances product quality.

Features

1. The concrete block production line applies the PLC, and realizes computer operation, random signal analysis, malfunction diagnosis and material parameter setting.

2. Fitted with a storage hopper and a feed hopper, it may feed materials in a fixed quantity, which prevents part of concrete from solidifying in advance and minimizes the duration of charging. Owing to the automatic stacker, labor force and production area can be effectively saved.

3. This sidewalk brick making machine uses an especially designed feeding device to pour materials into the molding flask efficiently, for reducing the weight error of finished bricks.

4. Its super steel rack and imported electro-hydraulic components help to ensure stable operation.

| Productive capacity | 400x200x200mm: 6100 PCS /8hr 400x150x200mm: 9600 PCS/8hr 400x100x200mm: 15360 PCS/8hr |

| Power | 29.4 kw |

| Overall size | 3700X1500X2600mm |

| Cycle | 15 s |

| Pallet size | 900x550x30mm |

| Vibration force | 50KN |

| Vibration frequency | 4000-4800/Minute |

| Nominal pressure | 16Mpa |

| Total weight | 6500kg |

| Power source | 380v/50HZ |

Links:https://globefindpro.com/products/80557.html

-

SY1-10 Hydraulic Interlocking Brick Making Machine

SY1-10 Hydraulic Interlocking Brick Making Machine

-

QTJ4-40 Block Making Machine

QTJ4-40 Block Making Machine

-

Side Ejection Punch

Side Ejection Punch

-

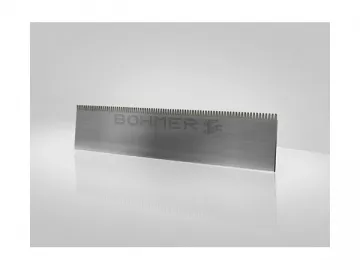

Sharp Teeth Rules

Sharp Teeth Rules

-

SY1-25 Hydraulic Interlocking Brick Making Machine

SY1-25 Hydraulic Interlocking Brick Making Machine

-

PLD800 Two-Hopper Concrete Batching Plant

PLD800 Two-Hopper Concrete Batching Plant

-

SY7502 Hydraulic Interlocking Paver Making Machine

SY7502 Hydraulic Interlocking Paver Making Machine

-

QM4-45 Diesel Engine Block Making Machine

QM4-45 Diesel Engine Block Making Machine

-

QT6-15B Fully Automatic Concrete Block Production Line

QT6-15B Fully Automatic Concrete Block Production Line

-

SY-3000 Curb Stone Making Machine

SY-3000 Curb Stone Making Machine

-

QT10-15 Fully Automatic Concrete Block Production Line

QT10-15 Fully Automatic Concrete Block Production Line

-

PLD1200 Three-Hopper Concrete Batching Plant

PLD1200 Three-Hopper Concrete Batching Plant