Biomass Power Generation System

1. The biomass power generation system is a biomass energy plant used to convert solid biomass with low heating value into gas by gasification, and then uses the gases for power generation after purification processes such as dust removal and decoking. The compatible biomass materials include wastes of agriculture and forestry industries, organic wastes of daily life, and more.

2. With electricity generation capacity of 1,000KW/h, this system offers an ideal solution for construction of biomass power stations, by working in combination with other equipment sets. Our biomass power generation system has a series of characteristics, including small installed capacity, flexible construction, low investment, compact structure, low operational cost, as well as simple operation and maintenance. Also, it has low requirement on gas quality, and offers an effective method to make full use of various organic wastes.

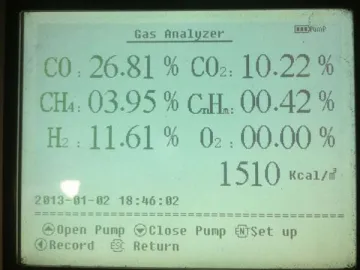

3. As shown in the following images, we have especially constructed a Research and Development Platform to assist product development and improvement. Through hundreds of tests in the past one year, we have made 3 major improvements and 68 minor changes on the platform. Based on this, we are now able to offer perfect biomass power generation systems to our clients.

Construction of the Biomass Power Generation System

This system is mainly made up of the following three parts.

1. Biomass gasifier

The biomass gasifier serves to convert solid biomass into gases. Through control the air supply into the gasification plant, the biomass undergoes incomplete combustion to achieve solid to gas conversion. Finally, combustible gases such as H2, CO, CH4, and CnHm are generated.

2. Gas purification system

The gases generated by the biomass power generation system have high temperature and contains major impurities such as the ash and the tar. So, they need cooling and purification before they are filled into the international combustion generating set. Generally speaking, they should be cooled down to 40℃ or below, and the impurity content should be controlled within 50mg/Nm3.

Typically, the biomass power generation system can be designed with dry type or wet type gas purification system, upon request. The dry type has high cost but produces little waste water. The wet type costs lower but will generate large quantity of sewage. To act in environmental friendly manner, we recommend clients choosing biomass power generation plant outfitted with dry type gas purifier.

3. Biomass electric generator (internal combustion engine generator)

Inside the internal combustion engine, the fuel gas mixes with the air to generate energy which acts to drive the spindle rotate at a high speed. Then, the spindle drives the electric generator for power generation.

For improved performance, our biomass power generation systems never use turbine engines in the electric generator, and the installed engine typically runs at low speed to ensure long term stable operation.

Why Select Our Biomass Power Generation System

1. The biofuel power generating system is achieved based on an exclusive technology leading in international market. It has 18 invention patents.

2. It features material saving (25% lower than counterparts), and generates low temperature during operation.

3. The biomass power generation equipment has high efficiency. Its biomass gasifier has system efficiency higher than 72%, and internal combustion engine generator offers system efficiency higher than 32%.

4. The biomass power generation system is environmental friendly, and produces little noise or waste water pollution.

5. The gas output of gasifier is Chinese leading.

6. High automation degree maximally reduces labor intensity and labor cost.

7. With high safety, reliability and stability, the biomass power generation system is applicable to long term operation for continuous electricity generation.

Links:https://globefindpro.com/products/80983.html