Multifunction CNC Lathe

Description

The multifunction CNC lathe is manufactured with distinctive profile and highlighted by high working speed, high precision, high efficiency, and the capability of processing various complex workpieces. In addition to the mass machining of components like auto accessories, motorcycle parts and valves, it also suits processing in medium and small volumes.

Features

1. This product adopts Mitsubishi or Fanuc numerical control system and servo motor of Japan.

2. It uses the 12-station hydraulic tool post from Liuxin of Taiwan, and chooses tools at the nearest position and only needs 0.3 second for tool changing.3. The spindle works with the SKF series of bearing.

4. The multifunction CNC lathe comes with an automatic timed lubrication system as well as the stainless steel interior protector and the fully enclosed exterior protector.

5. The configurations are provided upon the specific requirements of customers.

Standard Configurations

Fully enclosed protection system, lubrication system, hydraulic system, hollow hydraulic chuck, operating instruction

Optional Configurations

Hydraulic tailstock, hollow hydraulic chuck

Remarks

This product is provided with 9 types. The maximum rotating diameter includes Ø360, Ø500, Ø650, Ø750, etc. (mm)

Technical Parameters

| Item | CH1151H | CH1151BH |

| Maximum rotating diameter of machine tool | Ø360mm | |

| Maximum cutting diameter of chuck | Ø250mm | |

| Maximum cutting diameter of spindle | Ø150mm | |

| Maximum cutting length of spindle | 300mm | |

| Transverse maximum travel (X axis) | 150mm | |

| Longitudinal maximum travel (Z axis) | 320mm | |

| Spindle bore | Ø56mm | Ø38mm |

| Spindle head | A2-5 | |

| Conicity of spindle inner bore | M.T.No.5 | |

| Spindle speed | 6000r/min. | 4000r/min. |

| Hydraulic chuck size | 6″ | |

| Fast feed (X) | 12m/min. | 10m/min. |

| Fast feed (Z) | 20m/min. | 16m/min. |

| Station | 8 | |

| Standard tool size | 20×20mm | |

| Tool bar size (maximum diameter) | Ø25mm | |

| Guideway in X and Z axises | Precise linear rolling guideway | |

| Servo motor torque in X axis | 8Nm | |

| Servo motor torque in Z axis | 12Nm | |

| Diameter of tailstock sleeve | Ø80mm | |

| Travel of tailstock sleeve | 90mm | |

| Inner bore conicity of tailstock sleeve | M.T.No.3 | |

| Spindle motor type | Servo | Variable frequency |

| Spindle motor power | 5.5/7.5KW | 5.5KW |

| Bed structure | 45° inclined bed | |

| Minimum input unit | 0.001mm | |

| Accuracy of repositioning | ±0.003mm | |

| Cutting fluid capacity | 100L | |

| Surface roughness of workpiece | ≤Ra0.8μm (non-ferrous metal) | |

| ≤Ra1.6μm (steel workpiece) | ||

| Overall dimension (length × width × height) | 2700×1460×1680mm | |

| Net weight | 3000kg | |

| Item | CH1252H | CH1252AH | CH1404H |

| Maximum rotating diameter of machine tool | Ø500mm | Ø750mm | |

| Maximum cutting diameter of chuck | Ø300mm | Ø750mm | |

| Maximum cutting diameter of spindle | Ø250mm | Ø350mm | |

| Maximum cutting length of spindle | 400mm | 870mm | |

| Transverse maximum travel (X axis) | 180mm | 370mm | |

| Longitudinal maximum travel (Z axis) | 500mm | 1050mm | |

| Spindle bore | Ø62mm | Ø63mm | Ø105mm |

| Spindle head | A2-5 | A2-6 | A2-8 |

| Spindle speed | 3000rpm | 5000rpm | 100-2000rpm |

| Hydraulic chuck size | 8″ | 12″ | |

| Fast feed (X) | 10m/min. | 10m/min. | |

| Fast feed (Z) | 20m/min. | 20m/min. | |

| Station | 8 | 12 (Liuxin hydraulic tool post) | |

| Standard tool size | 25 × 25mm | 25 × 25mm | |

| Tool bar size (maximum diameter) | Ø40mm | Ø32mm | |

| Guideway in X and Z axises | Precise linear rolling guideway | Precise linear rolling guideway | |

| Servo motor torque in X axis | 7Nm | 15Nm | |

| Servo motor torque in Z axis | 7Nm | 22Nm | |

| Diameter of tailstock sleeve | Ø63mm | Ø100mm | |

| Travel of tailstock sleeve | 115mm | 210mm | |

| Inner bore conicity of tailstock sleeve | M.T.No.4 | M.T.No.6 | |

| Spindle motor type | Variable frequency | Servo | Variable frequency/servo |

| Spindle motor power | 7.5KW | 7.5/11KW | 15KW |

| Bed structure | 30° oblique triangular bed | 30° oblique triangular bed | |

| Minimum input unit | 0.001mm | 0.001mm | |

| Accuracy of repositioning | 0.005/0.006mm | 0.006/0.008mm | |

| Cutting fluid capacity | 150L | 200L | |

| Surface roughness of workpiece | ≤ Ra0.8μm (non-ferrous metal) | ≤ Ra0.8μm (non-ferrous metal) | |

| ≤ Ra1.6μm (steel workpiece) | ≤ Ra1.6μm (steel workpiece) | ||

| Overall dimension (length × width × height) | 1950 × 1650 × 1680mm | 3375 × 2250 × 1965mm | |

| Net weight | 3400kg | 5400kg | |

Related Names

CNC Turning Machine | CNC Turret Lathe | Metal Machining Equipment

Links:https://globefindpro.com/products/81182.html

-

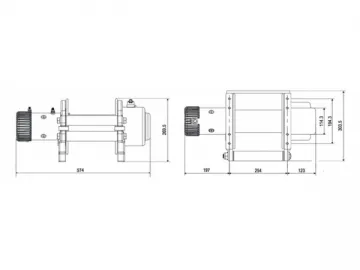

SIC13000 Off-Road Vehicle Winch

SIC13000 Off-Road Vehicle Winch

-

2000lb Boat Winch (P2000-2A)

2000lb Boat Winch (P2000-2A)

-

CNC Vertical Lathe

CNC Vertical Lathe

-

Cantilever Type CNC Plasma Cutter

Cantilever Type CNC Plasma Cutter

-

Hydraulic Upper Roller Universal Plate Rolling Machine

Hydraulic Upper Roller Universal Plate Rolling Machine

-

CNC Lathe

CNC Lathe

-

Mechanical Three-Roller Symmetrical Plate Rolling Machine, Mechanical Three-Roller Asymmetrical Plate Rolling Machine

Mechanical Three-Roller Symmetrical Plate Rolling Machine, Mechanical Three-Roller Asymmetrical Plate Rolling Machine

-

10000lb Winch with Air Compressor (SQ10000)

10000lb Winch with Air Compressor (SQ10000)

-

4000lb Off-Road Vehicle Winch

4000lb Off-Road Vehicle Winch

-

P4000-1W Utility Winch

P4000-1W Utility Winch

-

20000lb Off-Road Vehicle Winch

20000lb Off-Road Vehicle Winch

-

SEC13000 Off-Road Vehicle Winch

SEC13000 Off-Road Vehicle Winch