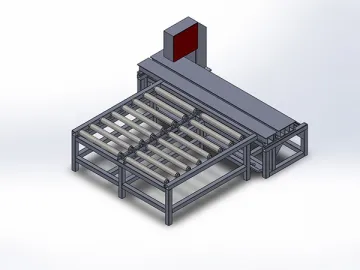

Vertical Machining Center

Features

1. The vertical machining center is designed with deep shaft system which features high speed, high accuracy, high stiffness and stable temperature rise.

2. The spindle bearing is lubricated by high-end lubricating grease and thereby has a long life span.

3. The taper hole of spindle is configured with an air-blowing device for cleaning.

4. The high-stiffness guideways equipped on X, Y and Z directions have strong resistance to vibration and impact, and suit heavy-duty cutting and fine finishing.

5. The vertical machining center is provided with sufficient systems for workpiece cooling.

Technical Parameters

| Item | VMC165 | VMC180 | VMC1110 | VMC160L | VMC180L | VMC1100L | VMC1137 | VMC1158 | |

| Travel | |||||||||

| Operating platform (X) | 600mm | 800mm | 1100mm | 600mm | 800mm | 1000mm | 1300mm | 1500mm | |

| Carriage (Y) | 400mm | 450mm | 550mm | 400mm | 500mm | 700mm | 800mm | ||

| Spindle box (Z) | 500mm | 550mm | 600mm | 480mm | 510mm | 650mm | 700mm | ||

| Distance from spindle central line to stand column and guideway surface | 450mm | 550mm | 610mm | 484mm | 550mm | 785mm | 800mm | ||

| Distance from spindle end face to operating platform | 138-648mm | 150-700mm | 150-750mm | 90-570mm | 155-665mm | 150-800mm | 1700-870mm | ||

| Operating platform | |||||||||

| Dimension | 800×400mm | 950×460mm | 1200×580mm | 750×400mm | 930×510mm | 1130×510mm | 1400×710mm | 1700×800mm | |

| Bearing capacity | 500kg | 600kg | 800kg | 450kg | 600kg | 600kg | 1000kg | 1500kg | |

| T groove (width × groove numbers × spacing) | 18×3×135mm | 18×3×150mm | 18×5×120mm | 18×3×110mm | 18×3×160mm | 18×5×152.5mm | 22×5×135mm | ||

| Spindle | |||||||||

| Taper hole | BT40 | B-T40 | BT50 | ||||||

| Speed | 60-8000rpm | 8000rpm | 50-6000rpm | ||||||

| Power of main motor | 7.5/11KW | 7.5/11KW | 11/15KW | 7.5/11KW | 15/18.5KW | ||||

| Tool unloading way of spindle | Pneumatic | Pneumatic | Pneumatic | Pneumatic | Pneumatic | ||||

| Feed | |||||||||

| Moving speed in X and Y directions | 0-12m/min. | 0-16m/min. | 0-20m/min. | 0-20m/min. | 20m/min. | ||||

| Moving speed in Z direction | 0-12m/min. | 0-16m/min. | 0-20m/min. | 0-20m/min. | 20m/min. | ||||

| Motor torque in X, Y and Z directions | 12Nm | 12Nm | 22Nm | 12Nm | 22Nm (α motor) | ||||

| Accuracy of repositioning (X/Y/Z) | ±0.003mm | ±0.003mm | ±0.003 mm | ±0.003mm | ±0.003mm | ||||

| Tool changing system | |||||||||

| Tool magazine capacity | Horizontal type: 16 pieces | Horizontal type: 16 pieces | Horizontal type: 16 pieces | Horizontal type: 24 pieces | Horizontal type: 24 pieces | ||||

| Vertical type: 20 pieces | Vertical type: 20 pieces | Vertical type: 12 pieces | Vertical type: 20 pieces | ||||||

| Maximum diameter of adjacent tools | Ø85mm (vertical type) | Ø80mm (horizontal type) | Ø85mm (horizontal type) | Ø80mm (horizontal type) | Ø127mm | ||||

| Ø90mm (vertical type) | Ø90mm (vertical type) | Ø110mm (vertical type) | Ø90mm (vertical type) | ||||||

| Maximum diameter of nonadjacent tools | Ø130mm (horizontal type) | Ø130mm (horizontal type) | Ø130mm (horizontal type) | Ø130 mm (horizontal type) | Ø150mm | ||||

| Ø150mm (vertical type) | Ø150mm (vertical type) | Ø220mm (vertical type) | Ø150mm (vertical type) | ||||||

| Maximum tool length | 350mm (horizontal type) | 300mm (horizontal type) | 350mm (horizontal type) | 300mm (horizontal type) | 300mm | ||||

| 250mm (vertical type) | 250mm (vertical type) | 250mm (vertical type) | 250mm (vertical type) | ||||||

| Maximum tool weight | 8kg (horizontal type) | 7kg (horizontal type) | 8kg (horizontal type) | 7kg (horizontal type) | 15kg | ||||

| 8kg (vertical type) | 8kg (vertical type) | 8kg (vertical type) | 8kg (vertical type) | ||||||

| Tool changing time (tool to tool) | 2s(horizontal type) | 2s (horizontal type) | 3s | ||||||

| Other | |||||||||

| Minimum input unit (X/Y/Z) | 0.001mm | 0.001mm | 0.001mm | ||||||

| Minimum input unit (X/Y/Z) | 0.001mm | 0.001mm | |||||||

| Overall dimension (length × width × height) | 2280×1880×2100m | 2400×2110×2800mm | 2900×2350×2900m | 3380×2060×2350mm (including chip cleaner) | 3950×2100×2600mm (including chip cleaner) | 3950×2100×2600mm (including chip cleaner) | 3500×3390×2865mm | 4286×3110×3059mm | |

| Net weight | 4500kg | 5000kg | 7000kg | 3900kg | 5150kg | 5480kg | 12000kg | 15000kg | |

Related Names

Vertical Turning Center | Hard Metal Machining Tool | Metal Shaping Equipment

Scan QR to Read

Links:https://globefindpro.com/products/81189.html

Links:https://globefindpro.com/products/81189.html

Recommended Products

-

EMM21 Series C-Frame Fixed Bolster Mechanical Presses

EMM21 Series C-Frame Fixed Bolster Mechanical Presses

-

Vertical Band Saw

Vertical Band Saw

-

Portable CNC Plasma Cutter

Portable CNC Plasma Cutter

-

QC12Y/K Hydraulic Swing Beam Shearing Machine

QC12Y/K Hydraulic Swing Beam Shearing Machine

-

Gantry Type CNC Plasma Cutter

Gantry Type CNC Plasma Cutter

-

Hydraulic Three-Roller Symmetrical Plate Rolling Machine

Hydraulic Three-Roller Symmetrical Plate Rolling Machine

-

CNC Lathe

CNC Lathe

-

Hydraulic Upper Roller Universal Plate Rolling Machine

Hydraulic Upper Roller Universal Plate Rolling Machine

-

Cantilever Type CNC Plasma Cutter

Cantilever Type CNC Plasma Cutter

-

CNC Vertical Lathe

CNC Vertical Lathe

-

2000lb Boat Winch (P2000-2A)

2000lb Boat Winch (P2000-2A)

-

SIC13000 Off-Road Vehicle Winch

SIC13000 Off-Road Vehicle Winch

Hot Products