GWC25-205-1025 Roof Panel Embossing and Roll Forming Machine

Features

The GWC25-205-1025 roof panel embossing and roll forming machine enjoys unique characteristics as follows besides the common features it shares with machines of the same series.

1. This machine can reduce one pitch and becomes GWC25-205-820, and the feeding width is adjusted to 1000mm accordingly. So, this is a dual-use product.

2. Our product is able to make use of the embossing machine to form lozenge pattern which is also called diamond pattern. Based on customer's requirement, other patterns are also available.

3. If needed, this roof panel embossing and roll forming machine could work without the embossing machine in order to fabricate common roof panel without any patterns, though the embossing machine is applicable for any panel.

Processing Flow

Passive decoiling → embossing → guided material feeding → roll forming → cut-to-length→ offloading

Composition

1. 5T passive decoiler

2. Embossing machine

3. Shape forming machine

4. Hydraulic shear

5. Hydraulic station

6. PLC control cabinet

7. Run out table

Specifications

| Model | GWC25-205-820/1025 | Note |

| Applicable material | Color plate, galvanized sheet, galvalume sheet and aluminum plate. | This machine is customizable upon each customer's requirements and the characteristics of processed material. The patterns could be changed as requested by customer. |

| Feeding width | 1000/1200mm | |

| Processing thickness | 0.3-0.8mm | |

| Roller material | 45# steel coated with hard chrome | |

| Main motor power / hydraulic station power | 3kW / 3kW | These parameters can be set according to the required production capacity. |

| Forming passes | 18 | |

| Forming speed | 5-15 meters/minute | |

| Machine dimensions | 9.5×1.3×1.2m | |

| Machine weight | 8T |

Related Names

Metal Roof Forming Equipment | Embossed Roofing Sheet Machine | Decorative Metal Roofing Machine

Links:https://globefindpro.com/products/81379.html

-

GWC15-1239 Beaver Roof Tile Roll Forming Machine

GWC15-1239 Beaver Roof Tile Roll Forming Machine

-

Wall Panel

Wall Panel

-

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine

-

Roof Panel Bending Machine

Roof Panel Bending Machine

-

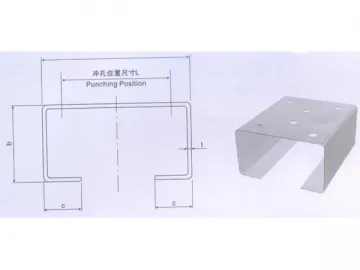

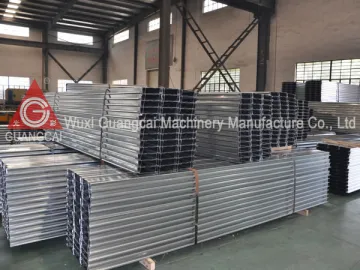

Purlin

Purlin

-

GWC900-820 Double Layer Roof Panel Roll Forming Machine

GWC900-820 Double Layer Roof Panel Roll Forming Machine

-

Guide Rail Roll Forming Machine

Guide Rail Roll Forming Machine

-

GWC65-185-555 Floor Deck Roll Forming Machine

GWC65-185-555 Floor Deck Roll Forming Machine

-

Horizontal/Vertical Turret Milling Machine

Horizontal/Vertical Turret Milling Machine

-

Hydraulic Press Brake

Hydraulic Press Brake

-

Hydraulic Automatic Feed Pipe Cutting Circular Saw

Hydraulic Automatic Feed Pipe Cutting Circular Saw

-

Mechanical Ironworker

Mechanical Ironworker