Cast Iron Grinding Balls

Our cast iron grinding balls can be divided into three categories including the high chromium type, medium chromium type and the low chromium type.

1. The Quality Index of the High Chromium Type

The chromium content of the high chromium type product is greater than or equal to 10.0%. And the carbon content is between 1.80% and 3.20%. It is required by the national standard that the hardness of the high chromium type product must be no less than 58HRC, and that the impact value should be greater than or equal to 3.0J/cm2. This type of product must go through the hot quenching and the tempering treatment to come up to the hardness.

Currently at home, there are two quenching methods for this type of product including oil quenching and wind quenching. If the tested hardness of this type of product is below 54HRC, then it shows that the quenching treatment is omitted.

2. The Quality Index of the Medium Chromium Type

The medium chromium type cast iron grinding ball is defined as the chromium content ranging from 3.0% to 7.0%, and the carbon content coming between 1.80% and 3.20%. Its impact value should be no less than 2.0J/cm2. The national standard requires the hardness of this type of product should be greater than or equal to 47HRC. For ensuring the quality, the medium chromium type product should be processed with high temperature tempering to eliminate the casting stress.

If the surface of the steel ball assumes the dark red color, it proves that the steel ball has been processed with high temperature tempering. If the surface of the steel ball still comes with the metal color, then, we can judge that the steel ball doesn’t go through the high temperature tempering treatment.

3. The Quality Index of the Low Chromium Type

Generally, the low chromium cast iron grinding ball contains the chromium with the content of 0.5% to 2.5%, and the carbon with the content ranging from 1.80% to 3.20%. Accordingly, in line with the national standard, the hardness of the type of product should be no less than 45HRC and the impact value should be no less than 1.5J/cm2. The low chromium type product also needs the high temperature tempering treatment to guarantee the quality. The treatment can eliminate the casting stress. If the steel ball has dark red surface, it has gone through the high temperature tempering treatment. If the surface still shows the metal color, the steel ball is not treated with high temperature tempering.

The cast iron grinding ball is often applied for various rod mills in large scale mine, cement plant, chemical plant, power station, quartz sand plant, silica sand factory, etc.

Technological Production Process

Raw Material Inspection - Material Proportion - Intermediate Frequency Furnace Heating and Smelting - Pouring via Steel Die - Quenching Treatment - Tempering Treatment - Inspection - Packaging

Product Quality Standard and Inspection Method

1. The chemical composition of the high chromium type product should conform to the regulations of the table below. We can also manufacture the product with special chemical composition in accordance with the requirements of the customers.

| Code | Chemical Composition (Mass Fraction) % | |||||||||

| Cr | C | Si | Mn | Mo | Cu | V | Ti | P | S | |

| ZQCrG1 | 10-16 | 2.0-3.5 | ≤1.0 | 0.5-2.5 | ≤1.0 | ≤1.0 | ≤0.3 | ≤0.15 | ≤0.1 | ≤0.1 |

| ZQCrG2 | 16-22 | |||||||||

| ZQCrG3 | 22-28 | |||||||||

2. The nominal diameter, allowable deviation, maximum diameter and minimum diameter of the high chromium type cast iron grinding ball should be in accordance with the following table.

| Nominal Diameter | 20 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

| Allowable Deviation of Diameter | 2.0-1.0 | 2.0-1.0 | 3.5-1.0 | |||||||

| Difference between the Maximum Diameter and Minimum Diameter | ≤1.8 | ≤2.4 | ≤3.0 | ≤3.6 | ≤4.2 | ≤4.6 | ||||

3. The high chromium type product can be manufactured with the mechanical properties following the requirements of the customers.

| Code | Surface Hardness (HRC) | Impact Test (Ak) | Impact Fatigue Life (Times) |

| ZQCrG1 | ≥58 | ≥3 | ≥10000 |

| ZQCrG2 | |||

| ZQCrG3 |

Note

1. We make the falling ball impact fatigue test on the testing machine with the standard height of 3.5m by using the product with the diameter of 100mm. The impact fatigue life of the product with other diameters can be calculated by reference to the following formula.

Nx=N×100/D

N - The number of times.

2. The impact toughness and the impact fatigue life are usually not taken as the basis of delivery.

Surface Quality

The surface of the cast iron grinding ball is not allowed to have the casting defects such as the crack, and the obvious gas porosity, inclusion, shrinkage cavity, cold shut, elephant skin, etc.

Internal Quality

It is not allowed to have the shrinkage cavity, shrinkage porosity, gas porosity, inclusion, and other cavity defects on the section cutting plane passing through the pouring gate center and the ball center.

Testing Method and Inspection Rules

1. Impact Test

The test is implemented by cutting the product through the pouring gate to get the unnotched specimen of 10mm×10mm×55mm.

2. Rockwell Hardness Test Specimen Preparation

Use the grinding machine to grind the surface of the cast iron grinding ball until the flat surface appears with the thickness of the part being ground off being 1.5mm to 5mm.

3. Chemical Composition Inspection

When the pouring metal amount in the smelting furnace exceeds 0.5t, the personnel should inspect the pouring metal in all the smelting furnaces. When the pouring metal amount in the smelting furnace is less than 0.5t, the personnel can check the smelting furnace one time in each work shift. If one sample is unqualified, the re-inspection should be carried out with the inspected sample doubled. If there is still unqualified sample, then, the pouring metal in this batch of smelting furnaces is unqualified.

4. Surface Hardness Inspection

Take the sample cast iron grinding balls with the amount of no less than 5 from different parts of the heat treatment furnaces in each batch. After the inspection, if there is one unqualified sample, then take the products randomly with the amount doubled for re-inspection. If there is still one unqualified sample, then, this batch of products is unqualified.

5. Internal Quality Inspection

When continuously manufacturing every 100t product of the same type, then select one product with the largest dimension randomly for inspection. If the inspection result is disqualification, then, re-inspection with the sample amount doubled should be carried out. If the chemical composition is qualified, this batch of products is allowed to be processed with the heat treatment again. If unqualified product still exists, then, this batch of products is unqualified.

We can provide the most appropriate cast iron grinding balls in line with the requirements of customers. Please contact us to get the detailed information.

Related Names

Continuous Milling Balls | Chrome Steel Ball | Cement Grinding Balls

Links:https://globefindpro.com/products/81481.html

-

Forged Steel Grinding Balls

Forged Steel Grinding Balls

-

Y81-1350 Hydraulic Metal Baler

Y81-1350 Hydraulic Metal Baler

-

PE Transparent Protection Film

PE Transparent Protection Film

-

Carbon Steel Pipe Cap

Carbon Steel Pipe Cap

-

Patented Automatic Steel Grinding Ball Production Line

Patented Automatic Steel Grinding Ball Production Line

-

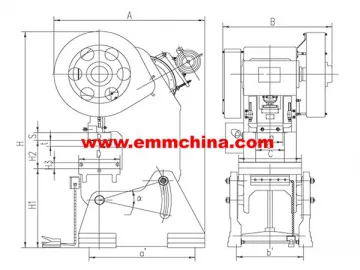

EMH23 Series C-frame High Performance Inclinable Presses

EMH23 Series C-frame High Performance Inclinable Presses

-

Carbon Steel Reducing Tee

Carbon Steel Reducing Tee

-

Laminated Paper Bag

Laminated Paper Bag

-

GWC76-305-915 Floor Deck Roll Forming Machine

GWC76-305-915 Floor Deck Roll Forming Machine

-

Carbon Steel 90 Degree Short Radius Elbow

Carbon Steel 90 Degree Short Radius Elbow

-

5 Axis Machining Center

5 Axis Machining Center

-

Carbon Steel Equal Tee

Carbon Steel Equal Tee