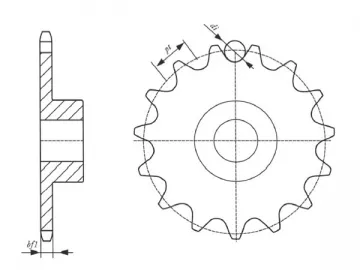

Heavy Duty Offset Link Roller Chain Sprocket

Our sprocket wheel for meshing with heavy duty offset link roller chains undergoes integral hardening and tempering, so as to offer superior mechanical performance as well as high strength and deformation resistance. Due to this, it supports working with high load.

Through high frequency quenching, the teeth of our roller chain sprocket come with high hardness and superb wearing resistance.

According to the application demands, this range of product can be processed into the welded type so as to save users' cost.

| Matching Chain No. | Chain Pitch (mm) | Outer diameter of chain roller (max.) (mm) | Height of chain sidebar (max.)(mm) | Inner width of narrow end (b1) | |

| Nominal value (Min. b1)=0.95b1) (mm) | ANSI standard (min.)(mm) | ||||

| 2010 | 36.5 | 31.75 | 47.80 | 38.10 | 36.6 |

| 2512 | 77.9 | 41.28 | 60.5 | 39.60 | 38.1 |

| 2814 | 88.90 | 44.45 | 60.50 | 38.10 | 36.6 |

| 3315 | 103.45 | 45.24 | 63.50 | 49.30 | 47.2 |

| 3618 | 114.30 | 57.15 | 79.20 | 52.30 | 50.3 |

| 4020 | 127.00 | 63.50 | 91.90 | 69.90 | 67.1 |

| 4824 | 152.40 | 76.20 | 104.60 | 76.20 | 73.2 |

| 5628 | 177.80 | 88.90 | 133.40 | 82.60 | 79.2 |

Related Names

Industrial Steel Sprocket | Wear Resistant Sprocket | Weld On Sprocket

Scan QR to Read

Links:https://globefindpro.com/products/81829.html

Links:https://globefindpro.com/products/81829.html

Recommended Products

-

Conveyor Chain for Metallurgy Industry

Conveyor Chain for Metallurgy Industry

-

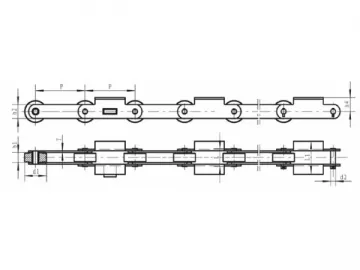

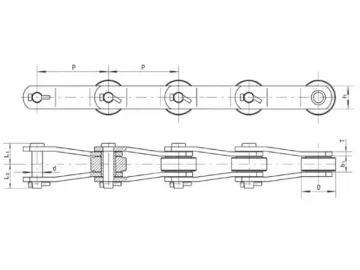

Heavy Duty Extended Pitch Roller Chain

Heavy Duty Extended Pitch Roller Chain

-

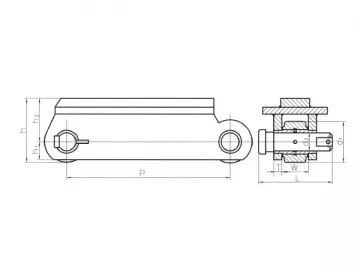

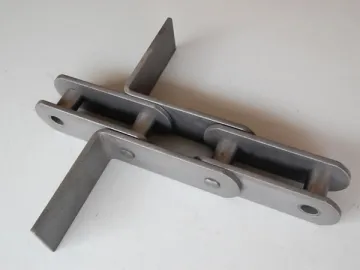

Offset Link Chain for Sugar Industry

Offset Link Chain for Sugar Industry

-

Double Pitch Precision Roller Chain Sprocket

Double Pitch Precision Roller Chain Sprocket

-

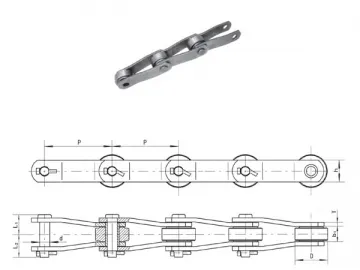

Offset Link Chain for Palm Oil Industry

Offset Link Chain for Palm Oil Industry

-

Scraper Conveyor Chain Sprocket

Scraper Conveyor Chain Sprocket

-

Conveyor Chain for Grain Machines

Conveyor Chain for Grain Machines

-

Elevator Chain

Elevator Chain

-

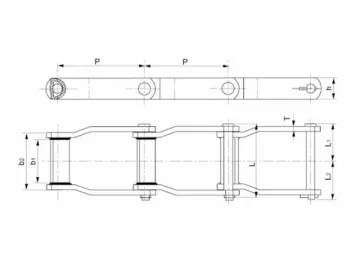

Wide Series Welded Steel Chain

Wide Series Welded Steel Chain

-

35cm Ku Band Satellite Dish

35cm Ku Band Satellite Dish

-

Hydraulic Press B

Hydraulic Press B

-

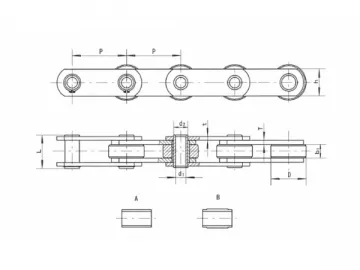

Hollow Pin Chain for Palm Oil Industry

Hollow Pin Chain for Palm Oil Industry