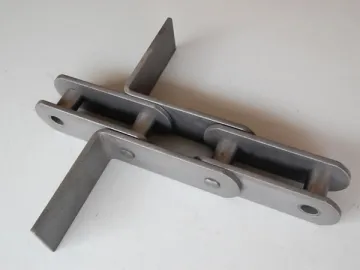

Elevator chain products have high requirements on wearing resistance and tensile strength. For this purpose, we carry out secondary heat treatment for the rollers and bushings. The two chain components are firstly carburized, and then undergo secondary heat treatment to offer increased surface hardness and core part toughness. These processes ensure improved crushing strength.

As this range of roller chain is primarily used for material lifting in vertical direction, there is a high requirement on its framework firmness so as to prevent the chain getting loosening up. To meet this requirement, we manufacture the product parts with optimized allowance to ensure prefect match, and meanwhile, a hydraulic press is applied to assemble the chain components.

Our elevator chain is commonly used in cement, mining, grain processing, road construction, and steelworks industries. It assists material elevating, and is accommodate to severe working environments. It works normally even if it is attached with heavy dust and hard particles.

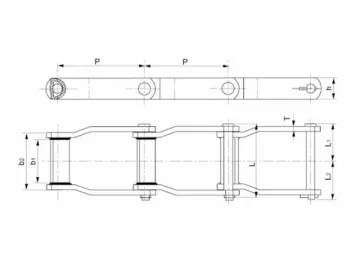

Bucket Elevator Chain | Chain No. | Pitch P (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin b2 (mm) | Inner width of inner link b1(min) (mm) | Thickness of sidebar T (mm) | Height of sidebar h2 (mm) | Height of attached plate h2 (mm) | Tensile strength Q (min.)(KN) |

| NE model lifting chain for elevators |

| NE15-101.6 | 101.6 | 26.5 | 11.5 | 70 | 27 | 6 | 35 | 35 | 128.1 |

| NE30-152.4 | 152.4 | 35 | 15.5 | 90 | 36.5 | 8 | 50 | 50 | 245 |

| NE50-152.4 | 152.4 | 35 | 15.5 | 90 | 36.5 | 8 | 50 | 110 | 245 |

| NE100-200 | 200 | 42 | 19.1 | 120 | 51.8 | 10 | 60 | 125 | 375 |

| NE150-200 | 200 | 48.5 | 22.23 | 120 | 57.8 | 10 | 60 | 125 | 375 |

| NE300-250 | 250 | 70 | 35 | 165 | 75 | 16 | 100 | 150 | 450 |

| NE300-250A | 250 | 63.5 | 31.75 | 146 | 67.4 | 12 | 90 | 150 | 450 |

| NP152.4 | 152.4 | 357 | 15.88 | 88 | 38 | 7.9 | 45 | 105 | 245 |

| FE12600 | 152.4 | 35 | 15.88 | 86 | 36.5 | 7.9 | 45 | 120 | 245 |

| NE100/2L | 200 | 44.5 | 19.05 | 114 | 53 | 10 | 60 | 125 | 400 |

| NE150-B/2L | 200 | 44.5 | 19.05 | 114 | 53 | 10 | 60 | 125 | 400 |

| NE200/2L | 250 | 63.5 | 31.75 | 140 | 67.4 | 12 | 90 | 150 | 750 |

| 9060 G4/4L | 152.4 | 34.93 | 19.05 | 94.5 | 38.1 | 9.5 | 50.8 | 120 | 312 |

| P152.4-A/2L | 152.4 | 36 | 17.33 | 85 | 36.5 | 8 | 50 | 105 | 160 |

| DK 19200M G4/2L | 200 | 38.1 | 15.77 | 86 | 36.5 | 8 | 45 | 125 | 312 |

| NE150-A/2L | 200 | 48.5 | 22.23 | 122 | 57.6 | 10 | 75 | 125 | 529 |

| P152.4 3L | 152.4 | 31.75 | 15.77 | 109 | 54 | 9.6 | 38.1 | 139.7 | 145 |

| P125/2L | 125 | 52 | 17 | 80 | 31 | 8 | 580 | 100 | 219.52 |

| FE12600-S/2L | 152.4 | 34.93 | 15.88 | 86 | 36.5 | 7.9 | 45 | 120 | 160 |

| NE150/2L | 200 | 48.5 | 22.23 | 118 | 57.6 | 10 | 75 | 125 | 529 |

| NE300-250/2L | 250 | 70 | 35 | 165 | 75 | 16 | 100 | 150 | 1107 |

| P152.4/2L | 152.4 | 35.7 | 15.88 | 88 | 38 | 7.9 | 45 | 105 | 160 |

| DS17200-S G4/2L | 200 | 40.08 | 19.05 | 106.5 | 50.8 | 9.5 | 50.8 | 130 | 260 |

| P250-G4/2L | 250 | 73 | 38.5 | 183.5 | 82 | 16 | 115 | 180 | 1200 |

| NE300 | 250 | 70 | 35 | 165 | 75 | 16 | 100 | 150 | 1107 |

| Dimensions of attached plate |

| Chain No. | d4 (mm) | L1 (mm) | L2 (mm) |

| NE15-101.6 | 10 | 50 | 50 |

| NE30-152.4 | 15 | 75 | 70 |

| NE50-152.4 | 15 | 75 | 70 |

| NE100-200 | 15 | 75 | 70 |

| NE150-200 | 18 | 100 | 80 |

| NE300-250 | 18 | 140 | 100 |

| NE300-250A | 20 | 140 | 100 |

| NP152.4 | 15 | 75 | 70 |

| FE12600 | 15 | 75 | 70 |

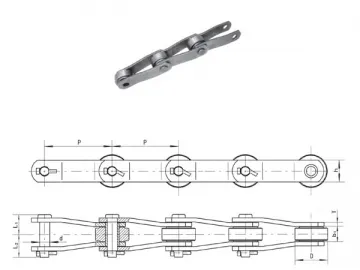

Bucket Lifter Chain

| Chain No. | Pitch P (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin L (mm) | Inner width of inner link b1 (mm) | Thickness of sidebar T (mm) | Height of sidebar h2 (mm) | Height of attachment h2 (mm) | Tensile strength Q (min.)(KN) |

| NP150 | 150 | 31.8 | 14.17 | 69 | 30 | 6.35 | 38.1 | 105 | 200 |

| NP228.6 | 228.6 | 62 | 24.2 | 136 | 64 | 13 | 70 | 70 | 440 |

| Dimensions of attached plate |

| Chain No. | d4 (mm) | L1 (mm) | L2 (mm) |

| NP150 | 14 | 75 | 75 |

| NP228.6 | 17 | 355.6 | |

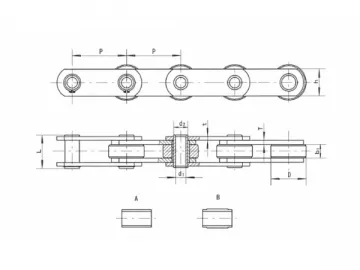

| Chain No. | Pitch P (mm) | Inner width of inner link W (mm) | Diameter of roller D (mm) | Sidebar | Pin | Dimension of attachment | Tensile strength(KN) |

| Height H (mm) | Thickness T (mm) | Diameter d (mm) | Length L (mm) | H2 (mm) | N (mm) | X (mm) | Y (mm) |

| NSE200 | 100 | 51.8 | 44.5 | 60 | 10 | 19.1 | 111.5 | 150 | 18 | 100 | 105 | 420 |

| NSE300 | 100 | 57.6 | 48.5 | 75 | 7.5 | 22.23 | 120 | 150 | 18 | 100 | 105 | 520 |

| NSE400 | 125 | 67.4 | 63.5 | 90 | 12 | 31.75 | 139.3 | 180 | 18 | 125 | 130 | 735 |

| NSE500-1 | 125 | 75 | 70 | 100 | 16 | 35 | 170 | 180 | 18 | 125 | 130 | 980 |

| NSE500-2 | 125 | 75 | 71.5 | 102 | 16 | 36 | 165 | 180 | 18 | 125 | 130 | 1200 |

| NSE600H | 125 | 75 | 75 | 105 | 16 | 40 | 165 | 185 | 18 | 125 | 136 | 1260 |

| NSE700 | 150 | 85 | 85 | 125 | 16 | 48 | 180 | 226 | 22 | 150 | 165 | 1470 |

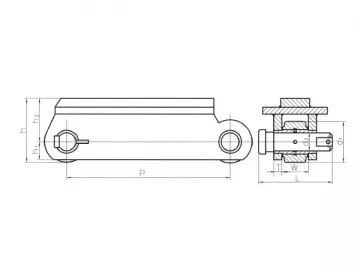

| Model | P (mm) | B1 (mm) | D1 (mm) | H (mm) | H1 (mm) | T (mm) | B2 (mm) | D2 (mm) | L1 (mm) | L2 (mm) | D4 (mm) | B3 (mm) | B4 (mm) |

| P200/2L | 200 | 64.4 | 42 | 62 | 54.85 | 8 | 100 | 21 | 100 | 100 | 16 | 47 | 63.8 |

| P150/2L | 150 | 43.6 | 31.8 | 38.1 | 39.8 | 6.35 | 69 | 14.17 | 75 | 75 | 14 | 30 | 43.2 |

| P100/4L | 100 | 73 | 40.1 | 50 | 58 | 10 | 111 | 19.05 | 100 | 100 | 16 | 52 | 72.5 |

| TBH100/4L | 100 | 79 | 50.8 | 72 | 64 | 10 | 120.5 | 25 | 100 | 100 | 18 | 57.5 | 78 |

| C100-K4/4L | 100 | 89 | 52 | 72 | 61.5 | 10 | 134 | 27 | 100 | 100 | 18 | 66.3 | 88.3 |

| C125-K4/4L | 125 | 79.8 | 50.8 | 70 | 63.5 | 10 | 101 | 24 | 125 | 110 | 22 | 57 | 79 |

| P76.2-K4/4L | 76.2 | 54.5 | 34.9 | 44.5 | 46.25 | 7.9 | 70.9 | 16 | 75 | 75 | 14 | 37 | 52.8 |

| P100-K4/4L | 100 | 73 | 40.1 | 50 | 58 | 10 | 111 | 19.05 | 100 | 100 | 16 | 52 | 72.5 |

| P125-K4/4L | 125 | 79.8 | 50.8 | 70 | 63.5 | 10 | 121 | 24 | 125 | 110 | 18 | 57 | 79 |

| P100-G4-Y1/4L | 100 | 80 | 50 | 75 | 60 | 10 | 120 | 26 | 100 | 115 | 16 | 55 | 75.9 |

| P75-G4/4L | 75 | 43 | 29 | 38 | 37.5 | 6 | 68 | 14.17 | 75 | 80 | 15 | 30 | 42.5 |

| Model | P1 (mm) | P2 (mm) | H1 (mm) | H2 (mm) | B1 (mm) | B2 (mm) | B3 (mm) | B4 (mm) | B5 (mm) | D1 (mm) | D2 (mm) | D3 (mm) | T (mm) | L (mm) |

| P152.4 | 152.4 | 60 | 45 | 79 | 61.7 | 94 | 44.5 | 61 | 38 | 57.2 | 15.77 | 14.8 | 8 | |

| DT-30A-A | 152.4 | 60 | 45 | 77 | 57.5 | 89.5 | 39.5 | 56 | 38 | 38.1 | 17.33 | 13 | 8 | 120 |

| DT-30A | 152.4 | 60 | 45 | | 58 | 89.5 | 40 | 56 | 37.5 | 38.1 | 16 | 13 | 8 | 120 |

| Model | P(mm) | D1(mm) | D2(mm) | H1(mm) | B2(mm) | B1(mm) | T(mm) | Tensile strength(KN) |

| 4004 | 228.6 | 76.2 | 25.4 | 63.5 | 114 | 6638 | 12.7 | 337.8 |

| 4065 | 228.6 | 108 | 31.75 | 88.9 | 170.2 | 77.72 | 15.88 | 995 |

| P228.6-D | 228.6 | 80 | 24.2 | 70 | 136 | 64 | 13 | 440 |

| P228.6 | 228.6 | 62 | 24.2 | 70 | 136 | 64 | 13 | 440 |

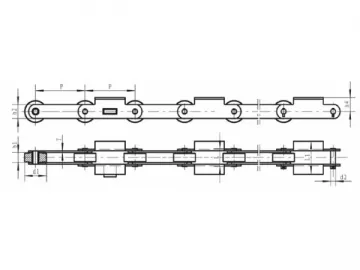

| Chain No. | Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Height of sidebar h1 (mm) | Thickness of sidebar T (mm) | Length of pin b2 (mm) | Diameter of pin d2 (mm) | Height of attached plate h2 (mm) | Tensile strength Q (min.)(KN) |

| L (mm) | f (mm) | h2 (mm) |

| DT-10 | 100 | 20.5 | 44 | 26 | 4 | 42 | 9.54 | 40 | 69 | 25 | 82 |

| DT-15A | 101.6 | 15.7 | 38.1 | 26 | 4 | 37.1 | 9.54 | 40 | 63.5 | 22.3 | 82 |

| DT-15B | 101.6 | 31 | 44.45 | 38 | 7.9 | 75.5 | 15.88 | 40 | 110 | 35 | 140 |

| DT-50 | 160 | 33.7 | 38 | 50 | 8 | 82.5 | 15.88 | 60 | 130 | 50 | 240 |

| DT-35 | 160 | 36 | 37.5 | 40 | 6 | 73 | 15.88 | 60 | 130 | 35 | 180 |

| DT-30D | 152.4 | 37 | 38.1 | 45 | 8 | 86.6 | 16 | 60 | 120 | 37.5 | 224 |

| DT-30A | 152.4 | 40 | 38.1 | 45 | 8 | 89.6 | 16 | 60 | 120 | 37.5 | 224 |

| DT-150 | 200 | 57.6 | 48.5 | 75 | 10 | 126 | 22.2 | 80 | 160 | 40 | 400 |

| DT-200 | 250 | 67.4 | 63.5 | 90 | 12 | 146 | 31.25 | 120 | 200 | 75 | 580 |

Lifting Chain

| Chain No. | Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Hole height of attached plate (mm) | Central distance of attached plate L1(mm) | Hole diameter of attached plate d4 (mm) | Tensile strengthQ(KN) |

| RU95 | 180 | 85 | 53.5 | 33.2 | 100 | 15 | 200 | 280 | 18 | 950 |

| RU150 | 180 | 100 | 66 | 45.4 | 115 | 20 | 200 | 330 | 18 | 1500 |

| RU200 | 180 | 105 | 78 | 55 | 150 | 20 | 200 | 330 | 18 | 2000 |

Related Names

Lifting Chain | Drag Chain | Security Chain

Conveyor Chain for Grain Machines

Conveyor Chain for Grain Machines

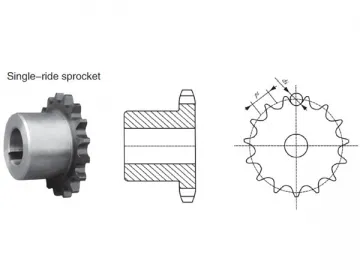

Heavy Duty Offset Link Roller Chain Sprocket

Heavy Duty Offset Link Roller Chain Sprocket

Conveyor Chain for Metallurgy Industry

Conveyor Chain for Metallurgy Industry

Heavy Duty Extended Pitch Roller Chain

Heavy Duty Extended Pitch Roller Chain

Offset Link Chain for Sugar Industry

Offset Link Chain for Sugar Industry

Double Pitch Precision Roller Chain Sprocket

Double Pitch Precision Roller Chain Sprocket

Wide Series Welded Steel Chain

Wide Series Welded Steel Chain

35cm Ku Band Satellite Dish

35cm Ku Band Satellite Dish

Hydraulic Press B

Hydraulic Press B

Hollow Pin Chain for Palm Oil Industry

Hollow Pin Chain for Palm Oil Industry

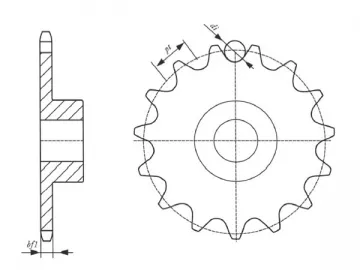

Simplex Sprocket

Simplex Sprocket

Curing Car

Curing Car