FH200 Sanitary Double-seal Mix Proof Valve

The FH200 stainless steel sanitary double-seal mix proof valve possesses a single valve disc with two seals. It is used to isolate one medium from another in a pipe system. As an economical type among double-seat valves, the chamber between seals is joined to the two drain valves, through which the seals can be detected to avoid leak and the body can be cleaned.

Technical Parameters

1. Material pressure range: 0~8bar

2. Temperature range: -10℃~ 150℃

3. Operative air pressure: 6~8bar

Materials

1. Contact surface between the product and medium: 304 or 316L

2. Seal: Standard: EPDM

Optional: Silica gel or fluorine gel

Surface Finish of FH200 Sanitary Double-seal Mix Proof Valve

1. Outside: Sandblasting: Ra≤1.6 mm

Matt Polishing: Ra≤0.6 mm

2. Inside: Polishing: Ra≤0.6 mm

Requirements for Compressed Air Quality The Actuator Needs

1. Compressed air connection: Air tube equipped with air hose coupling R1/8"

2. Maximum particle size: 0.01mm

3. Maximum oil content: 0.08ppm

4. Dew point: ≤-10℃

5. Maximum water content: 7.5g/kg

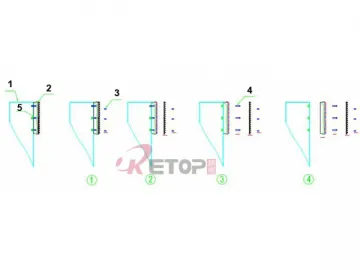

Among these series of sanitary mix proof valves, there is a common combination of reducing mix proof valves. The targeted design that the upper and lower chambers can have different diameters is conducive to combination and switching. The products have the same mix proof function and no liquid or gas remains.

Related Names

Fluid Separating Valve Manufacturer | Material Handling Products | Fluid Delivery System Parts

Links:https://globefindpro.com/products/82747.html