Carton Flow Racking/ Pallet Flow Racking

Our carton flow racking relies on the roller to transport goods from the loading end to the retrieval end. Between the front beam and the rear beam of each level of racking, the aluminum alloy or sheet metal roller is placed and inclined at a certain angle.

Goods are usually packed in a carton, or put into a plastic box. They are carried by a small vehicle, and conveniently stored and retrieved by manual handling. Each level of the rack unit can offer approximately 1,000kg of load bearing capacity. The racking height is below 2.5m.

This pallet flow racking is ideal for the conversion of working procedure on both sides of the assembly line, as well as the picking operation of distribution center, among other places. Coordinated with electronic tag, it can realize the information management of goods.

More Detailed Description

1. Our carton flow racking utilizes one aisle for loading and the other one for retrieval. Goods are placed on the roller.

2. Under the force of gravity, they will automatically decline from the on-load face to the retrieval face.

3. This racking can realize the first-in, first-out operation, providing low operational costs, fast storage speed, and high density. Also, it can achieve one-time replenishment and several-time picking.

4. Owing to its high storage efficiency, the carton flow racking can be used for the rapid storage of items in large quantities.

5. This product gives wide applications in supermarkets, pharmaceutical, chemical industry, electronics, logistics distribution center, publishing houses, and the factories with high degree of automation, among other industries.

6. In addition to this product, our company can also make a customized product in line with customer requirement.

Related Names

Industrial Racking Systems | Gravity Shelving | Warehouse Storage System

Links:https://globefindpro.com/products/83568.html

-

Multi-Tier Shelving System

Multi-Tier Shelving System

-

Shuttle Racking

Shuttle Racking

-

T Post Shelving

T Post Shelving

-

Asphalt Pavement Maintenance Truck

Asphalt Pavement Maintenance Truck

-

Cantilever Racking Upright

Cantilever Racking Upright

-

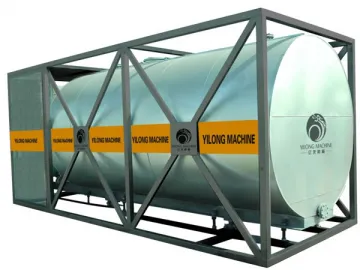

Rubber Bitumen Production Plant

Rubber Bitumen Production Plant

-

Bitumen Distributor

Bitumen Distributor

-

Gravity Racking

Gravity Racking

-

Dust Collector for Captive Shot Blasting Machine

Dust Collector for Captive Shot Blasting Machine

-

Longspan Shelving

Longspan Shelving

-

Spreader Box for Slurry Seal

Spreader Box for Slurry Seal

-

Automatic Light Duty Shelving

Automatic Light Duty Shelving