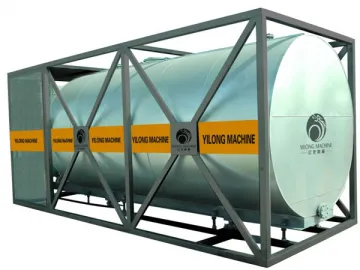

Rubber Bitumen Production Plant

We have deeply investigated the working principles and structural features of a large number of rubber bitumen manufacturing machines, and have obtained specialized knowledge of working process and developing trend of such a product. Then, our rubber bitumen production plant comes into existence successfully.

Our rubberized asphalt production system adopts modular structure which makes it compatible with other machines. It can work with conducting oil furnace, generator group, and base bitumen tank to form a complete production line.

Performance Features

1. The heating process of base bitumen is accomplished with the help of a large-capacity heat exchanger, and the temperature is electronically regulated to achieve different values as requested by actual applications.

2. The crumb rubber is weighed by an electronic scale. It is fed by a spiral converter at an adjustable speed.

3. The supplement of base bitumen is controlled by a variable frequency pump, and it is detected by flowmeter and weightometer.

4. This bitumen production plant is electrically driven, and the total power is 48kW.

5. The pump, which is specially designed for rubber bitumen, is imported from USA, and it offers better performance with longer service life.

6. The imported ceramic bearing and Siemens motor build up a high speed hybrid shearing system. As a result, uniform and reliable mixing is achieved.

7. The electrical components are supplied by leading manufacturers in the world, including ABB, Schneider, and others. Thus, the reliability and universality are improved greatly.

8. The weighing system adopts MCELL sensors and meters that are made in the USA, ensuring reliable and precise measurement.

9. The industrial control computer and PLC work together for the purpose of automatic control and manual control. So, reliable and convenient control is obtained. The human machine conversation interface makes the control of rubber bitumen manufacturing equipment more user-friendly.

10. Our bitumen production plant allows simple assembly and transportation owing to the modular structure.

Technical Parameters

| Model | AR150 (AR50, AR100) |

| Max. production capacity | 15 (5, 10) t/h |

| Rubber content | Adjustable within 15%-22% |

| Hopper volume for rubber | 0.3m3 |

| Rubber feeding mode | Spiral |

| Metering error for bitumen and rubber | ≤0.5% |

| Standard configuration | One main machine, and one reaction kettle |

| Overall dimensions for main machine (L×W×H) | 6090 × 2440 × 2700 mm |

| Reaction kettle volume | 15m3 |

| Heating area of heat conduction oil disk in reaction kettle | 35m2 |

| Overall dimensions for reaction kettle (L×W×H) | 6090 × 2440 × 2700 mm |

Advantages

This rubber bitumen production plant can work at different places, and user will find it really easy to move this machine to other sites. Meanwhile, this asphalt rubber production equipment introduces many new techniques, while the high-power heat conduction oil furnace and large-area heat exchanger fully satisfy the national standard of China. More details are listed below.

1. The proportion of rubber and bitumen can be set at any time according to customer needs, and the output is adjustable within maximum production capacity.

2. The weighing system shows a high precision level of 2%.

3. The rapid heating speed and good thermal insulation property are beneficial to the reactions of raw materials, and the high mixing efficiency is meaningful for the mixing stage as well as storage.

4. There is a powerful homogenizing device inside the tank to avoid segregation and sedimentation, so uniform swelling is gained.

5. The heat transfer oil is applied to achieve safe and rapid heating. It shows an outstanding heating speed which can reach up to 10-15℃/h, and the warm-up time is cut down.

6. The application of insulating layer guarantees that the static thermal insulation index will not exceed 12℃/8h.

7. The stainless steel frame endows our rubber bitumen production plant with excellent corrosion resistance and long service life.

Production Flow for Rubber Bitumen

Links:https://globefindpro.com/products/83575.html

-

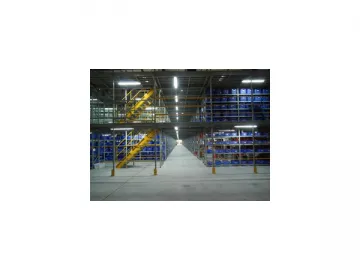

Drive-In Pallet Racking

Drive-In Pallet Racking

-

F28 Leather Comfort Sofa

F28 Leather Comfort Sofa

-

Chip Spreader

Chip Spreader

-

Selective Pallet Racking Beam

Selective Pallet Racking Beam

-

Cantilever Racking

Cantilever Racking

-

F2010 Italian Design Leather Sofa

F2010 Italian Design Leather Sofa

-

Cantilever Racking Upright

Cantilever Racking Upright

-

Asphalt Pavement Maintenance Truck

Asphalt Pavement Maintenance Truck

-

T Post Shelving

T Post Shelving

-

Shuttle Racking

Shuttle Racking

-

Multi-Tier Shelving System

Multi-Tier Shelving System

-

Carton Flow Racking/ Pallet Flow Racking

Carton Flow Racking/ Pallet Flow Racking