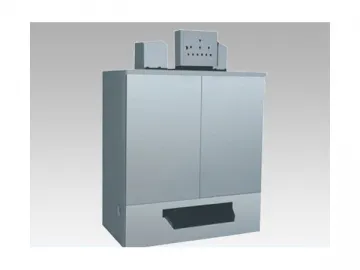

YH-IIB Vertical Form Fill Seal Machine

The YH-IIB vertical form fill seal machine is an automatic packaging system used for volumetric filling and packaging of liquids such as soy sauce, vinegar, liquor, milk, etc. in food and beverage processing industries.

Features

1. The fully enclosed structure design provides the liquid processing equipment with highly guaranteed hygienic standard. Pneumatic operation, coupled with computerized speed control, makes the liquid filling machine highly efficient.

2. The automatic vertical form fill seal machine employs a single cam driving mechanism and a special heat sealing system, which ensures uniform pressure, convenient operation, and simple maintenance.

3. User friendly design makes the liquid packaging equipment compatible with various types of laminate material, including multi-layer laminated type, oxygen resistant type, high temperature resistant type, and high-pressure PE type.

4. The vertical form fill seal machine has three-side sealing, back sealing, and four-side sealing functions. The heat sealing temperature is accurately controlled by an intelligent microcomputer control panel.

5. The packaging material unwinding and delivering system is controlled by a touch screen computer to offer high precision. Photoelectric tracing makes sure the printed patterns on packages are complete and beautiful. Additionally, the liquid filling system supports presetting, displaying, and adjusting the total length of packaging film.

6. The vertical form fill seal machine is available with two date printing methods: the carbon ribbon printing and metal letter stamping.

Technical Parameters| Power | 1kw |

| Power supply | 380V N/220V |

| Production speed | 25-45 bags/mins |

| Packing capacity | 100-500 ml / bag |

| Filling mode | Constant pressure filling |

| Filling preciseness | ± 1.5% |

| Pneumatic driver | 0.2-0.3m3/min, 0.6-0.8Mpa |

| Weight | 400 kg |

| Dimensions | 860× 800× 2600mm(L× W× H) |

Links:https://globefindpro.com/products/83845.html

-

Solid Ca-Zn PVC Stabilizer

Solid Ca-Zn PVC Stabilizer

-

Aseptic Filling Line for Milk

Aseptic Filling Line for Milk

-

Gabion Cage

Gabion Cage

-

Welded Wire Mesh Panel

Welded Wire Mesh Panel

-

YHBBJ-B Automatic Liquid Filling and Sealing Machine

YHBBJ-B Automatic Liquid Filling and Sealing Machine

-

Aseptic Vertical Form Fill Seal Machine for Cartons

Aseptic Vertical Form Fill Seal Machine for Cartons

-

ZB-I Aseptic Vertical Form Fill Seal Machine for Pillow Packs

ZB-I Aseptic Vertical Form Fill Seal Machine for Pillow Packs

-

Laboratory HTST/UHT Pilot Plant

Laboratory HTST/UHT Pilot Plant

-

Stainless Steel Wire Mesh

Stainless Steel Wire Mesh

-

Flake Ice Making Machine

Flake Ice Making Machine

-

Uncoated Steel Welded Pipe

Uncoated Steel Welded Pipe

-

Black Annealed Wire

Black Annealed Wire