Aseptic Vertical Form Fill Seal Machine for Cartons

The aseptic vertical form fill seal machine is designed to form, fill, and seal of aseptic cartons. It was developed and improved on basis of many years’ research, and combines the advantages of popular carton filling machines on national and international markets.

The aseptic processing equipment is scientific in structural design, easy in handle, nice in appearance, precise in metering, stable in performance and convenient in maintenance. By contrast, among many liquid packaging machines with the similar price, our aseptic vertical form fill seal machine has the highest output efficiency.

This aseptic filling line adopts the pneumatic transmission system to enhance reliability. Its employment of PLC control system and touch screen human machine interface allows for automatic completion of steps from packaging material sterilization, drying, aseptic carton forming, aseptic filling, filling volume control, sealing, to end product output.

Due to above advantages, our range of aseptic vertical form fill seal machine is widely used in food and beverage industries for aseptic processing of milk, soy milk, peanut milk, and fruit juice.

Construction

The aseptic processing and packaging system is made up of the electrical control system, light box, air sterilization system, membrane stretching mechanism, liquid filling system, and aseptic carton making system.

| Packing speed | 4200bags/h |

| Packing capacity | 250ml±2% |

| Power | 10KW |

| Power supply | 380V/50Hz |

| Compressed air consumption | 2M3/min(0.8Mpa) |

| Weight | 3200Kg |

| Dimensions | 3800X1500X3850mm |

| Packing material | Aluminum laminated membraneWidth: 188mmDiameter of membrane roll ≤1100mm |

Links:https://globefindpro.com/products/83851.html

-

YHBBJ-A Automatic Liquid Filling and Sealing Machine

YHBBJ-A Automatic Liquid Filling and Sealing Machine

-

Galvanized Steel Wire

Galvanized Steel Wire

-

YH-Ⅲ Aseptic Vertical Form Fill Seal Machine for Pillow Packs

YH-Ⅲ Aseptic Vertical Form Fill Seal Machine for Pillow Packs

-

YHGZFJ-A-4 Liquid Filling Machine

YHGZFJ-A-4 Liquid Filling Machine

-

Belt Conveyor

Belt Conveyor

-

Reinforced Pipe

Reinforced Pipe

-

YHBBJ-B Automatic Liquid Filling and Sealing Machine

YHBBJ-B Automatic Liquid Filling and Sealing Machine

-

Welded Wire Mesh Panel

Welded Wire Mesh Panel

-

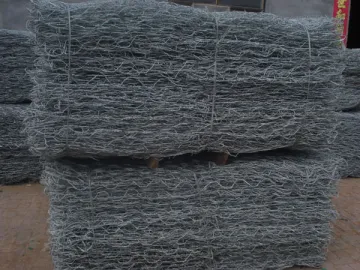

Gabion Cage

Gabion Cage

-

Aseptic Filling Line for Milk

Aseptic Filling Line for Milk

-

Solid Ca-Zn PVC Stabilizer

Solid Ca-Zn PVC Stabilizer

-

YH-IIB Vertical Form Fill Seal Machine

YH-IIB Vertical Form Fill Seal Machine