Track Chain

Caterpillar E200B

Kobelco SK120

Hyundai R200

Our range of track chain products are designed with the same specifications as the OEM parts. They are ideal replacement of original excavator and bulldozer parts as well as crawler heavy equipment parts for major brands such as Komatsu, Caterpillar, Hitachi, Kebelco, Hyundai, Kato, Daewoo, and Volvo.

The sealed and pre-lubricated track chain is especially designed to increase the assembly security of pins and bushings. The link plates are connected by pins and bushings with thickened wearing-resistant layer. Meanwhile, the exclusive heat treatment makes sure all our excavator track chains and bulldozer track chains have uniform surface hardness, precision controlled hardening depth, optimized core layer hardness as well. Thus, this selection of undercarriage components has long lifespan even utilized under highly corrosive conditions.

For enhanced reliability, the pin and bushing sizes are accurately matched during production. This is favorable for improving durability, abrasion resistance, and tensile strength, thus extending the service life of the track link assembly. Enlarged pins and bushings increase the wear life of the track chain as well.

More details are illustrated below.

1. All the link plates for our track chains are forged using 40Mn2 which is proven to have hardenability by CJMC. They are also quenched and tempered to ensure the strength, improve wear life, and optimize the hardness of core layer. The final tempering process effectively reduces the chance of link plate breakage and deformation even under heavy duty conditions.

2. Aside from link plates, the pins and bushings also undergo special induction heating to achieve international level surface hardness. Meanwhile, the track chain bushings undergo high-temperature carburizing, and the pins are deep-hardened to offer the best abrasion resistance and fatigue resistance. These are the reasons why our track parts have great durability and competence under various terrain conditions.

3. The PU seals protect the track chain from damages caused by reduced lubrication degree, dust particles, etc. Thus, long lifespan is further ensured.

4. Induction heating treatment offers maximum surface hardness up to HRC55.

Chain Components Hardness Distribution

Parameters of the Track Chain

| Material | 40Mn2 |

| Finish | Smooth and pretty |

| Colors | Black, yellow or any other customized color |

| Technique | Forging, Precise machining |

| Surface Hardness | HRC47-55, Depth: 5mm-8mm |

| Warranty Time | 1800hours/8months |

| Certification | ISO9001-9002 |

| MOQ | Unlimited |

| Delivery Time | Within 30 days after order confirmation or depend on order quantity |

Available Track Chain Models

| Models for Excavators | Models for Bulldozers | |||

| KOMATSU | CATERPILLAR | HITACHI | SUMITOMO | CATERPILLAR |

| PC60-5 | E200B | EX03 | SH120 | D3C |

| PC60-6 | KOBELCO | EX120 | SH200 | D5B |

| PC100-5 | SK120/SK200 | EX200-1 | SH280 | D65E-12 |

| PC200-3 | HYUNDAI | EX200-2 | KATO | KOMATSU |

| PC200-5 | R200 | EX200-3 | HD250 | D20 |

| PC300-1/2 | R220-5 | EX200-5 | HD700 | D30 |

| PC300-3/5 | DAEWOO | EX300-2 | HD770 | D31 |

| PC300-6 | DH220-5 | EX300-3 | HD820 | D60 |

Our company has 20 years experience in manufacturing all kinds of excavator and bulldozer spare parts, including not only the track chain, but also sprocket, track roller, top roller, idler assembly, and more. Hydraulic cylinders are available as well. If you need any type of excavator and bulldozer undercarriage parts, please feel free to contact us.

Links:https://globefindpro.com/products/85094.html

-

Other LED Crystal Ceiling Light

Other LED Crystal Ceiling Light

-

Integrated LED Track Light

Integrated LED Track Light

-

Round Base LED Crystal Ceiling Light

Round Base LED Crystal Ceiling Light

-

Four Cylinder Diesel Engine

Four Cylinder Diesel Engine

-

Fin Cooled Aluminum LED High Bay Light

Fin Cooled Aluminum LED High Bay Light

-

Outdoor LED Display Screen

Outdoor LED Display Screen

-

Two Cylinder Diesel Engine

Two Cylinder Diesel Engine

-

Six Cylinder Diesel Engine

Six Cylinder Diesel Engine

-

LED Crystal Chandelier

LED Crystal Chandelier

-

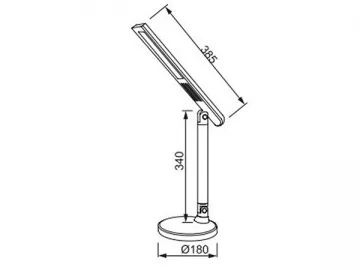

ABS LED Desk Lamp

ABS LED Desk Lamp

-

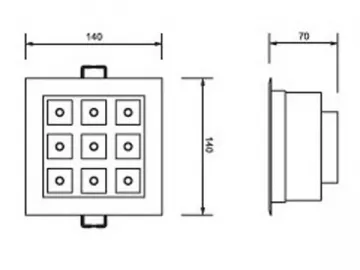

Multi-head LED Grille Light

Multi-head LED Grille Light

-

Gas Generator Set

Gas Generator Set