Top Roller

Komatsu D60

Caterpillar E200B

Hitachi EX300

Sumitomo SH300

Kato HD700

Daewoo DH280-3

Kobelco SK60

The top roller is also commonly called as the carrier roller. It is a type of undercarriage part for crawler engineering vehicles, including the bulldozer, excavator, paver, rotary drilling rig, and so on. We can offer top rollers for a great number of major heavy equipment brands, such as Caterpillar, Komatsu, Hitachi, Sumitomo, Kobelco, Hyundai, Kato, and Daewoo.

Features

As a line of commonly used heavy equipment parts, the top roller is forged using 50Mn material to provide high strength and abrasion resistance. Welded using friction welding technique, it is provided with extended operation life.

Meanwhile, our top rollers are heat treated via induction method to attain desired hardness level which is preset by our qualified engineers. Due to optimized hardness, they offer maximized wearing resistance while operating in all terrain conditions.

The roller shafts are forged and precision machined, and are also tempered and induction heated. Therefore, the line of construction equipment spare parts deliver high precision and outstanding abrasion resistance.

Construction of Top RollersHardness Distribution Drawing

Construction Features

1. Due to elaborate gap design, the wearing surface is enabled uniform and thorough internal lubricating.

2. Double-layer bushing is available for our top rollers. The external steel housing acts to prevent deformation even under heavy duty operations, by maximally support the pressure.

3. While improving wearing resistance, the specialized heat treatment for top rollers also ensures accurate depth of hardening. The well designed supporting structure is effective in avoiding roller cracks or breakage.

4. Heat treated roller shafts deliver high surface hardness. This, coupled with standardized processing procedures, makes sure the top roller shaft have long service life.

Parameters of Top Rollers

| Material | 50Mn |

| Finish | Smooth and pretty |

| Colors | Black, yellow, or customized colors |

| Technique | Forging, Precise machining, Robot welding, Friction welding |

| Surface Hardness | HRC50-56, Depth: 5mm-8mm |

| Warranty Time | 3500hours/14months |

| Certification | ISO9001-9002 |

| MOQ | Unlimited |

| Delivery Time | Within 30 days after order confirmation or depend on the order quantity |

Available Top Roller Models

| Carrier Roller Models for Excavators | Carrier Roller Models for Bulldozers | |||

| KOMATSU | CATERPILLAR | HITACHI | SUMITOMO | CATERPILLAR |

| PC40 | E120B | EX60 | SH120 | D4D |

| PC60 | E110B | EX100-1 | SH200 | D4C |

| PC60-5 | E311B | EX100-2 | SH280 | D4E |

| PC60-6 | E312B | EX100-3 | LS2800FJ1 | D5 |

| PC60-7 | E180 | EX100-5 | LS2800FJ2 | D5B |

| PC60L-5 | E240 | EX100M | SH220 | D6D |

| PC80-1 | CAT215 | EX120-1 | SH300 | D7G |

| PC80-3 | CAT225 | EX120-2 | DAEWOO | D80A-7 |

| PC90-1 | CAT235 | EX120-3 | DH07 | KOMATSU |

| PC100-2 | E200B | EX120-5 | DH08 | D20 |

| PC100-3 | E320 | EX150 | DH180 | D30 |

| PC100-5 | E300 | EX200-1 | DH220-3 | D31 |

| PC120-3 | CAT330 | EX200-2 | DH220-5 | D40 |

| PC120-5 | KOBELCO | EX200-3 | UH081 | D45 |

| PC120-6 | SK07 | EX220 | DH250 | D50 |

| PC200-2/3/5 | SK21 | EX220-2/3 | DH280-3 | D53 |

| PC200-6 | SK60 | EX270 | DH300-5 | D55 |

| PC200-7 | SK60M-3 | EX300 | DH320 | D57 |

| PC200-8 | SK60M-5 | EX300-1 | DH330-3 | D60-3 |

| PC200LC-1 | SK100 | EX400-1/2/3 | KATO | D60 |

| PC200LC-3/5/6 | SK120 | EX400-5 | HD700 | D65 |

| PC200LC-7 | SK150M | EX450-5 | HD770 | D75 |

| PC240-3/5 | SK200 | HYUNDAI | HD250 | D80 |

| PC300-1/2/5 | SK220 | R200 | DH1250 | D85 |

| PC300-6 | SK200-6 | R220-3 | VOLVO | D155 |

| PC400 | SK300 | R220-5 | EC210 | |

| PC400-7 | SK330 | R290 | EC290 | |

Undercarriage Parts by Brand

Links:https://globefindpro.com/products/85107.html

-

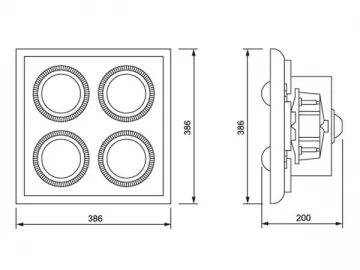

Double Head LED Grille Light

Double Head LED Grille Light

-

Tower Shape LED Crystal Ceiling Light

Tower Shape LED Crystal Ceiling Light

-

LED Explosion Proof Light with Die-Casting Aluminum Housing

LED Explosion Proof Light with Die-Casting Aluminum Housing

-

Aluminum LED High Bay Light

Aluminum LED High Bay Light

-

Square Base LED Crystal Ceiling Light

Square Base LED Crystal Ceiling Light

-

Integrated LED High Bay Light without Lampshade

Integrated LED High Bay Light without Lampshade

-

Track Roller

Track Roller

-

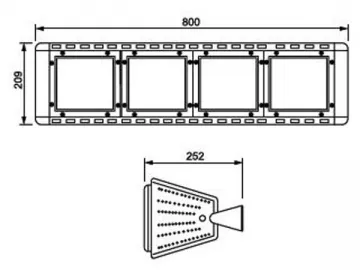

Single Head LED Grille Light

Single Head LED Grille Light

-

High Power LED Tunnel Light

High Power LED Tunnel Light

-

Indoor LED Display Screen

Indoor LED Display Screen

-

Outdoor LED Display Screen

Outdoor LED Display Screen

-

Fin Cooled Aluminum LED High Bay Light

Fin Cooled Aluminum LED High Bay Light