QT5-20A3 Concrete Block Making Machine

This QT5-20A3 concrete block making machine is used to make color floor tiles, hollow blocks, and other types of concrete products. The wall panels or floor tiles need no drying, and can be stacked directly, thus saving labor intensity. This machine is suitable for the clients who require medium yield.

Product Instruction

1. This equipment is a four-pillar jolt-squeeze molding brick making machine, which can make several blocks per time. In this regard, it decreases electricity consumption and lowers labor cost.

2. It realizes automatic plate feeding, plate discharging, and aggregate vibration. The concrete blocks made by this machine each time, can be transported and stacked together.

3. This QT5-20A3 concrete block making machine is multifunctional. Its mold can be freely changed with ease.

4. It needs only 10 pallets. The concrete wall panel or floor tile made by our machine can be stacked without being dried.

5. The machine uses the special chasises, all of which are easily installed and debugged. Those chasises lower the failure rate.

6. The upper suspension type rail mounted charging wagon is used to decrease the system pressure.

7. The air-bag type mold clamping method is used for the die installation.

Parameters

| Supporting Plate Size | 1150*580*25mm |

| Forming Cycle | 20~25 seconds per time (Different product has different forming time)(Surface materials is excluded) |

| Product Height | 50~200mm |

| Forming Area | 1, 100x500mm |

| Operating System | Semi-automatic (The system can be updated to be the full automatic type) |

| Total Installed Capacity | 20.7Kw |

| Overall Dimensions | 6923x2100x2500mm |

| Weight | 7500kg |

| Floor Space | Block making machine with a rear conveyor: L*W*H 17.5m*4m*2.6m |

| Maxi. Pressure | 5t |

| Workers | 8-10 people (semi-automatic); 4 people (full-automatic, stacker crane and forklift are equipped) |

| Forming Method | Pressure and vibration |

| Output | 100 m3 (Mini. Output per 8 hours) 390*190*190mm |

| Executive Standard | JC/920-2011 Architecture material industry concrete block machine. |

Standard Configuration

Primary machine unit, pump station, surface material drawer, ash bucket with silo, pallets feeder, bricks conveyor, conveyor, tool box, accessories, 20 pieces of 1150*580*25bamboo plywood, operation instruction, warranty card, product delivery form, 4 trolleys, one set of 100*200 floor tile mold.

Remark

Raw Materials: Construction waste, coal ash, river sand, cement, stones, slag

Output per Shift

Standard Blocks: 60,000 pieces of 238*51*115 blocks per 8 to 10 hours.

Hollow blocks: 120m3

Floor Tile: 600m2

Advantages

| 1. Four-direction Positioning Aggregate Drawer | |

| Our QT5-20A3 concrete block making machine applies the four-direction positioning aggregate drawer. This drawer operates stably, thus reducing the system pressure. | |

| 2. Chassis Integrated Design | |

| The chassis integrated design well combines the host machine, aggregate drawer, and surface materials drawer. For that reason, the concrete block maker operates stably. | |

| 3. External Motors | |

| The machine applies two external motors, both of which can be conveniently maintained and have good heat dissipation. | |

| 4. Surface Materials Drawer of Special Design | |

| The surface materials drawer can be opened from one side, thus providing convenience for the mold replacement. | |

| 5. Hydraulic Motor | |

| Our automatic concrete block forming machine is driven by the hydraulic motor. Both vibrational frequency and vibration time can be adjusted according to different blocks. | |

| 6. Rubber Block for Mold Connecting | |

| The mold is connected to the equipment with a rubber block, which can increase the exciting force while decreasing the vibration energy loss. | |

| 7. Thickened Guide Pillar | |

| The thickened guide pillar has significantly increased the stability and balance of the equipment. | |

| 8. Lock Sleeve for Adjusting Lower Mold Height | |

| When installing different mold, you can adjust the lower mold height with the lock sleeve on the guide pillar. | |

| 9. PLC Control | |

| This concrete block maker is PLC controlled. You can choose the program according to the block type. The program will be displayed via the touch screen. | |

| 10. Duplex Impeller Pump | |

| The pump station has a duplex impeller pump which is more powerful than the ordinary oil pump. | |

| 11. Oil Immersed Vibroramme | |

| Since the vibrorammer is oil immersed, you don’t have to add oil during per shift. Outside the block making machine, an oil can is installed to show the oil amount. | |

| 12. T-shaped Shifting Fork for Materials Distribution | |

| The T-shaped shifting fork makes material distribution uniform and compact all the more. | |

Finished Product

| Interlocking Grass Planting Brick with Round Holes | Large Red Pavement Tile | Arc Block |

Related Names

Grass Block Machine | Large Paver Brick Equipment | Water Well Brick Maker

Links:https://globefindpro.com/products/85541.html

-

BTS Series

BTS Series

-

QT4-20A2 Concrete Block Making Machine

QT4-20A2 Concrete Block Making Machine

-

Professional Series

Professional Series

-

All Season Series

All Season Series

-

QT5-20B3 Concrete Block Making Machine

QT5-20B3 Concrete Block Making Machine

-

PF Pro Series

PF Pro Series

-

QWT21 Automatic Concrete Block Production Line

QWT21 Automatic Concrete Block Production Line

-

Pool Maintenance Kits

Pool Maintenance Kits

-

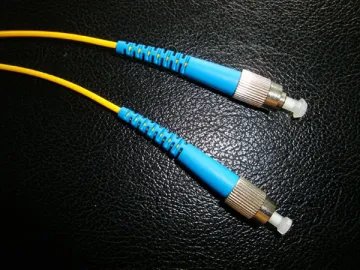

FC Fiber Optic Patch Cord

FC Fiber Optic Patch Cord

-

Pool Disinfection and Test Kit

Pool Disinfection and Test Kit

-

Dark Blue Pool Parts

Dark Blue Pool Parts

-

Swimming Pool Ladders

Swimming Pool Ladders