QT5-20B3 Concrete Block Making Machine

Our QT5-20B3 concrete block making machine can make all kinds of concrete products including color floor tiles, hollow blocks, etc. It realizes automatic plate feeding, plate discharging, and aggregate vibration. This machine is the preferred choice for concrete kerb stone manufacturing.

Product Instruction

1. The QT5-20B3 concrete block making machine is a four-pillar jolt-squeeze molding brick making machine that can produce kerb stones.

2. It forms several concrete products per time, decreasing the electricity consumption and labor cost. Also, those concrete products can be transported and stacked in one time, thus improving the production efficiency.

3. Its mold can be arbitrarily replaced for making different concrete products. The concrete product made by this machine has the maximum height of 500mm.

4. The air-bag type mold clamping method is used for the die installation.

5. The upper suspension type rail mounted charging wagon is used to decrease the system pressure.

Parameters

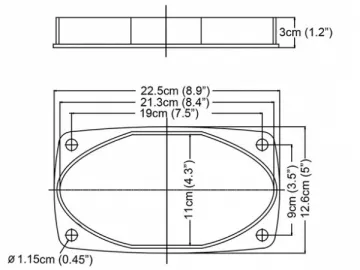

| Supporting Plate Size | 1,150×580×35 (mm) |

| Product Height | 250-500 (mm) |

| Molding Area | 1,100×500 (mm) |

| Operating System | Semi-automatic |

| Installed Capacity (Total Power) | 35.99kw |

| Weight | About 8644kg |

| Overall Dimensions | 6, 923×2, 569×4, 525 (mm) |

| Number of Operators | 4 people Equipped with palletizer and forklift |

| Power Supply Method | Pressure and Vibration |

| Installation and Debugging Cycle | 4-5 days (when the foundation is ready-made) |

Standard Configuration

Primary machine unit, pump station, electrical cabinet, surface material drawer, ash bucket with silo, pallets feeder, bricks conveyor, conveyor, tool box, accessories, 20 pieces of 1150*580*25 bamboo plywood, operation instruction, warranty card, product delivery form, 4 handcarts.

Finished Product

Related Names

Brick Curb Making Machine | Decorative Brick Maker | Kerbstone Machine

Links:https://globefindpro.com/products/85547.html

-

PF Pro Series

PF Pro Series

-

BTS-C Series

BTS-C Series

-

PVC Solar Pool Shower

PVC Solar Pool Shower

-

European Style Series

European Style Series

-

Mould of Concrete Block Molding Machine

Mould of Concrete Block Molding Machine

-

Aluminum Outdoor Solar Shower

Aluminum Outdoor Solar Shower

-

All Season Series

All Season Series

-

Professional Series

Professional Series

-

QT4-20A2 Concrete Block Making Machine

QT4-20A2 Concrete Block Making Machine

-

BTS Series

BTS Series

-

QT5-20A3 Concrete Block Making Machine

QT5-20A3 Concrete Block Making Machine

-

QWT21 Automatic Concrete Block Production Line

QWT21 Automatic Concrete Block Production Line