API Seamless Line Pipe

The API seamless line pipe is used to transfer oil, gas or water to the industrial end users. The linepipe takes two forms, seamless or with seams. It often goes through special machining process to receive a threaded, shouldered or plain end. For joining methods, the linepipe can be butt welded, threaded, or socket welded.

Our API seamless line pipe specifically refers to the pipe that has been tested to and complies with the specification API 5L. API linepipe-making process is similar to that of the ordinary seamless steel pipe, but the former has more stringent precision and tolerance band requirements to meet. In order for a better understanding of our API 5L linepipe, we give the following detailed specification and order information for reference.

Specification: API SPEC 5L PSL1/PSL2

1. Process: hot rolling, cold drawing, hot-expanding

2. Standards: API 5L PSL1, PSL2

3. Specification Range:

OD: 3''-24'' (48mm-610mm)

WT: SCH10-SCHXXS

4. Materials: GR.B, L245, L290, L360, X42, X46, X56, X65, X70

5. Testing: eddy current, hydrostatic, ultrasonic, intergranular corrosion.

6 Packing: in bundles with steel strips, seaworthy packing as per customer's requirements

Tolerance

| Spec. | DIA | Thickness | ||||

| A25.A.B | X42-X70 | |||||

| D<60.3 | 0.41/-0.40mm | D<73 | 20/-12.5% | D≥73 | 15/-12.5% | |

| API SPEC 5L | D≥60.3 | 0.75/-0.40mm | D≥73 | 15/-12.5% | D>73 | 15/-12.5% |

Chemical Composition

| Spec. | Steel Grade | C | Mn | P | S | |

| Max. | Max. | Min. | Max. | Max. | ||

| API SPEC 5L | PSL1 ( GB/T9711.2) | |||||

| A25II | 0.21 | 0.6 | 0.03 | 0.03 | ||

| A25III | 0.21 | 0.6 | 0.45 | 0.8 | 0.03 | |

| A | 0.22 | 0.9 | 0.03 | 0.03 | ||

| B | 0.28 | 1.2 | 0.03 | 0.03 | ||

| X42 | 0.28 | 1.3 | 0.03 | 0.03 | ||

| X46.X52.X56 | 0.28 | 1.4 | 0.03 | 0.03 | ||

| X60.X65.X70 | 0.28 | 1.4 | 0.03 | 0.03 | ||

| PSL2 | ||||||

| B | 0.24 | 1.2 | 0.025 | 0.015 | ||

| X42 | 0.24 | 1.3 | 0.025 | 0.015 | ||

| X46.X52.X56 | 0.24 | 1.4 | 0.025 | 0.015 | ||

| X60.X65.X70.X80 | 0.24 | 1.4 | 0.025 | 0.015 | ||

Mechanical Properties

| Spec. | Steel Grade | Yield Strength (MPa ) | Tensile Strength (MPa ) | Elongation | ||

| API SPEC 5L | PSL1 ( GB/T9711.2) | |||||

| A25 | 172 | 310 | ||||

| A | 207 | 331 | ||||

| B | 241 | 414 | ||||

| X42 | 290 | 414 | ||||

| X46 | 317 | 434 | ||||

| X52 | 359 | 455 | ||||

| X56 | 386 | 490 | ||||

| X60 | 414 | 517 | ||||

| X65 | 448 | 531 | ||||

| X70 | 483 | 565 | ||||

| PSL2 | ||||||

| Min. | Max. | Min. | Max. | |||

| B | 241 | 448 | 414 | 758 | ||

| X42 | 290 | 496 | 414 | 758 | ||

| X46 | 317 | 524 | 434 | 758 | ||

| X52 | 359 | 531 | 455 | 758 | ||

| X56 | 386 | 544 | 490 | 758 | ||

| X60 | 414 | 565 | 517 | 758 | ||

| X65 | 448 | 600 | 531 | 758 | ||

| X70 | 483 | 621 | 565 | 758 | ||

| X80 | 552 | 690 | 621 | 827 | ||

As an experienced API 5L line pipe manufacturer based in China, we also provide other premium tubular products including the spiral-seam tube, corrosion-resistant tube, and pipe casing. Our product is commonly used to convey oil, gas, and water in petroleum and natural gas industries. It is also employed in the power station and reservoir. If you have any question about out API 5L, please contact us. We look forward to cooperation with you.

Related Names

Oil and Gas Pipe | Steel Pipeline | Seamless Oil Tubing

Links:https://globefindpro.com/products/86360.html

-

Engine Parts

Engine Parts

-

Komatsu Excavator Boom Arm

Komatsu Excavator Boom Arm

-

Cab Parts

Cab Parts

-

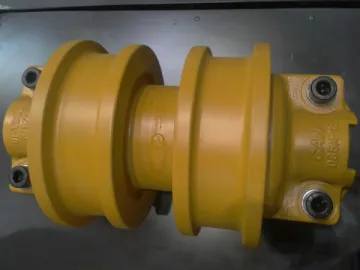

Shantui Bulldozer Carrier Roller

Shantui Bulldozer Carrier Roller

-

OCTG Pup Joint

OCTG Pup Joint

-

OCTG Couplings for Casing & Tubing

OCTG Couplings for Casing & Tubing

-

Komatsu Excavator Long Boom Arm

Komatsu Excavator Long Boom Arm

-

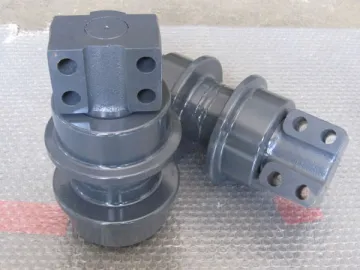

Komatsu Bulldozer Track Roller

Komatsu Bulldozer Track Roller

-

Komatsu Excavator Sprocket

Komatsu Excavator Sprocket

-

Komatsu Excavator Carrier Roller

Komatsu Excavator Carrier Roller

-

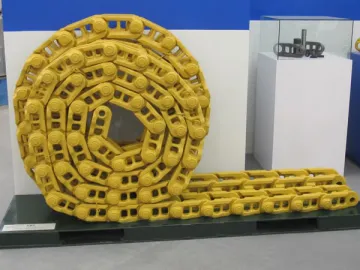

Komatsu Bulldozer Track Chain and Track Shoe

Komatsu Bulldozer Track Chain and Track Shoe

-

Komatsu Excavator Bucket

Komatsu Excavator Bucket