Automatic Feeding CO2 Laser Cutting Machine

Automatic Feeding CO2 Laser Cutting Machine

Our automatic feeding CO2 laser cutting machine could transfer the workpiece automatically to the station with the help of automatic feeding system. It is more suitable for large-scale processing. Our product could engrave workpiece with the largest size of 1600 * 1000mmm while the highest carving speed is 24000mm/min. The repeat accuracy of our product is quite high, in which the error is less than 0.1mm. The work efficiency is also quite high.

Our automatic feeding CO2 laser cutting machine should be stored in an environment at 0 to 45 degrees Celsius. Regular maintenance such as adding lubricants is also needed to extend its service life. Moreover, exhaust gas fan and cooling pump are also optional to help maintain a good working environment.

Technical Specification

Model | JCUT-1610 | ||||

Engraving Size | 1600 x 1000 | ||||

Laser Power | 60W, optional 80W | ||||

Engraving Speed | 0 - 24000mm/min | ||||

Repeat Accuracy | ±0.1mm | ||||

Power Supply | AC 220V ±10%, 50 - 60Hz | ||||

Power Consumption | <1,000W | ||||

Working Temp. | 0 - 45°C | ||||

Working Humidity | 8 - 95% | ||||

Min. Engraving Size for Texts | 1 x 1mm for letters, 2 x 2mm for Chinese Characters | ||||

Output File Format | BMP, HPGL, PLT, DST, DXP, and AI | ||||

Driven Method | Stepper driving | ||||

Cooling Method for Laser | Water-cooling or selected cooler | ||||

Work Bench | Lifting Bench | ||||

Other Auxiliary Equipment. | Exhaust gas fan and gas pump for cooling material | ||||

Laser Control Software | DSP Control System | ||||

Compatible Software | CorelDraw AutoCAD Photoshop | ||||

Laser Tube Type | CO2 Glass Laser Tube | ||||

Related Names

Auto Feeding Laser Cutting Machine | Auto Material Feeding Laser Cutting System

Links:https://globefindpro.com/products/87071.html

-

High Quality Steel Pipe Elbow

High Quality Steel Pipe Elbow

-

CNC Cylinder Engraving System

CNC Cylinder Engraving System

-

2U Stick Energy Saving Bulb

2U Stick Energy Saving Bulb

-

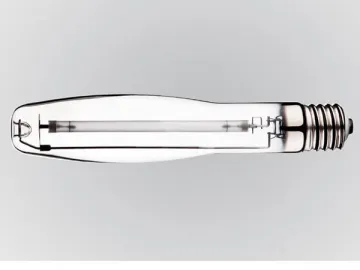

High Lumen Sodium Vapor Bulb

High Lumen Sodium Vapor Bulb

-

Printable Thermal Label

Printable Thermal Label

-

Coreless Thermal Paper Roll

Coreless Thermal Paper Roll

-

Steel Pipe Reducer

Steel Pipe Reducer

-

Steel Pipe Cap

Steel Pipe Cap

-

Jade Carving Samples

Jade Carving Samples

-

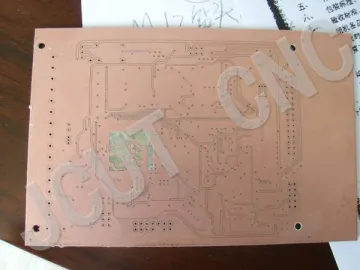

Printed Circuit Board Engraving Samples

Printed Circuit Board Engraving Samples

-

Cylindrical Engraving Samples

Cylindrical Engraving Samples

-

YAG Laser Cutting Machine

YAG Laser Cutting Machine