PE Spiral Corrugated Pipe Extrusion Line (200mm-3000mm)

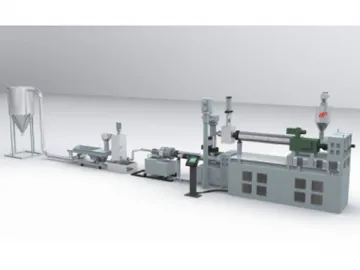

PE spiral corrugated pipe extrusion line is our self developed drainage pipe extrusion product that possesses independent intellectual property rights. The finished pipe diameter ranges from 200mm to 3000mm. This equipment requires low investment but features advanced production process.

Main Specifications

Model | Pipe Diameter Range (mm) | Extruder Model | Producing Speed of Line (m/h) | Max. Output (kg/h) | Total Installed Power (kVA) | Overall Dimension L×W×H |

FLBWG-800 | 300-800 | FSJ-65X33(2sets)FSJ-40X30(1sets) | 1-30 | 400 | 170 | 17×8×4.0 |

FLBWG-1600 | 600-1600 | FSJ-80X33(2sets)FSJ-40X30(1set) | 1-20 | 800 | 270 | 20×10×4.8 |

FLBWG-2000 | 800-2000 | FSJ-90X33(2sets)FSJ-50X33(1set) | 1-18 | 1200 | 350 | 22×12×5 |

FLBW-3000 | 1500-3000 | FSJ-100X33(2sets)FSJ-50X33(1set) | 1-10 | 1500 | 400 | 25×12×7 |

Detailed Technical Parameters

Inner Diameter (mm) | Ring Stiffness Class S2 | Weight (Class S2) (kg/m) | Length (m) |

200 | ≥8 | 3.6 | 6/12 |

300 | ≥8 | 5.6 | 6/12 |

400 | ≥8 | 9.8 | 6/12 |

500 | ≥8 | 12.8 | 6/12 |

600 | ≥8 | 16.8 | 6/12 |

700 | ≥8 | 22.8 | 6/12 |

800 | ≥8 | 26.0 | 6/12 |

900 | ≥8 | 37.0 | 6/12 |

1000 | ≥8 | 49.3 | 6/12 |

1200 | ≥8 | 68.0 | 6/12 |

1500 | ≥8 | 99.0 | 6/12 |

1600 | ≥8 | 118.0 | 6/12 |

1800 | ≥8 | 148.0 | 6/12 |

2000 | ≥8 | 166.0 | 6/12 |

2200 | ≥8 | 200.0 | 6/12 |

2500 | ≥8 | 300.0 | 6/12 |

2800 | ≥8 | 380.0 | 6/12 |

3000 | ≥8 | 450.0 | 6/12 |

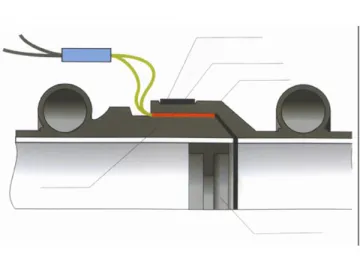

To achieve simple operation and high degree of automation, PE spiral corrugated pipe extrusion line utilizes a hot melt molding of inner and outer layers as well as the PLC industrial tablet personal computer automatic control system. In the molten state, a composite is formed by the inner layer of PE band and the outer layer of U tube. After spray cooling and forming, these two layers will be no longer separated, which can provide better adhesive effect than the double wall corrugated pipe.

Furthermore, the pipe produced by our PE spiral corrugated pipe extrusion line possesses light weight, flare connection, convenient construction and some others. It can be mostly found in urban sewerage and drainage. Also, it can be applicable to the production of PE new material or renewable raw material. The electromagnetic heating ring helps save 50% electricity and also makes the effective utilization of energy reach over 98%.

Send Message

Most Recent

Automatic Strapping Machines

packaging-strapping.com

Paper machine clothing for forming section in cardboard machinery

forming-dryerfabrics.com

Fully Automatic T-Shirt Bag Making Machine (200pcs/min×2)

plastic-bagmachines.com

Threaded Button Bits

rock-drillingtool.com

More

Ultra-High-Voltage Power Transformer (110kV-220kV)

electrical-transformers.com

Action Camera Suction Cup Mount, UBA-GO/G1

suctioncup-mount.com

Magnetic Coagulation and Sedimentation System

industrial-waterfilter.com

Electric Cargo Van 5.9 Meters

aucwell-ev.com

PVC Duct Tape

selfadhesive-tapes.com

MBB Cell Stringer Machine, AM050E

solarpanelline.com

Related products

ZC-180H Corrugated Pipe Extrusion Line

pipecorrugator.com

ZC-1000H Corrugated Pipe Extrusion Line

pipecorrugator.com

ZC-1500H Corrugated Pipe Extrusion Line

pipecorrugator.com

ZC-600H Corrugated Pipe Extrusion Line

pipecorrugator.com

ZC-1200H Corrugated Pipe Extrusion Line

pipecorrugator.com

ZC-2000H Corrugated Pipe Extrusion Line

pipecorrugator.com

Videos

PE/PPR Pipe Extrusion Line

UPVC Pipe Extrusion Line

Gas Polyethylene PE Pipe

PP/PE-based WPC Profile Extrusion Line

PE Cast Film Line

Co Extrusion Line

Links:https://globefindpro.com/products/87133.html

-

ANSI Coded High Pressure Sodium Vapor Lamp

ANSI Coded High Pressure Sodium Vapor Lamp

-

Metal Halide PAR Lamp

Metal Halide PAR Lamp

-

High Pressure Sodium Vapor Lamp With Internal Ignitor

High Pressure Sodium Vapor Lamp With Internal Ignitor

-

High Efficiency Three Stage PE/PP/PVC Pelletizing Line

High Efficiency Three Stage PE/PP/PVC Pelletizing Line

-

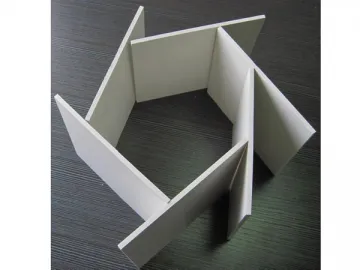

PVC Sheet Making Machine

PVC Sheet Making Machine

-

PVC Foam and WPC Board Production Machine

PVC Foam and WPC Board Production Machine

-

Electronic Ballast for Metal Halide Lamp

Electronic Ballast for Metal Halide Lamp

-

Colored Metal Halide Light Bulb

Colored Metal Halide Light Bulb

-

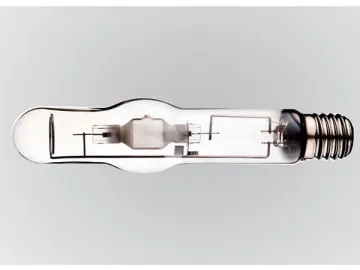

Pulse Start Metal Halide Bulb

Pulse Start Metal Halide Bulb

-

High Pressure Mercury Vapor Lamp

High Pressure Mercury Vapor Lamp

-

Probe Start Metal Halide Bulb

Probe Start Metal Halide Bulb

-

Road Lighting

Road Lighting