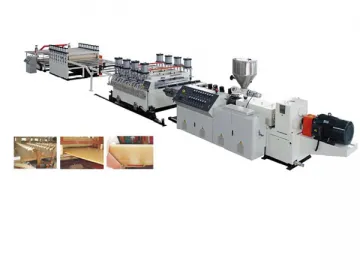

PVC Foam and WPC Board Production Machine

PVC Foam and WPC Board Production Machine

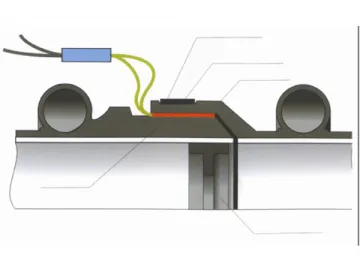

PVC foam and WPC board production machine can produce PVC foam board as well as wood and plastic composite board on the same production line. The line is formed by twin screw extruder, plate die, vacuum sizing platform, traction unit, cutting machine and stockpiling platform.

Our PVC foam and WPC board production machine can uniformly mix the PVC resin and wood powder, which can make the plasticizing effect full and the content of wood powder reach up to 50%. Its plate die and vacuum sizing platform ensure the even discharging material. The board surface is smooth. In addition, our product utilizes numerical control or PLC touch screen control system. All its electrical components come from such famous brands as Siemens, Schneider and some others, which can maintain the stable operation of our machine and simultaneously raise the yield of extruder. Through 38CrMOALA nitrogen treatment, both screw and screw barrel possess the thickness from 0.4mm to 0.7mm and the hardness of more than 940. The cutting machine is characterized by its accurate work of milling cutter, high precision cutting, as well as smooth cutting surface. The caterpillar tractor takes advantage of its precise frequency converter so as to effectively control the hauling speed.

Technical Parameters

Model | YF600 | YF800 | YF1000 | YF1250 |

Max. Width of Product (mm) | 600 | 800 | 1000 | 1250 |

Extruder Model | SJZ80/156 | SJZ80/156 | SJZ92/188 | SJZ92/188 |

Max. Extrusion Capacity (kg/h) | 360 | 360 | 600 | 600 |

Extruder Power (kW) | 55 | 55 | 110 | 132 |

Cooling Water (m3/h) | 12 | 13 | 15 | 18 |

Compressed Air (m3/min) | 0.5 | 0.6 | 0.8 | 1 |

Related Names

Heat Insulation Board Extrusion Machinery | Composite Board Making Machine

Links:https://globefindpro.com/products/87139.html

-

PE/PP Sheet Extrusion Machine

PE/PP Sheet Extrusion Machine

-

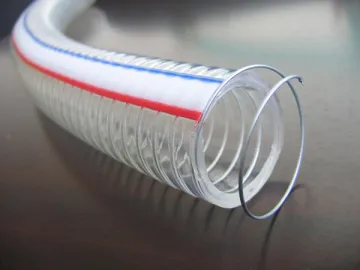

PVC Spiral Steel Wire Reinforced Hose Making Machine

PVC Spiral Steel Wire Reinforced Hose Making Machine

-

PVC Transparent Hose & Braided Fiber Reinforced Hose Extrusion Machine

PVC Transparent Hose & Braided Fiber Reinforced Hose Extrusion Machine

-

Plastic Mixer

Plastic Mixer

-

PMMA Pipe and Rod Extrusion Machine

PMMA Pipe and Rod Extrusion Machine

-

Single and Multilayer Plastic Mould for PVC/PE/PP Pipe

Single and Multilayer Plastic Mould for PVC/PE/PP Pipe

-

PVC Sheet Making Machine

PVC Sheet Making Machine

-

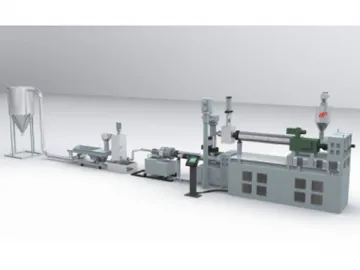

High Efficiency Three Stage PE/PP/PVC Pelletizing Line

High Efficiency Three Stage PE/PP/PVC Pelletizing Line

-

High Pressure Sodium Vapor Lamp With Internal Ignitor

High Pressure Sodium Vapor Lamp With Internal Ignitor

-

Metal Halide PAR Lamp

Metal Halide PAR Lamp

-

ANSI Coded High Pressure Sodium Vapor Lamp

ANSI Coded High Pressure Sodium Vapor Lamp

-

PE Spiral Corrugated Pipe Extrusion Line (200mm-3000mm)

PE Spiral Corrugated Pipe Extrusion Line (200mm-3000mm)