Steel Frame Shaker Screen

Steel Frame Shaker Screen

The steel frame shaker screen is often used for screening the drilling fluid. It is mainly composed of steel frame and 2 to 3 layers of stainless steel meshes. The steel frame is produced by welding high strength rectangular steel tube or flat steel. Meanwhile, several bars of stiffeners are available for structure supporting. The screen mesh can be linked with the frame through metal lining or adhered to the frame directly. We can offer the product with different dimensions to meet the needs of customers.

Technical Parameters

Brand and Model of Shaker | Mesh | Dimension (L×W×H) | Approx. Weight | Number of Layer | Screen Material | Frame Material |

MI-Swaco Mongoose | API 20 - API 400 | 1165×585×45mm | 12 kg | 2 or 3 | SS304 or SS316 | Carbon Steel |

MI-Swaco D380 | API 20 - API 400 | 1180×712×30mm | 14 kg | 2 or 3 | SS304 or SS316 | Carbon Steel |

NOV Brandt Cobra | API 20 - API 400 | 25×49.3125×1 inches | 34±1pound | 2 or 3 | SS304 or SS316 | Carbon Steel |

Brandt VSM300 Scalping Type | API 20 - API 400 | 37×26.625×1.5 inches | 12 kg | 2 or 3 | SS304 or SS316 | Carbon Steel |

Brandt VSM300 Primary Type | API 20 - API 400 | 35×27×1.5 inches | 11 kg | 2 or 3 | SS304 or SS316 | Carbon Steel |

Brandt VSM300 Secondary Type (Dryer Panel) | API 20 - API 400 | 8×27 inches | 4.3 kg | 2 or 3 | SS304 or SS316 | Carbon Steel |

Note: The table shows the detailed information of our steel frame shaker screens. The specific dimension and details can be adjusted according to the requirements of customers. The weight listed in the table is the average level of the product with the same model.

Features

1. Configured with high strength steel frame, stiffeners and screen mesh with moderate tension, the performance of the steel frame shaker screen is enhanced largely in strength, service lifetime and flow of drilling fluid that the product can bear.

2. The mesh numbers of the furnished screen meshes are different. Through combining the screen meshes correctly and appropriately, the screening effect can be improved greatly.

3. The wedged rapid tensioning device allows for more convenient installation of the product. The time for stopping the machine to replace the product can be saved.

4. The screen mesh is divided into a number of small independent meshes to avoid local damage and excessive expansion. Meanwhile, the special rubber is available for repairing damage, which can save time and reduce using cost.

Links:https://globefindpro.com/products/87540.html

-

H Beam Straightening Machine

H Beam Straightening Machine

-

Assembly, Welding and Straightening Combined Machine

Assembly, Welding and Straightening Combined Machine

-

Composite Material Shaker Screen

Composite Material Shaker Screen

-

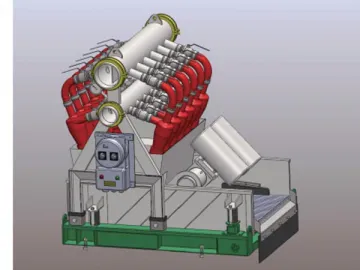

Mud Desilter

Mud Desilter

-

Pyramid Shale Shaker Screen

Pyramid Shale Shaker Screen

-

Mud Decanter Centrifuge

Mud Decanter Centrifuge

-

Conventional Welding Rotator

Conventional Welding Rotator

-

Submersible Slurry Pump

Submersible Slurry Pump

-

Mud Tank

Mud Tank

-

Mini Mud Cleaner

Mini Mud Cleaner

-

Single Screw Pump

Single Screw Pump

-

Welding Column & Boom

Welding Column & Boom