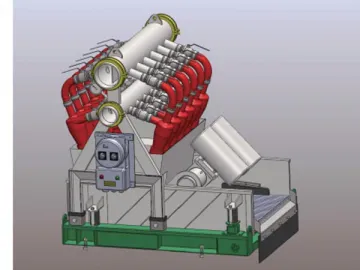

Conventional Welding Rotator

The conventional welding rotator is capable of adjusting the distance between centers of the rollers through the reserve screw hole or the screw to adapt to the changing diameters of the work piece. The product adopts dual motors drive with the cycloid pinwheel reducer or the worm and gear reducer. This product is mainly used for welding large containers.

Technical Parameters

| Model | Max. Load Weight(t) | Applicable Simple Structure Diameter(mm) | Roller Diameter and Width (mm) | Roller Line Speed(m/h) | Motor Power (kw) | Interval Adjustment Method | Speed Regulation Method | |

| Rubber Roller | Metal Roller | |||||||

| HGK5 | 5 | Φ250-2300 | Φ250×100 | 2×Φ240×20 | 6-60 | 2×0.37 | Manual adjustment on screw and bolt adjustment | Frequency conversion continuously variable regulation |

| HGK10 | 10 | Φ300-2800 | Φ300×120 | 2×Φ290×25 | 6-60 | 2×0.55 | ||

| HGK20 | 20 | Φ500-3500 | Φ350×120 | 2×Φ340×35 | 6-60 | 2×1.1 | ||

| HGK40 | 40 | Φ600-4200 | Φ400×120 | 2×Φ390×45 | 6-60 | 2×1.5 | ||

| HGK60 | 60 | Φ750-4800 | Φ450×120 | 2×Φ440×60 | 6-60 | 2×2.2 | ||

| HGK80 | 80 | Φ850-5000 | Φ500×120 | 2×Φ490×70 | 6-60 | 2×3 | ||

| HGK100 | 100 | Φ1000-5500 | Φ500×120 | 2×Φ490×100 | 6-60 | 2×4 | Bolt adjustment | |

| HGK150 | 150 | Φ1100-6000 | / | Φ620×220 | 6-60 | 2×4 | ||

| HGK250 | 250 | Φ1200-7500 | / | Φ660×260 | 6-60 | 2×5.5 | ||

| HGK400 | 400 | Φ1200-7500 | / | Φ750×320 | 6-60 | 2×7.5 | ||

| HGK500 | 500 | Φ1200-7500 | / | Φ750×400 | 6-60 | 2× | ||

Related Names

Adjustable Welding Roll Frame | Conventional Welding Frame with Wheel | Pipe Fabrication Roll

Scan QR to Read

Links:https://globefindpro.com/products/87539.html

Links:https://globefindpro.com/products/87539.html

Recommended Products

Hot Products