SSAW Pipe / Spiral Submerged Arc Welded Steel Pipe

SSAW Pipe/Spiral Submerged Arc Welded Steel Pipe

Technical Specifications

Type | SSAW Steel Pipe |

Wall Thickness | Sch5s, Sch10s, Sch10, Sch20, Sch30, Sch40s, STD, Sch40, Sch60, Sch80s, XS, Sch80, Sch100, Sch120, Sch140, Sch160, XXS, etc. |

Implementation Standard | National Standard: GBAmerican Standard: ANSI,API,ASTMJapanese Standard: JISBritish Standard: BSGerman Standard: DIN, etc. |

Material | ASTM: A234-WPB,WP1, WP5, WP9, WP11, WP12, WP22, WP91, WP92, A420,WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WP304, WP304L, WP304H, WP316, WP316L, WP321, WP347, WP347H DIN: ST37.0, ST35.8, ST45.8, S235JR, P235GH, P265GH, 10CRMO910, 15CRMO, 12CR1MOV JIS: JISG3454, STPG370, STPG410, etc. |

Package | The steel pipe can be bundled up, binned, bundled up with fat coating, or binned with fat coating and other customized package. |

The spiral submerged arc welded steel pipe is made of low carbon structural steel or low alloy structural strip steel, which is rolled up into pipe blank in certain spiral line angles and then welded. It is mainly used for transporting petroleum and natural gas. In addition, we adopt electro connecting pressure gauge to control the pressure when the conveyer press the hydro-cylinder so as to ensure the stable transportation of the strip steel. Yet the weld gap control device provides a strict control on pipe diameter, unfitness of butt joint and welding gap to meet various production requirements.

With American Lincoln electric welder with single or double wire submerged arc welding, this product is welded conforming to standard on inside and outside welding. The weld joint will be checked with online continuous automatic ultrasonic flaw detector to ensure 100% nondestructive testing. If there are some defects, it will alarm and spray marks automatically so that the workers will adjust the parameters to remove the problems. According to certain production and processing procedures, our product will be made with excellent properties. Moreover, it will perform perfectly if customers use it with certain technical parameters.

Features

1.This spiral submerged arc welded steel pipe can be made in different outer diameter with strip steel in same wide.

2. It performs excellent straightness with precise size. Moreover, the inside and outside weld joints improve the stiffness of the product so that it has no need to be shaped in diameter and straightened after welding.

3. Our product can easily realize mechanized, automated and serialized production.

4. It is small in size, space saving and can be made in high efficiency with low investment.

5. Compared with LSAW type in same size, this product has longer weld joint on unit length so that it has relatively lower productivity.

Links:https://globefindpro.com/products/87639.html

-

Butt Welded Steel Tube

Butt Welded Steel Tube

-

LSAW Pipe / Longitudinal Submerged Arc Welded Steel Pipe

LSAW Pipe / Longitudinal Submerged Arc Welded Steel Pipe

-

Hot Rolled Seamless Steel Pipe

Hot Rolled Seamless Steel Pipe

-

Steel Eccentric Reducer

Steel Eccentric Reducer

-

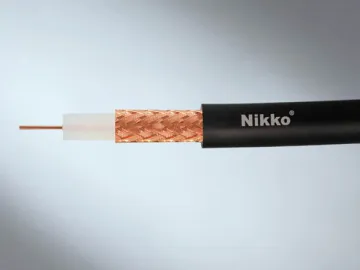

RG 58U Coaxial Cable

RG 58U Coaxial Cable

-

RG 8U Coaxial Cable

RG 8U Coaxial Cable

-

Forged Steel Reducing Cross Fitting

Forged Steel Reducing Cross Fitting

-

Straight 4 Way Cross Fitting

Straight 4 Way Cross Fitting

-

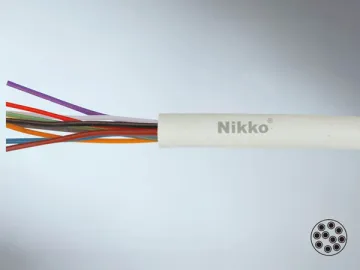

RG6U Coaxial TV Cable With Telephone Wire

RG6U Coaxial TV Cable With Telephone Wire

-

RG 59U Coaxial Cable

RG 59U Coaxial Cable

-

8 Pair Telephone Cable

8 Pair Telephone Cable

-

Steel Equal Tee Fitting

Steel Equal Tee Fitting