UL1569 Wire

UL1569Wire

1

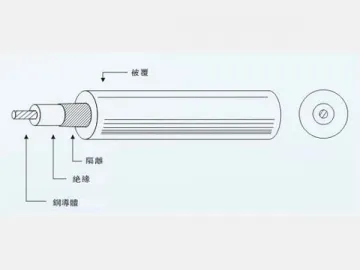

Constructed of stranded bare or tined copper conductor and lead-freePVC insulation, the UL1569 wire has resistance to acid, alkali and oil and ismoisture and mould proof, which is suitable for the internal wiring of commonelectrical and electronic equipment. In addition, the insulation is uniform in thickness and isthus easy to peel and cut off.

Our product meets the standards of UL758, UL1581 and CSA C22.NO.210. Its ratedvoltage is 300V and the rated temperature is 80℃, 90℃ or 105℃.

2

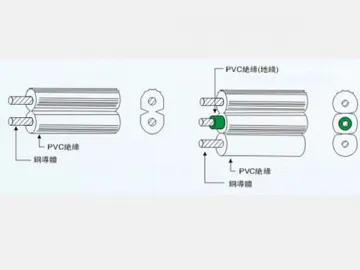

Copper Conductor

PVC PVC Insulation

| Type | Conductor | Insulation | Standard length | Conductor resistance at 20℃ | ||||

| AWG | Construction | Thickness | Overall diameter | British system | Metric system | Uncoated copper | Tinned copper | |

| NO./mm | mm | mm | Ft/coil | M/coil | Ω/Km | Ω/Km | ||

| UL1569 stranded wire | 30 | 7/0.102 | 0.41 | 1.15±0.05 | 2000 | 610 | 354 | 381 |

| 28 | 7/0.127 | 0.41 | 1.25±0.05 | 2000 | 610 | 223 | 239 | |

| 26 | 7/0.160 | 0.41 | 1.35±0.05 | 2000 | 610 | 230 | 150 | |

| 24 | 11/0.160 | 0.41 | 1.50±0.05 | 2000 | 610 | 87.6 | 94.2 | |

| 22 | 17/0.160 | 0.41 | 1.65±0.05 | 2000 | 610 | 55.4 | 59.4 | |

| 20 | 21/0.180 | 0.41 | 0.80±0.10 | 2000 | 610 | 34.6 | 36.7 | |

| 18 | 34/0.180 | 0.41 | 2.05±0.10 | 2000 | 610 | 21.8 | 23.2 | |

| 17 | 42/0.180 | 0.41 | 2.20±0.10 | 2000 | 610 | 17.3 | 18.3 | |

| 16 | 26/0.254 | 0.41 | 2.35±0.10 | 1000 | 305 | 13.7 | 14.6 | |

| 14 | 41/0.254 | 0.51 | 3.00±0.10 | 1000 | 305 | 8.62 | 8.96 | |

| 12 | 65/0.254 | 0.51 | 3.50±0.10 | 1000 | 305 | 5.43 | 5.64 | |

| 10 | 105/0.254 | 0.76 | 4.60±0.01 | 1000 | 305 | 3.409 | 3.546 | |

The UL1569 wireproduced by our company has stable performance. Its insulation thickness is 0.41mm, 0.51mm or 0.76mm.The outer diameter of the product with the insulation thickness of 0.76mm is 4.60±0.01mm and each coil is 305m. 105 bare or tinned copper conductors with thediameter of 0.254mm areadopted and the resistance at 20℃is 3.409 Ω/Km for the uncoated copper and 3.546 Ω/Km for thetinned copper. Our product has passed UL VW-1 and CSA FT1 horizontal andvertical flame test and is thus safe to use, which is an ideal product forelectrical and electronic equipment.

Links:https://globefindpro.com/products/88061.html