Fuel Gas Decorating Ceramic Kiln

Fuel Gas Decorating Ceramic Kiln

The fuel gas decoratingceramic kiln is mainly used in decorating firing and overglaze decorating fordomestic ceramic and art ceramic. It can also be used in decorating and dryingof glasswork. The maximum temperature is 1,100℃.The production cycle is 40 to 50 days.

Technical Specification

| Length of Furnace | 30-60m, segmental |

| Maximum Service Temperature | 1,100℃ (adjustable) |

| Gas Power | 30-100 kilocalorie |

| Electric Power | 5-20 (kW/380V) |

| Fuel | Natural gas, coal gas, liquefied gas |

| Heating Method | Muffle heating with silicon carbide radiant plate at the bottom of the high temperature section of the furnace |

| Smoke Extraction Method | Chimney natural smoke extraction, residual-heat utilized (forced smoke extraction also available) |

| Nozzle | Imported power nozzle |

| Temperature Controlling Method | Automatic ignition, automatic temperature controlling, temperature adjustable, alarm on malfunction |

| Temperature Controlling Point | 4-8 points |

| Rollers | φ40-80mm alumina ceramic rollers |

| Driving Method | Helical Gears |

The fuel gas decorating ceramic kiln can greatly improvethe decorative effect and value of ceramic products. We have provided severalmodels. Customers can choose the best suited one to realize lower powerconsumption. Due to the reasonably designed outer circulation system, wasteheat recycling system, splat cooling system, and exhaust system, it becomes oneof the green ceramic kilns with greatly improved energy utilization.

Links:https://globefindpro.com/products/89446.html

-

TIG-315II Industrial Inverter DC TIG Welding Machine

TIG-315II Industrial Inverter DC TIG Welding Machine

-

TIG-400II Industrial Inverter DC TIG Welding Machine

TIG-400II Industrial Inverter DC TIG Welding Machine

-

Tubular Experimental Electric Furnace

Tubular Experimental Electric Furnace

-

Thermocouple

Thermocouple

-

High Precision Glass Cutting Machine

High Precision Glass Cutting Machine

-

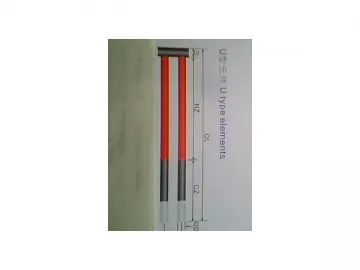

Silicon Carbide Rod

Silicon Carbide Rod

-

Lift Type Experimental Electric Furnace

Lift Type Experimental Electric Furnace

-

Quartz Tube, Stainless Steel Heat Pipe

Quartz Tube, Stainless Steel Heat Pipe

-

Ceramic Floor Tile Fuel Gas Tunnel Kiln

Ceramic Floor Tile Fuel Gas Tunnel Kiln

-

Industrial Radiation Shield

Industrial Radiation Shield

-

1400℃ Fuel Gas Furnace

1400℃ Fuel Gas Furnace

-

Experimental Electrothermal Glass Melting Furnace

Experimental Electrothermal Glass Melting Furnace